Drilling device for center point of end face of screw

A drilling device and center point technology, which is applied in the direction of boring/drilling, drilling/drilling equipment, metal processing equipment, etc., can solve the problem of lack of drilling machine position adjustment structure, laborious drilling, and poor drilling effect Ideal and other problems, to achieve the effect of high drilling efficiency, good drilling quality and improved precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

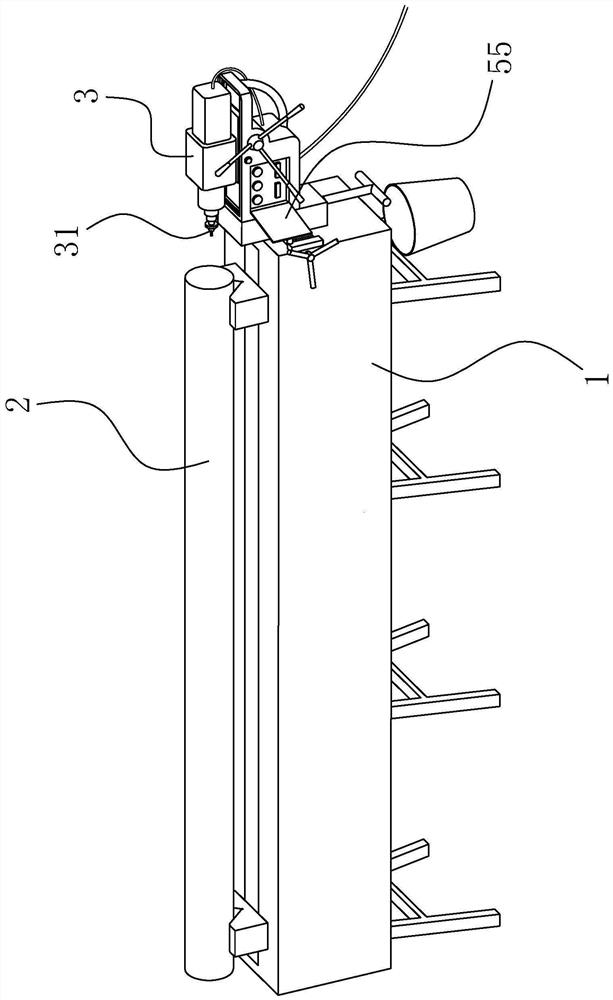

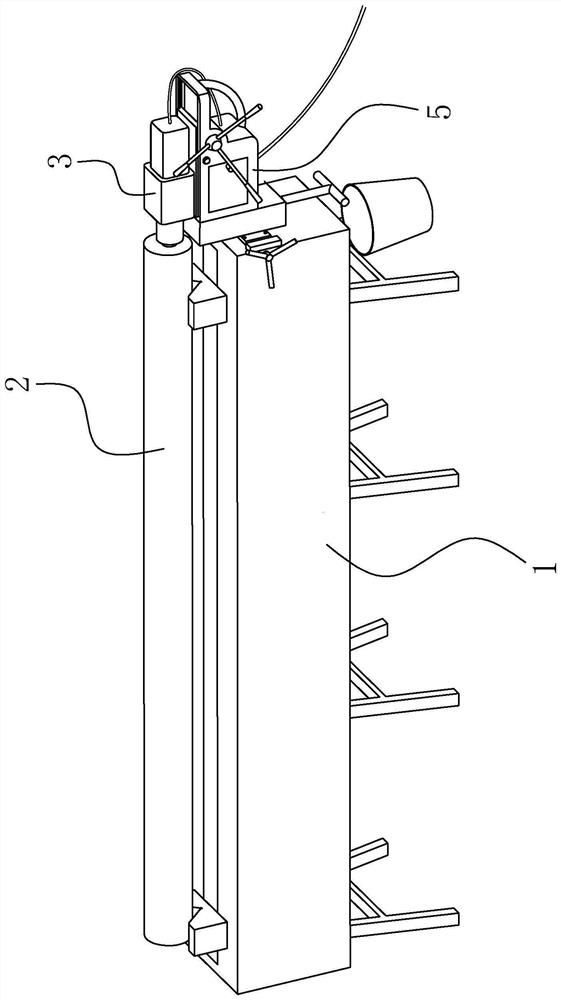

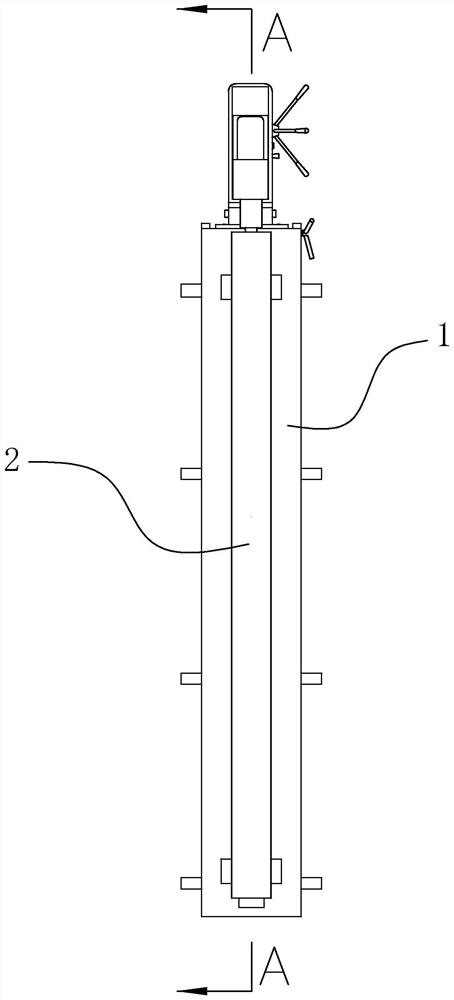

[0030] Such as Figure 1 to Figure 14 As shown, the drilling device at the center point of the screw rod end face of the present embodiment includes a bracket 1 capable of placing and positioning the screw rod 2 and a drill 3 capable of drilling holes at the end of the screw rod 2, and is arranged on the side wall at one end of the bracket 1 There is a first mobile frame 11 that can slide left and right along the side wall of the support and is positioned on the side wall of the support after sliding. The second mobile frame 12 on a mobile frame 11 is provided with the third mobile frame 13 that can slide back and forth relative to the second mobile frame 12 and is positioned on the second mobile frame 12 after sliding on the second mobile frame 12. The hole device 3 is arranged on the third mobile frame 13, and the drill bit 31 of the hole d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com