Metal button switch convenient to mount and dismount

A button and switch technology, applied in the electrical field, can solve the problems of reduced work efficiency, reduced safety performance, switch falling off, etc., to improve installation efficiency, avoid potential safety hazards, and achieve the effect of tightening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

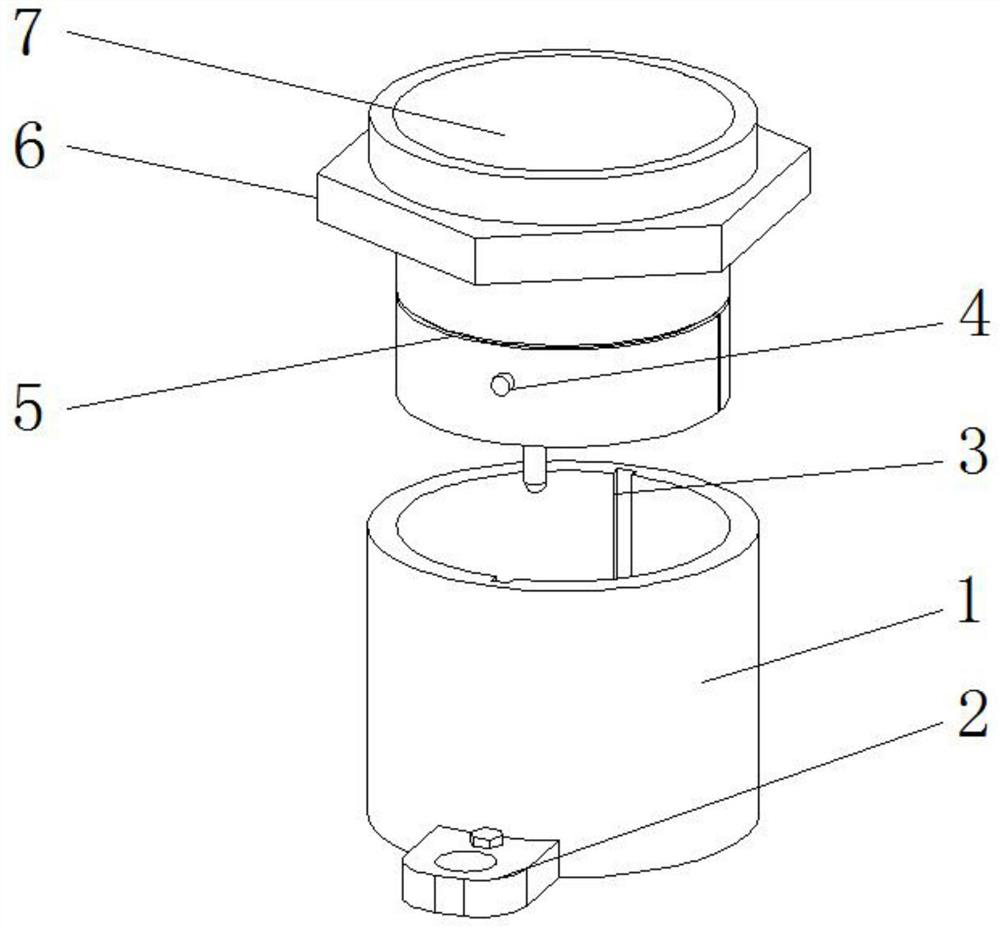

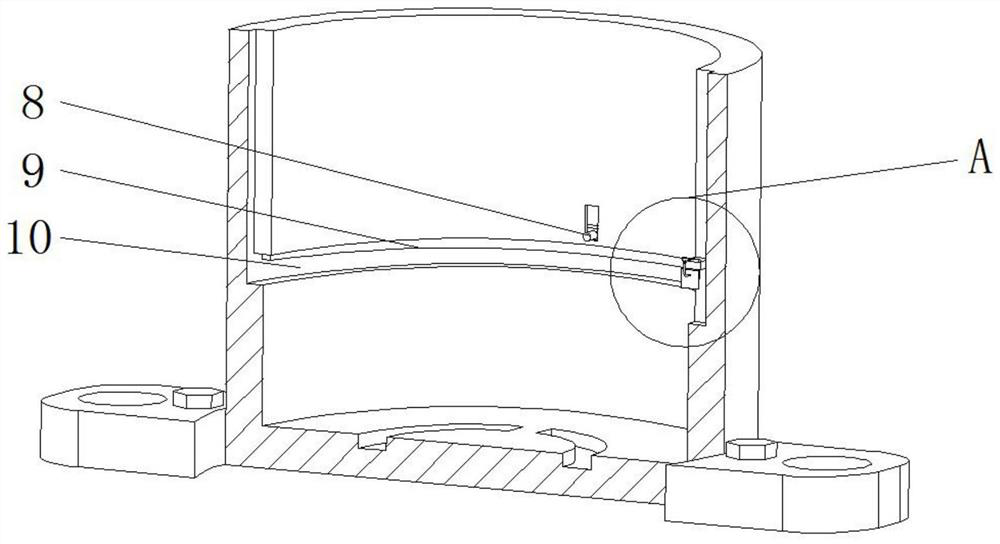

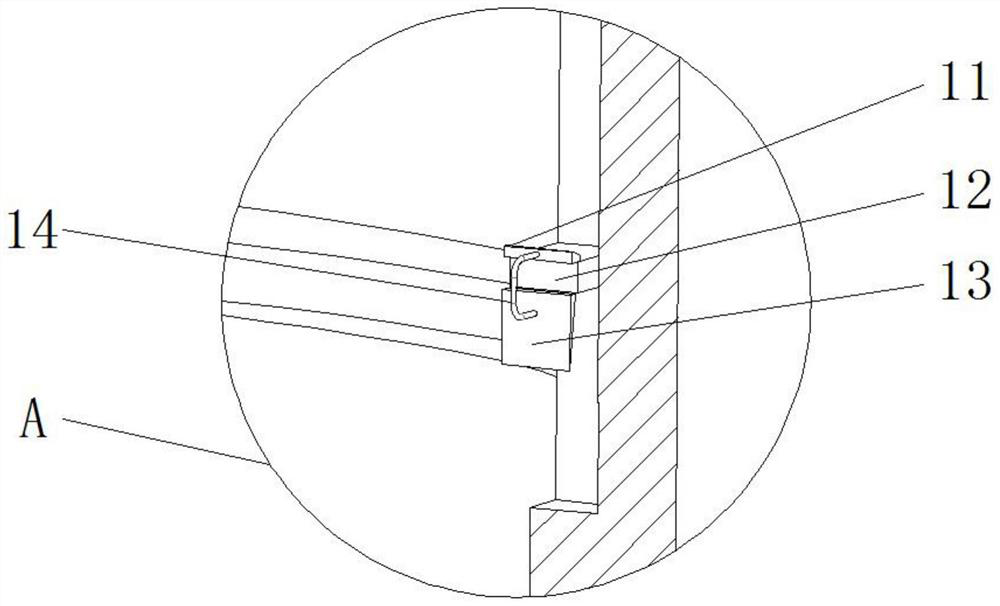

[0024] refer to Figure 1-4 , a metal button switch that is easy to install and disassemble, including a fixed tube 1, and two symmetrically arranged first chute 3s are opened on the arc-shaped inner wall of the fixed tube 1, and the arc-shaped inner wall of the fixed tube 1 is close to the two first chute 3 places Both are provided with fastening grooves 10, and the two fastening grooves 10 are respectively connected with the two first slide grooves 3, the top inner walls of the two fastening grooves 10 are provided with grooves, and the inner walls on one side of the two grooves slide A fastening plate 9 is connected, and the outer walls at the bottom of the two fastening plates 9 are slope structures. The outer walls on the opposite sides of the two fastening plates 9 are fixed with connecting rods 8 by bolts. The curved inner wall of the fixed pipe 1 is provided with two symmetrical settings. The through hole of the connecting rod 8 passes through, and the bottom of the in...

Embodiment 2

[0027] refer to Figure 1-3And 5, a metal button switch that is easy to install and disassemble, including a fixed tube 1, and the curved inner wall of the fixed tube 1 is provided with two symmetrically arranged first chute 3, and the curved inner wall of the fixed tube 1 is close to the two first chutes Fastening grooves 10 are provided at the three places, and the two fastening grooves 10 are respectively connected with the two first slide grooves 3, and the top inner walls of the two fastening grooves 10 are provided with grooves, and the inner walls on one side of the two grooves are Both fastening plates 9 are slidably connected, and the outer walls at the bottom of the two fastening plates 9 are slope structures. The outer walls on the opposite sides of the two fastening plates 9 are fixed with connecting rods 8 by bolts. Symmetrically arranged through holes are provided for connecting rods 8 to pass through. The bottom of the inner wall on one side of the two first chu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com