High-precision detection device for aero-engine blade film holes and detection method thereof

An aero-engine and engine blade technology, which is applied in the field of aero-engines, can solve problems such as difficult processing, and achieve the effects of high detection reliability, improved work efficiency, and easy transfer and preservation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

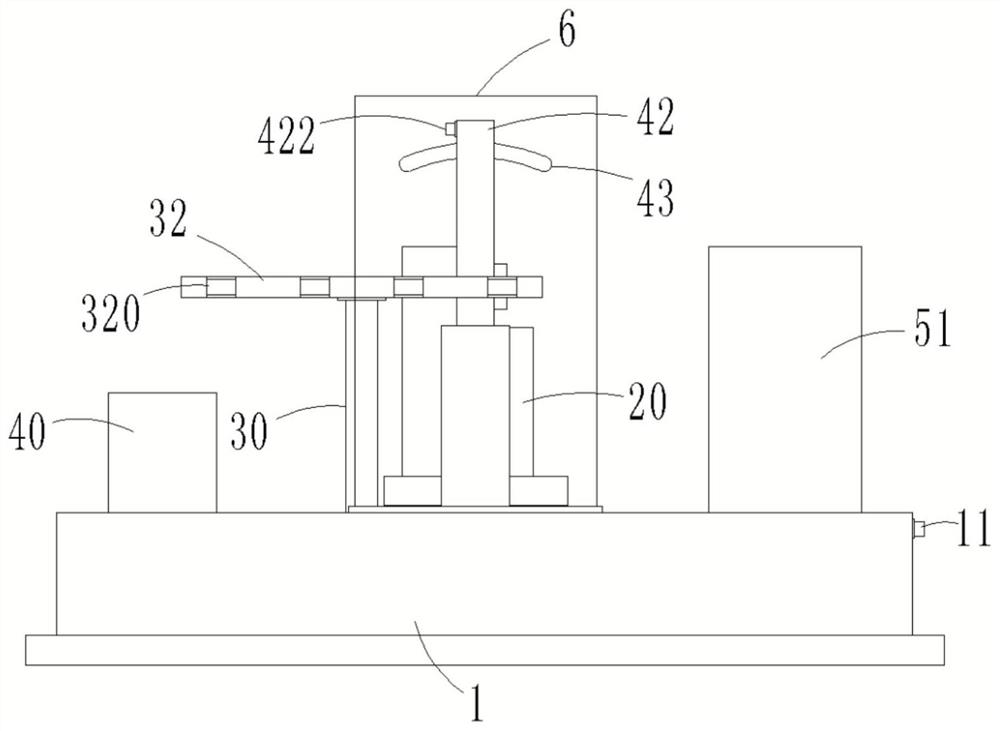

[0033] Embodiment 1: as figure 1 , 2 A high-precision detection device for an air film hole of an aero-engine blade is shown, including a detection platform 1, a blade fixing component 2, a switching component 3, a thermal imaging detection component 4 and a controller; the detection platform 1 is provided with a blade cooling component 5 ;

[0034] Such as figure 1 , 4 , 5, the blade fixing assembly 2 includes a moving seat 20, a clamping seat 21 and a fastening motor 22, the moving seat 20 is fixedly arranged on the detection platform 1, and the side wall of the moving seat 20 is provided with an air inlet port 200; There are two seats 21, two clamping seats 21 are arranged side by side up and down on the upper end of the moving seat 20, and the clamping seat 21 at the top of the moving seat 20 is engaged with the moving seat 20 by sliding, and the fastening motor 22 is fixedly arranged on the The top of the moving seat 20, the output shaft of the fastening motor 22 is p...

Embodiment 2

[0046] Embodiment 2: as figure 1 , 2 A high-precision detection device for the air film hole of an aero-engine blade is shown, including a detection platform 1, a blade fixing component 2, a switching component 3, a thermal imaging detection component 4 and a controller; Moving groove 10, detection platform 1 tail end is provided with moving motor 11, and the output shaft of moving motor 11 is provided with first leading screw 110, and first leading screw 110 runs through moving groove 10 horizontally, and with the inner wall rotation card of moving groove 10 connected; the detection platform 1 is provided with a blade cooling assembly 5, and the upper end of the detection platform 1 is slidingly clamped with a transparent protective cover 6, and the transparent protective cover 6 is located outside the thermal imaging detection assembly 4; by setting the transparent protective cover 6, on the one hand, it can During the detection process, the blades are kept warm to improve ...

Embodiment 3

[0059] Embodiment 3: as figure 1 , 2 A high-precision detection device for the air film hole of an aero-engine blade is shown, including a detection platform 1, a blade fixing component 2, a switching component 3, a thermal imaging detection component 4 and a controller; Moving groove 10, detection platform 1 tail end is provided with moving motor 11, and the output shaft of moving motor 11 is provided with first leading screw 110, and first leading screw 110 runs through moving groove 10 horizontally, and with the inner wall rotation card of moving groove 10 connected; the detection platform 1 is provided with a blade cooling assembly 5; the upper end of the detection platform 1 is slidingly clamped with a transparent protective cover 6, and the transparent protective cover 6 is located outside the thermal imaging detection assembly 4; by setting the transparent protective cover 6, on the one hand, it can During the detection process, the blades are kept warm to improve the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com