Fault-tolerant fault detection and protection method for electric drive assembly controller

A technology of fault detection and controller, which is applied in the field of signal diagnosis, can solve problems such as the inability to judge the authenticity of faults, and achieve the effects of avoiding startup failure, ensuring accuracy, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

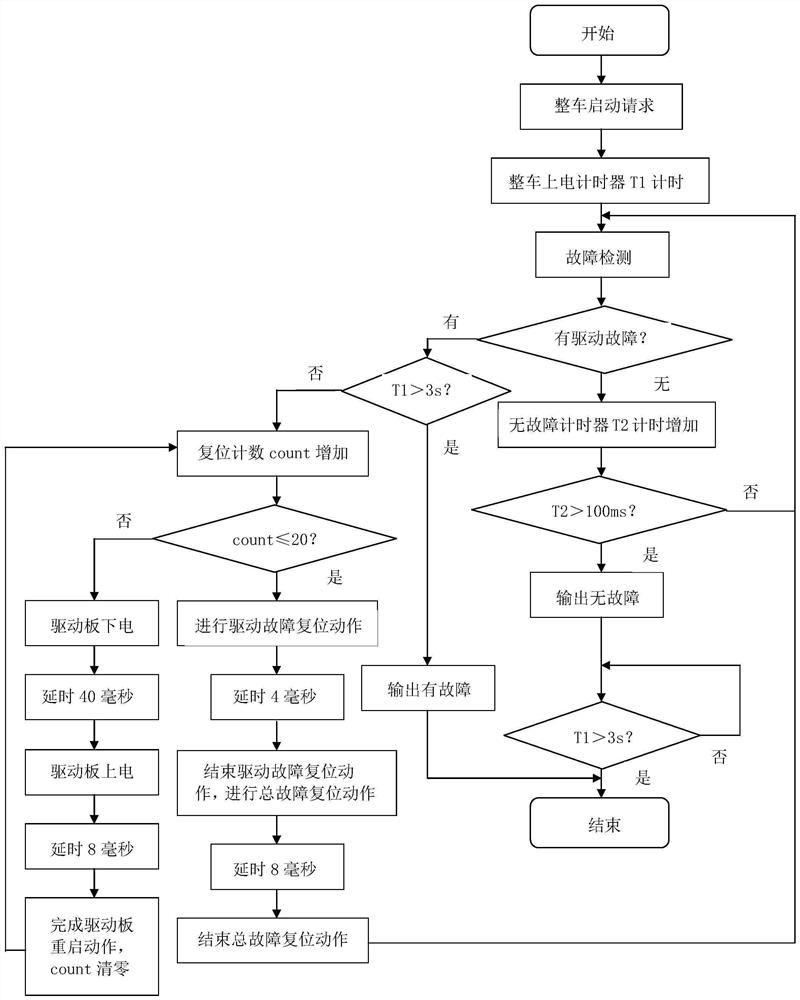

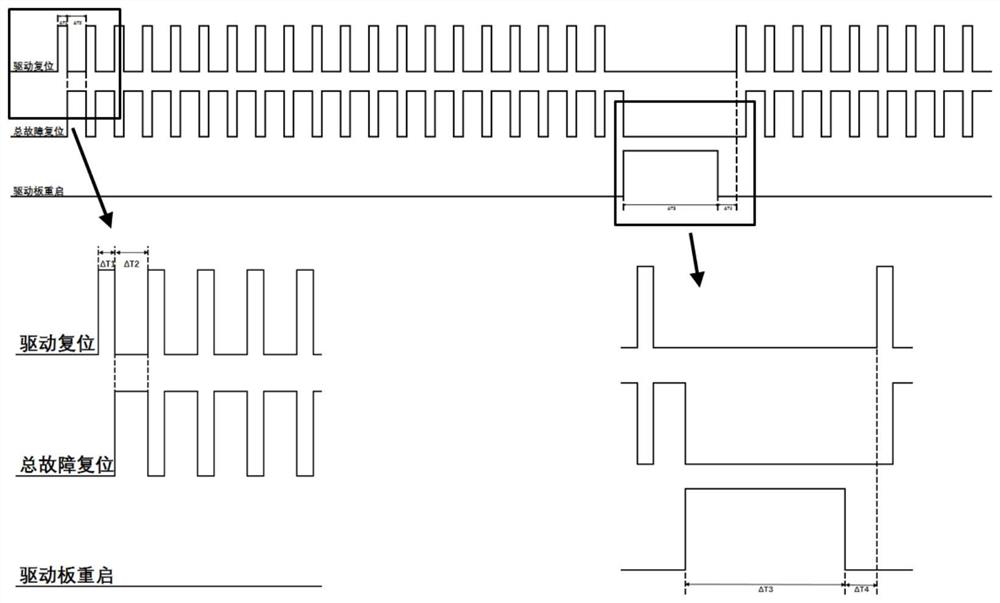

[0052] Embodiment 1: A fault-tolerant fault detection and protection method for an electric drive assembly controller in this embodiment, such as figure 1 shown, including the following steps:

[0053] A) set the time interval from receiving the request signal for starting the vehicle to the full start of the vehicle as T, in this embodiment T=3 seconds;

[0054] B) After receiving the request signal to start the vehicle, perform fault detection on the controller of the electric drive assembly;

[0055] C) Judging whether a fault is detected within the time interval T, if no fault is detected, then the output electric drive assembly controller has no fault, and the vehicle starts normally; if a fault is detected, proceed to step D);

[0056] Further, within the time interval T, if no fault is detected within the continuous T' time, the output electric drive assembly controller has no faults, and the fault detection is stopped, and the vehicle starts normally after the complet...

Embodiment 2

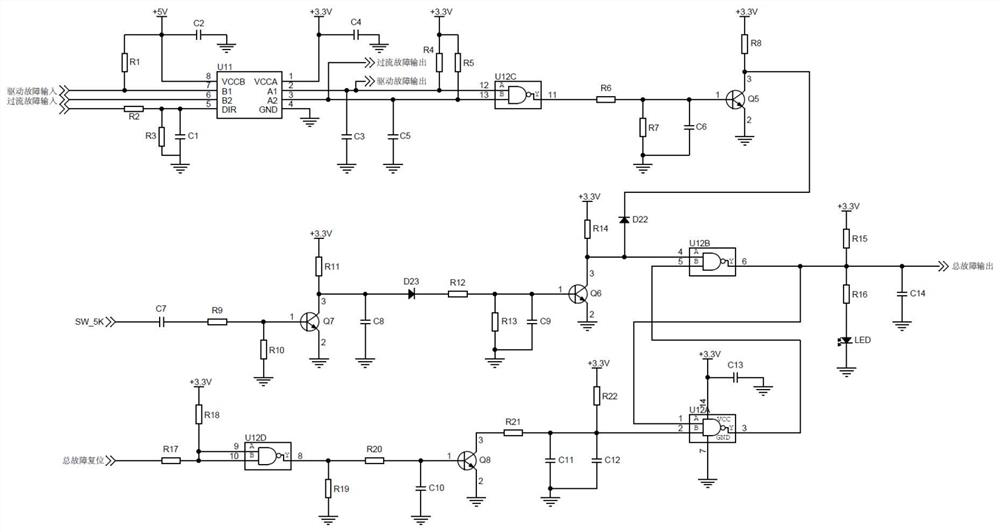

[0077] Embodiment 2: A fault-tolerant fault detection and protection method for an electric drive assembly controller in this embodiment, since the fault signal will attenuate during the process from the drive board to the voltage conversion chip, in order to ensure that the voltage conversion chip receives The quality of the fault signal, this embodiment performs attenuation compensation on the fault signal received by the voltage conversion chip U11 on the basis of Embodiment 1, specifically including:

[0078] ① Obtain the standard attenuation compensation function:

[0079] i) Make an attenuation compensation function acquisition model, the attenuation compensation function acquisition model includes a drive board fault signal output simulator, a communication cable and a voltage conversion chip, and the drive board fault signal output simulator can simulate an output drive board fault signal, The communication cable is excellent in manufacturing process and has the same s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com