Filter pressing device for multi-stage filtration tandem feeding

A technology of stage filtration and feeding, which is applied in the field of multi-stage filtration and serial feed filter press devices, can solve the problems of inability to realize multi-gradient filtration, and achieve long-term high-efficiency filtration, increase the length of the filtration path, and prolong the filtration path. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

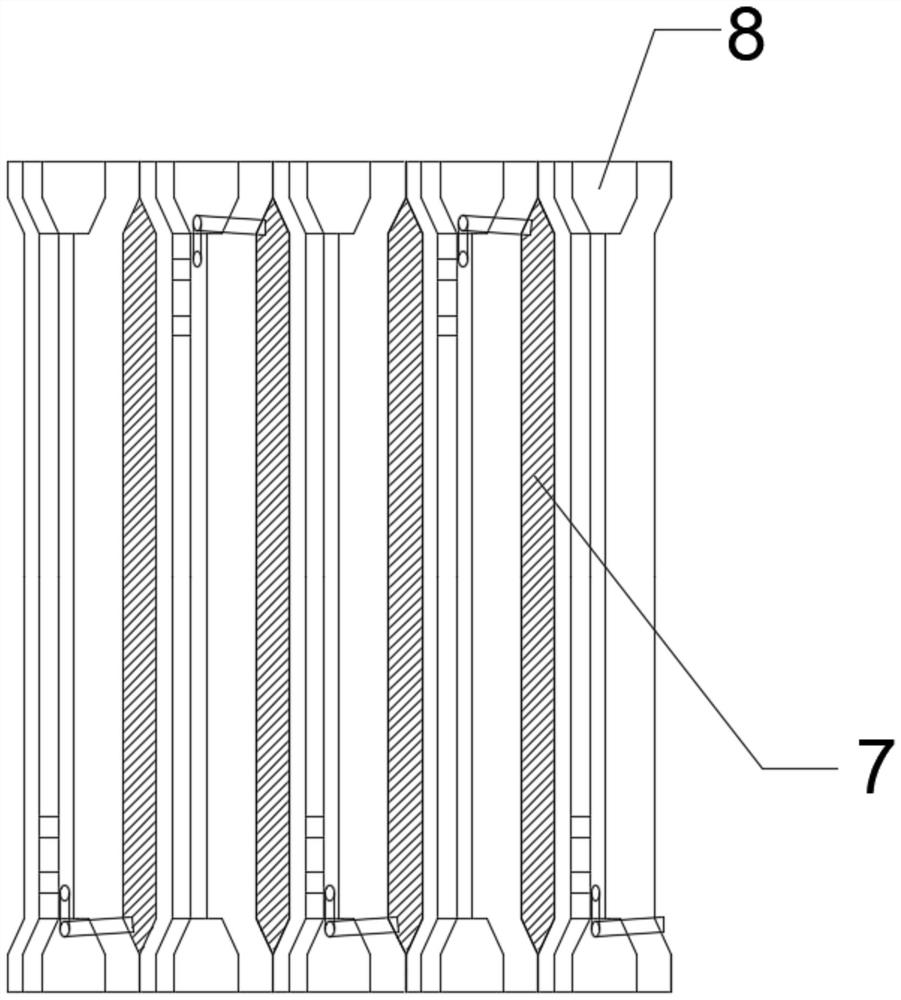

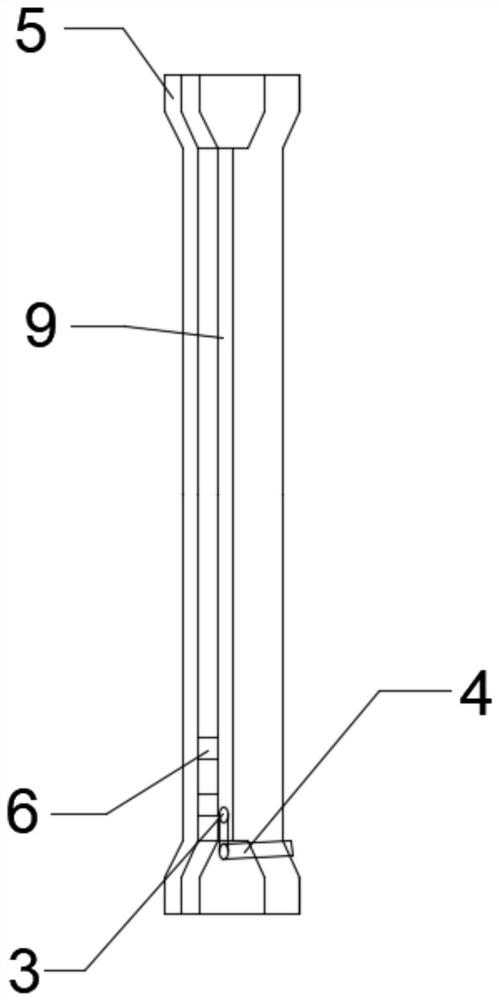

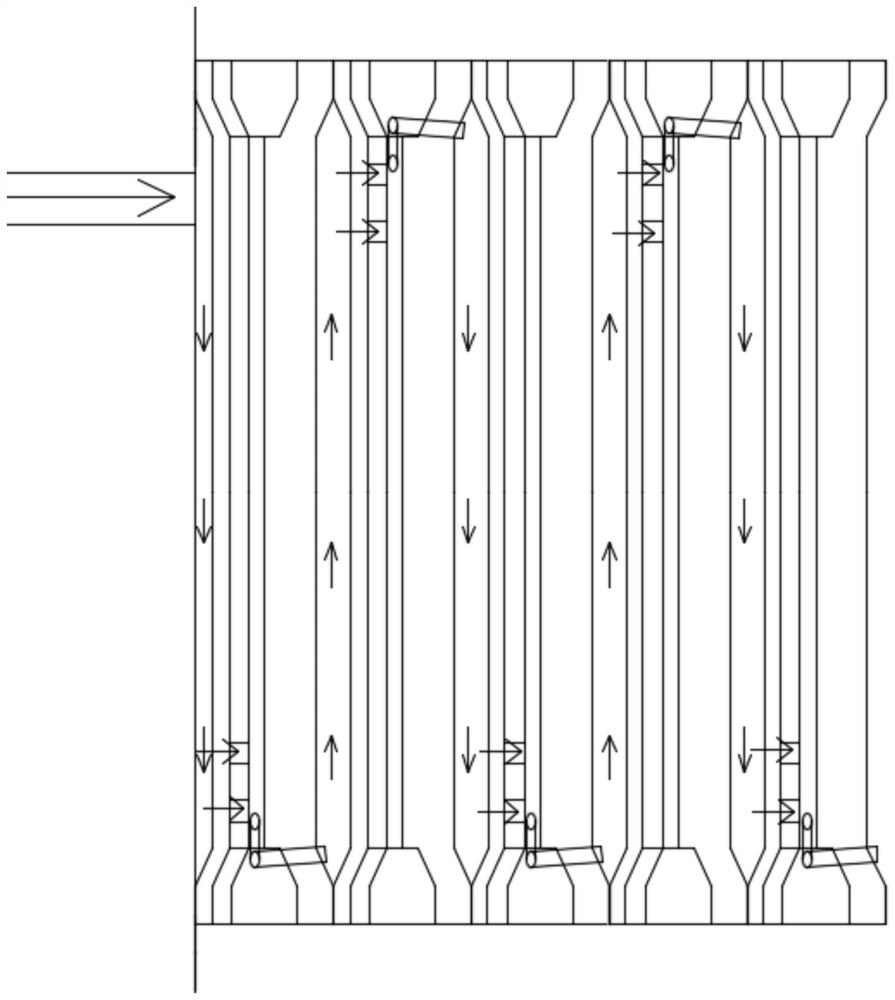

[0030] A filter press device for multi-stage filtration serial feeding, including several filter plates 8, inter-plate passages 7 are arranged between the filter plates 8, and filter cloth 5 is fixedly arranged on one side of the filter plates 8, The side of the filter cloth 5 close to the filter plate 8 is fixed with a filtrate collecting device, the filtrate collecting device is arranged on the side of the filter plate 8 for material filtration, and the filtrate collecting device is connected with a filtrate channel 4 , the filtrate channel 4 communicates with the inter-plate channel 7, the filtrate channel 4 is arranged at the end of the filter plate 8, and the filtrate channels 4 on each filter plate 8 are arranged alternately up and down.

[0031] The filtrate collecting device comprises a plate frame 1, on which several columns 6 are fixedly arranged, one end of the column 6 is in contact with the filter cloth 5, and the other end is connected with a liquid collection cha...

Embodiment approach

[0041] Taking the waste acid liquid absorbed by the spray tower as an example, filter cloths in the range of 1-100 microns are selected, and there are 10 filter cloths 5 in 10 levels, which are fixed on 10 filter plates 8 that are staggered and assembled, and the material delivery pressure of 1MPa is adopted. Feed to the filter press. During the waste liquid filtration process, the waste liquid is fed from the upper corner of the filter plate 8 and passes through the primary filter cloth 5 to achieve the filtration of coarse particles. The filtrate passes through the liquid collection chamber 9 and flows to the liquid collection tank 3 , through the inter-plate channel 7, enter the second-stage liquid collection chamber 9, and pass through 10 stages of filtration in turn, finally realizing the regeneration of waste liquid.

[0042] It should be noted that the filter press and its supporting structure are existing prior art, and will not be described in the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com