Dual crushing device for bio-based organic fertilizer processing

A technology of crushing device and organic fertilizer, applied in grain processing, solid separation, sieving and other directions, can solve the problems of reduced screening and crushing efficiency, incomplete air blowing, etc., and achieve the effect of improving screening efficiency and avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments.

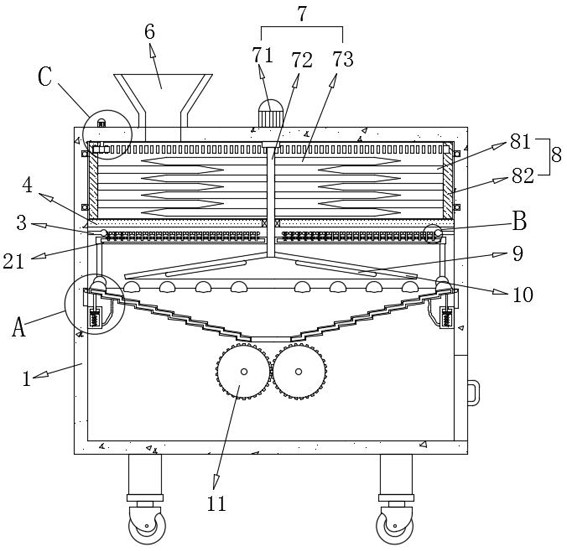

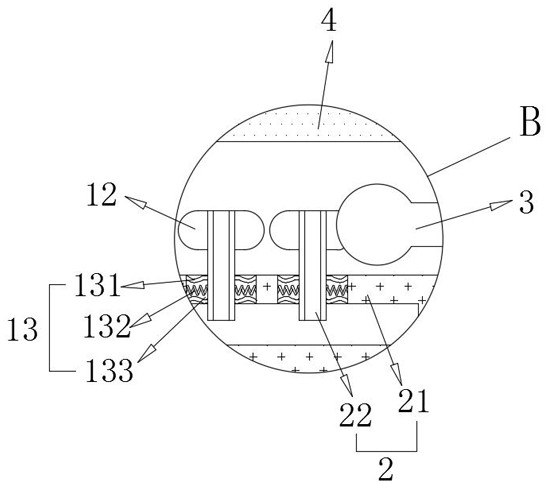

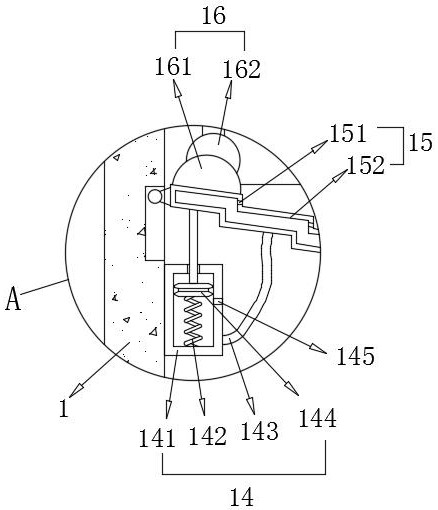

[0037] Refer Figure 1 to 4 A dual crushing device for biological organic fertilizer processing, including the box 1, and the outer wall of the casing 1 is attached, and the inner wall of the casing 1 is mounted, and the interior setting of the box 1 is provided. The first crushing mechanism 7 is configured to perform a preliminary crushing of a material located on the side of the screening member 4 near the upper feed funnel, the first crushing mechanism 7 including the shaft 72 and the first broken member 73, further comprising a drive shaft 72. The rotating second drive member 71, and the rotating shaft 72 extends to the screening member 4 away from one end of the side of t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap