Device and method for testing linear translation dynamic performance of high-temperature superconducting magnetic levitation system

A high-temperature superconducting and dynamic performance technology, applied in the direction of magnetic performance measurement, measurement using levitation technology, and force component measurement, can solve problems such as inability to truly reflect maglev performance, and achieve the effect of solving track curvature deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

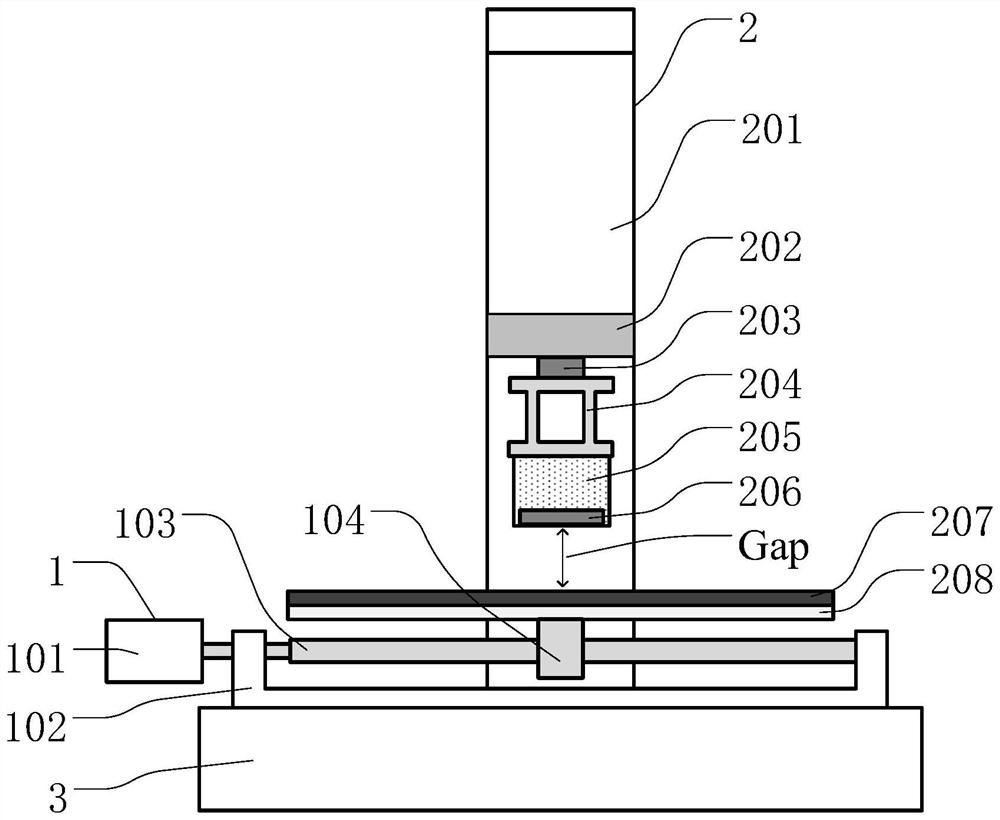

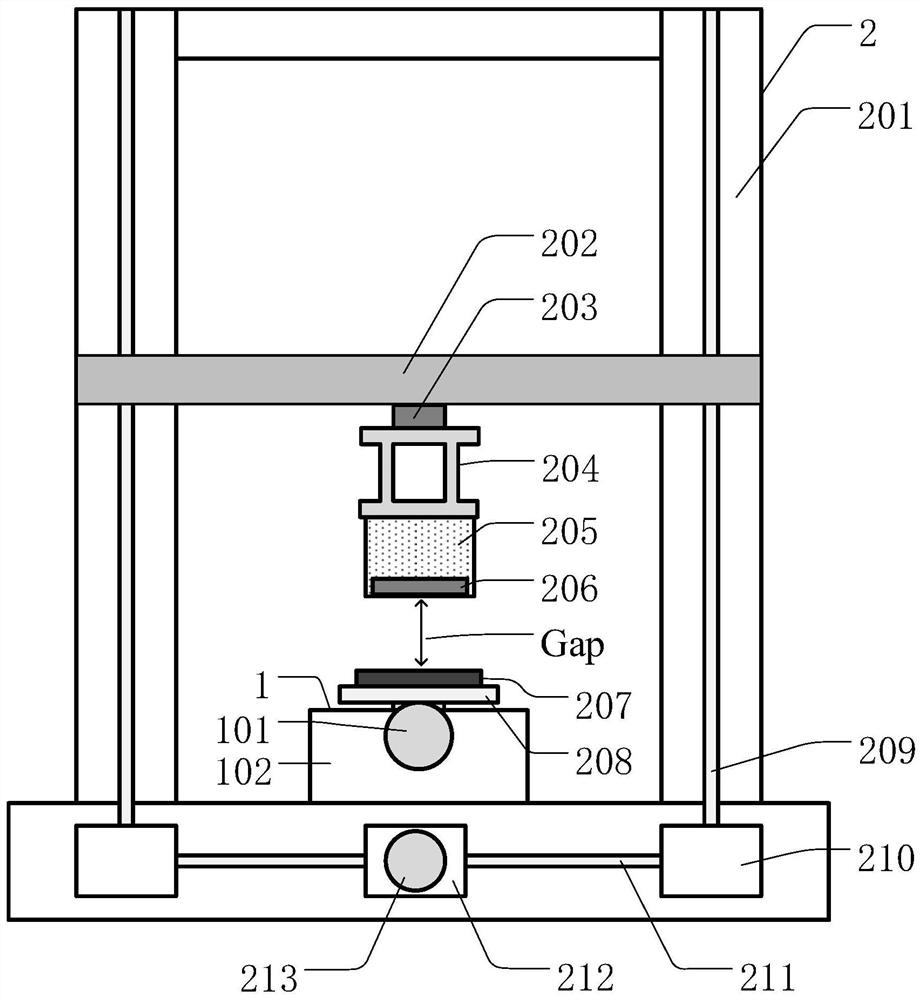

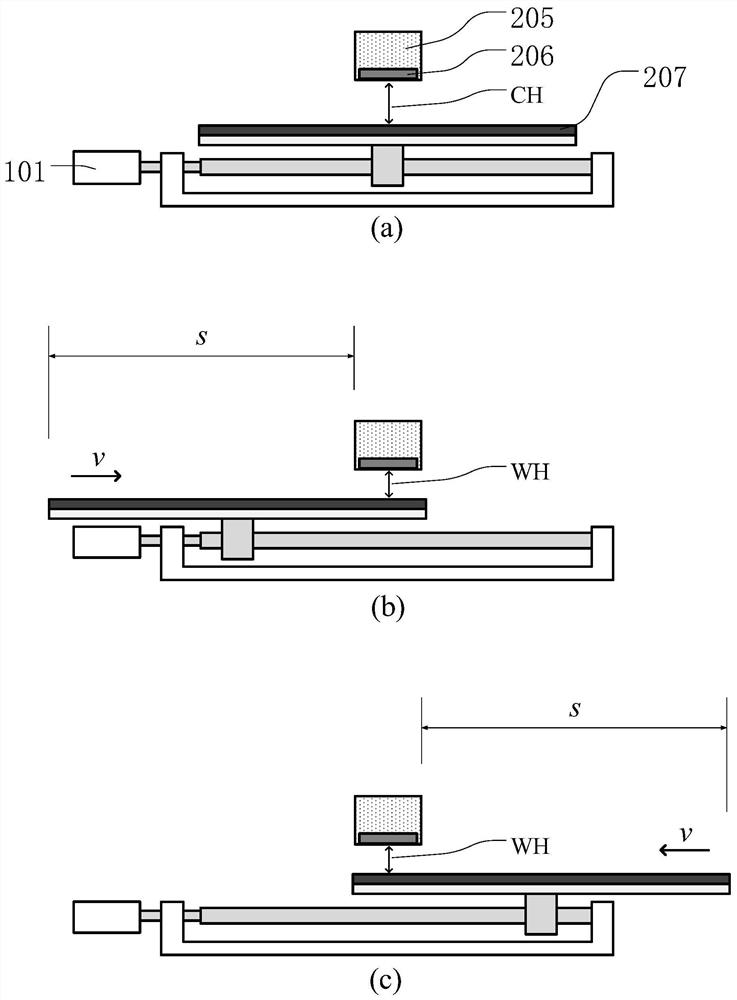

[0028] Such as figure 1 and 2 As shown, the present invention proposes a high-temperature superconducting maglev system linear translational dynamic performance test device, which includes a base 3, a horizontal slide module 1, a vertical slide module 2, a triaxial force sensor 203, a low-temperature Dewar 205 and Permanent magnet track 207;

[0029] The horizontal sliding table module 1 is arranged on the base 3, and the permanent magnetic track 207 is connected to the horizontal sliding table module 1 and is driven by the horizontal sliding table module 1 to perform linear translation reciprocating motion;

[0030] The low-temperature Dewar 205 is set above the permanent magnet track 207, the bottom of the low-temperature Dewar 205 is fixed with a high-temperature superconducting block 206, and the top of the low-temperature Dewar 205 is connected by a "II"-shaped connector 204 and a three-axis force sensor. 203 is connected with the vertical sliding table module 2, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com