Spring element and fire-resistant cover layer

A technology of spring elements and covering layers, applied in the direction of springs, springs/shock absorbers, springs made of plastic materials, etc., capable of solving problems such as danger, damage, and cracks in the covering layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

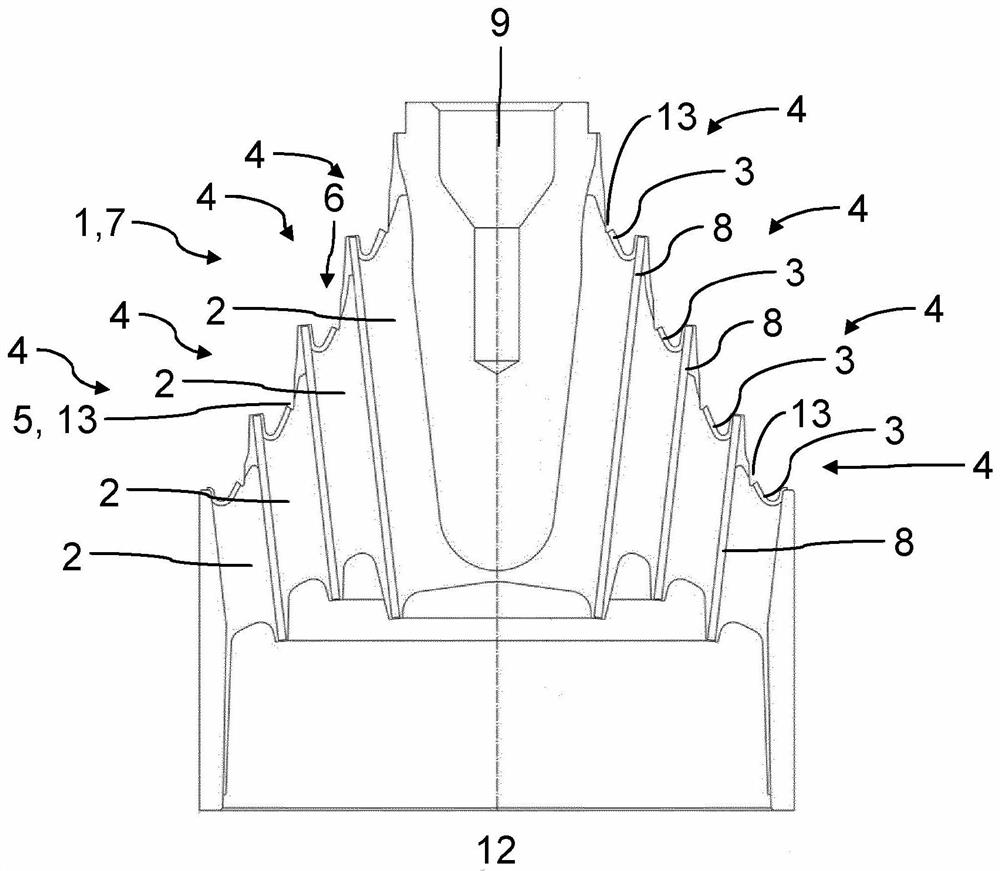

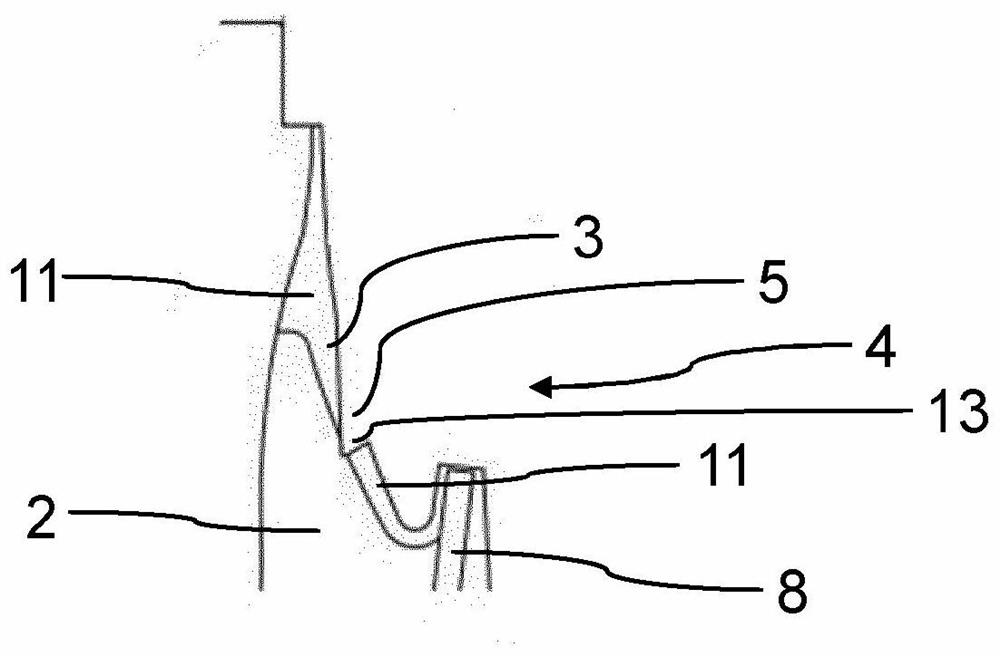

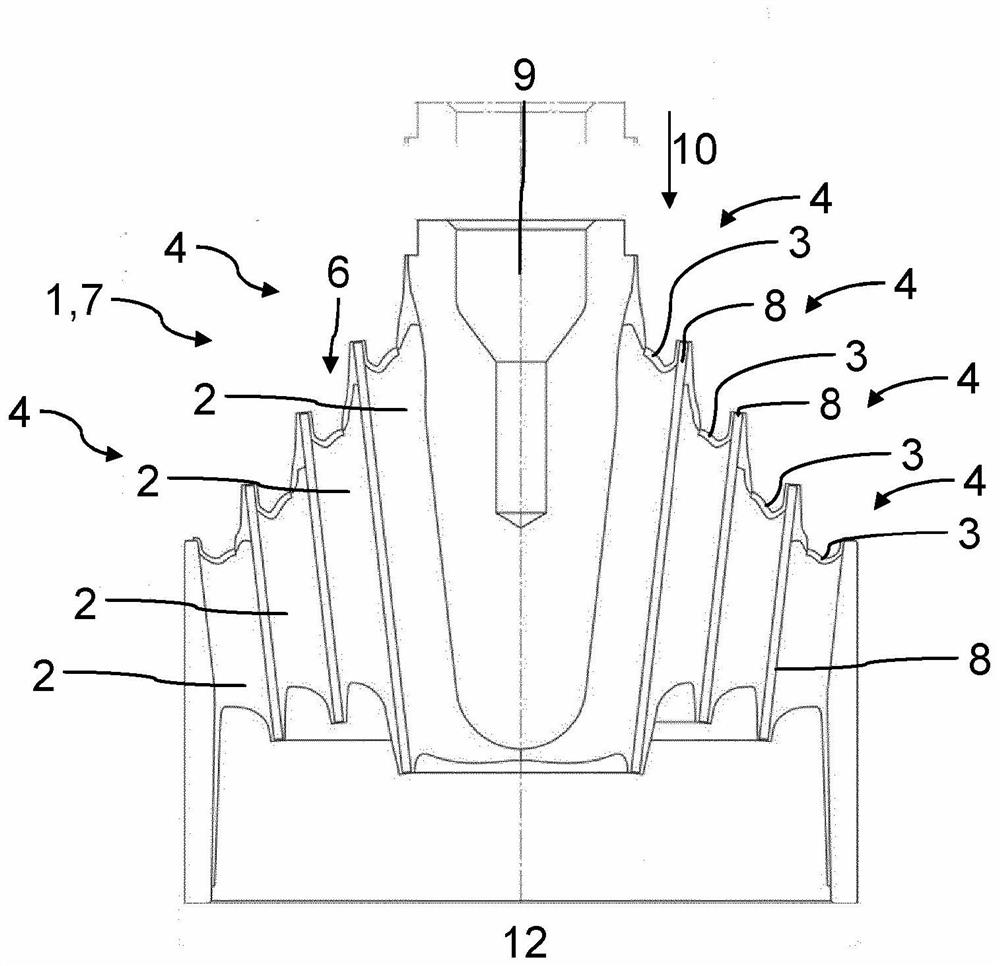

[0037] exist figure 1 with 4 A possible embodiment variant of the spring element denoted as a whole by 1 is shown in . The embodiment variants shown in the figures relate to conical springs 11 . Thus, the invention can be realized, for example, in a component for a main suspension in a chassis of a rail vehicle. However, the invention can also be realized, for example, in other components, in particular suspensions and / or shock absorbers for rail vehicles. The shown variants of embodiment are therefore to be understood only as possible examples and are therefore mainly used only for better elucidation of the invention.

[0038] The spring element 1 has a plurality of elastic damping bodies 2 which each support a flame-resistant covering layer 3 .

[0039] Suitable materials and compositions for producing the damping body 2 are already known and can also be used in connection with the invention. For example, damping bodies 2 made of one or more rubber materials are known. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com