Motor

A base and rotor technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of different axial preload, angular contact ball bearing over preload, abnormal noise of bearing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

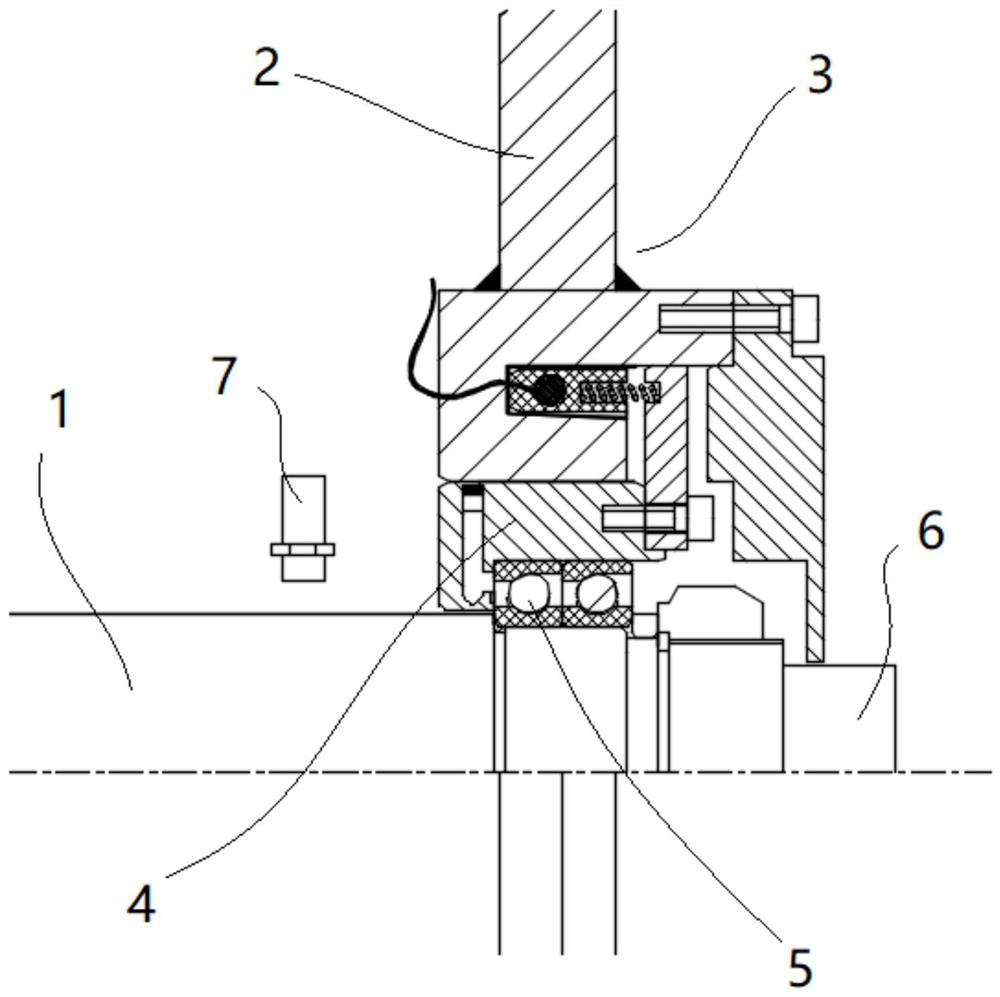

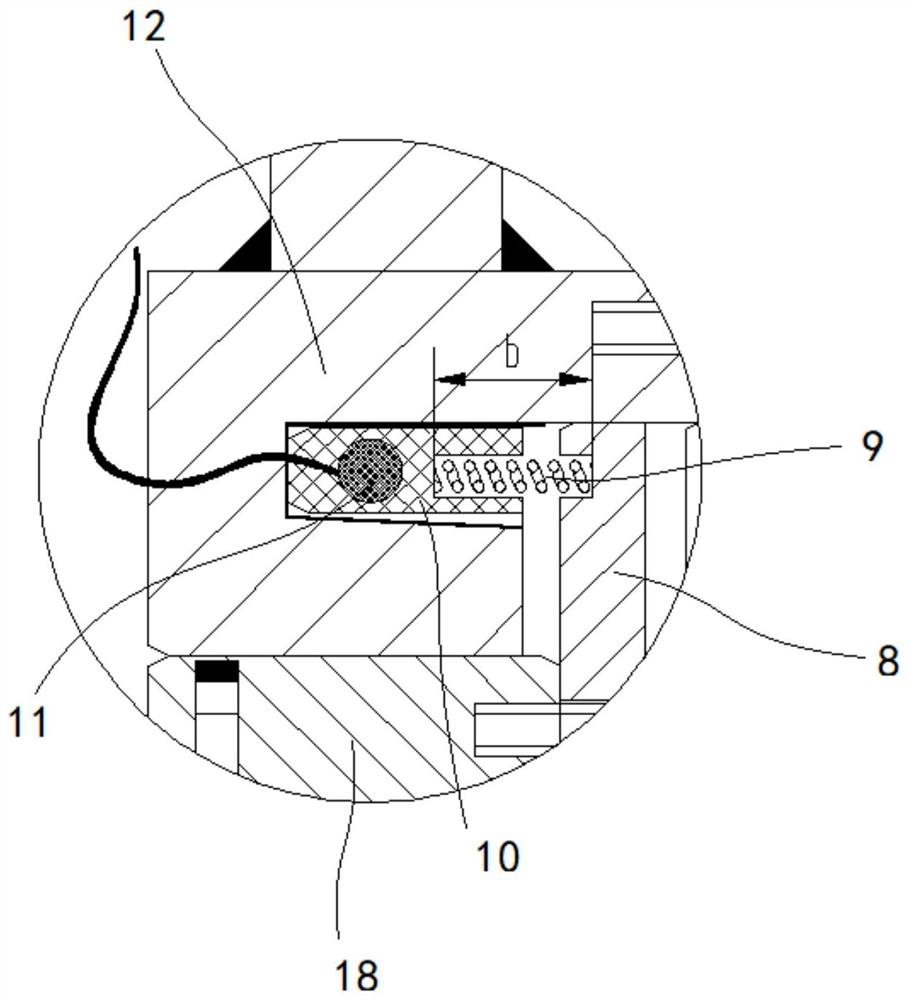

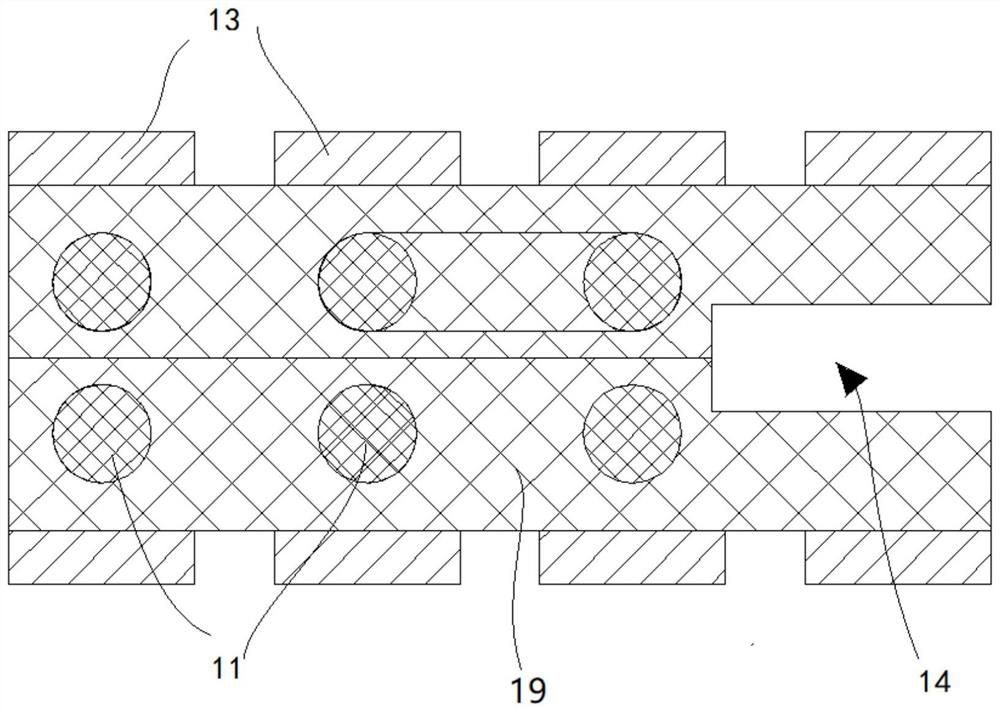

[0030] according to Figure 1 to Figure 5 The shown motor includes a rotor 1, a bearing 5, a bearing seat 4, a housing assembly 3, a base 10 and an elastic member 9;

[0031] The rotor 1 has an opposite extension end and a tail end 6, the bearing 5 is sleeved on the rotor 1 near the tail end 6, the bearing seat 4 cooperates with the housing assembly 3, and abuts against the end surface of the bearing 5 near the extension end;

[0032] The base 10 cooperates with the housing assembly 3. The elastic member 9 can generate elastic force along the axial direction of the rotor 1. The elastic member 9 has opposite first and second ends along the direction of the elastic force. The first end cooperates with the base 10, and the second end The two ends cooperate with the bearing seat 4;

[0033] The base 10 is provided with a heating element 11 , the base 10 can expand along the direction of the elastic force of the elastic member 9 when heated, and the base 10 can shrink opposite to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com