Rail flaw detection car management map forming method

A rail flaw detection vehicle and map technology, which is applied in the field of rail engineering, can solve the problems of high manual labor intensity, missed reports of on-site review, and large positioning errors, and achieve the effects of reducing labor intensity, facilitating fine and automatic positioning, and avoiding missed inspections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

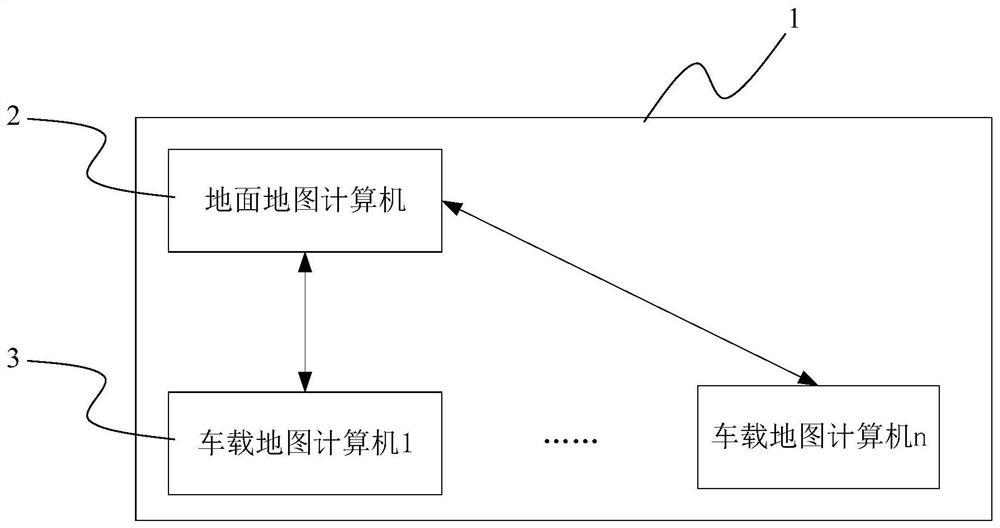

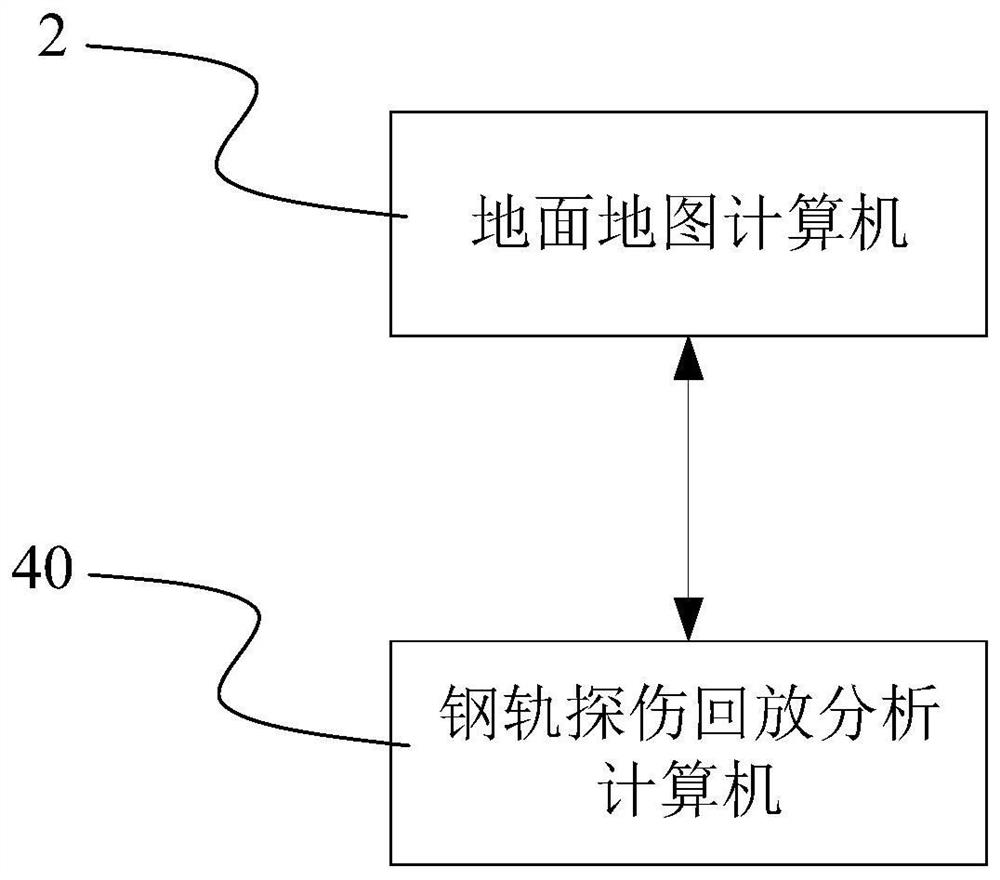

[0087] as attached figure 2As shown, an embodiment of the rail flaw detection vehicle management map system 1 based on the present invention is used for issuing flaw detection plan tasks, the vehicle map forms a track map, the rail flaw detection detection system 4 records and detects B-type maps, and the rail flaw detection playback analysis computer 40 for damage location analysis, which can well realize the refined maintenance of railway lines. The rail flaw detection vehicle management map system 1 specifically includes: a ground map computer 2 and a vehicle-mounted map computer 3, both of which are computer-based devices. The ground map computer 2 is used for storing, managing, applying and displaying the ground map, and the vehicle-mounted map computer 3 is used for storing, managing, applying and displaying the vehicle-mounted map. The specific working process of the rail flaw detection vehicle management map system 1 includes: entering the railway line database data ...

Embodiment 2

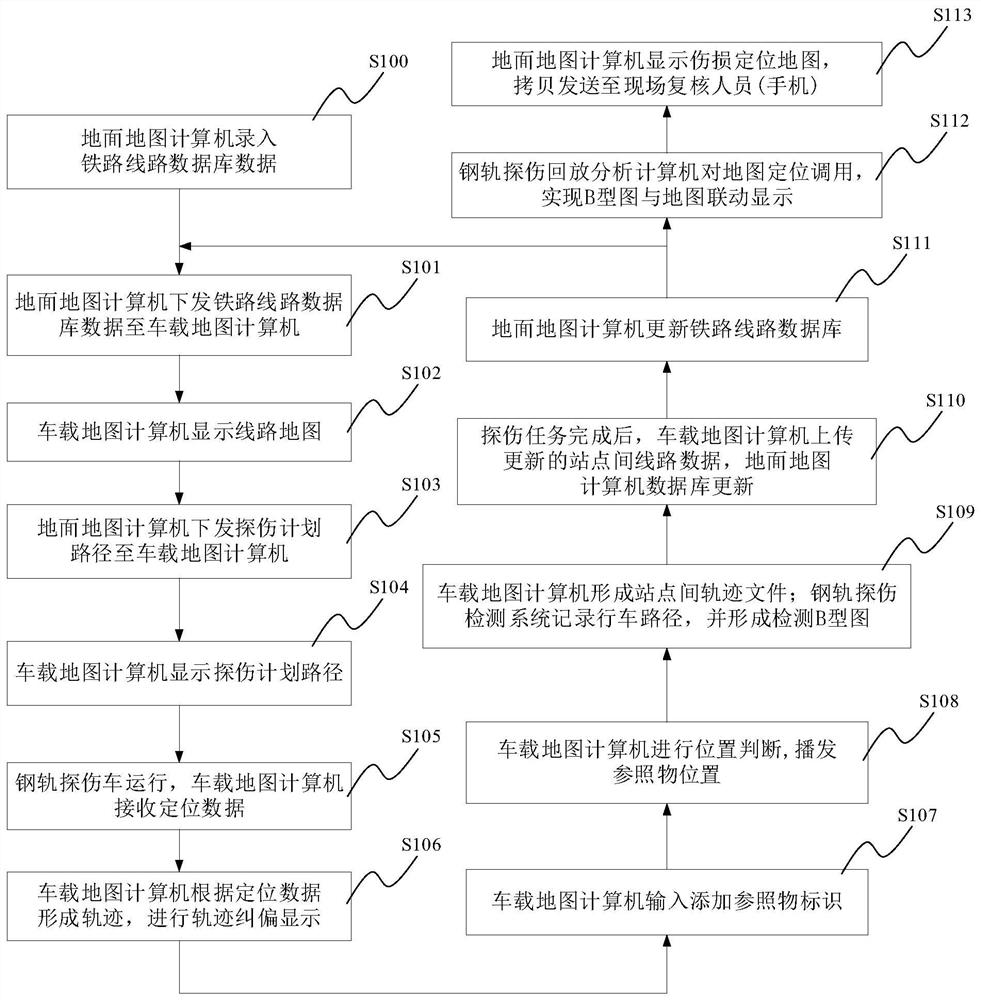

[0123] as attached figure 1 As shown, an embodiment of the method for forming a rail flaw detection vehicle management map of the present invention can automatically form a railway line vector map, call railway line data, display a specific path, and combine high-resolution mileage pulses to realize precise and automatic detection results of rail flaw detection vehicles Positioning, to solve the technical problems that the existing flaw detection vehicle needs to rely on manual input of reference object positioning every time it runs, resulting in high labor intensity, large positioning errors, and frequent on-site review omissions. The method specifically includes the following steps:

[0124] S100) The ground map computer 2 establishes a railway line database: the source of the railway line database is the updated data after the work flow in Embodiment 1 is completed, as shown in Table 3.

[0125] S101) The ground map computer 2 sends the railway line database data to the o...

Embodiment 3

[0172] A specific embodiment based on the rail flaw detection car management map formation method described in Embodiment 2 applied to offline map management, the railway line database has been fully formed, the on-board map computer 3 runs independently offline, and the ground map computer 2 does not need to be updated. The rail flaw detection system 4 records the running path and detects the B-type map file, and analyzes and locates the rail damage. The specific work flow of the rail flaw detection vehicle management map system 1 includes: the on-board map computer 3 displays the line map according to the complete railway line database shown in Table 6, as attached Figure 11 shown. The on-board map computer 3 edits the planned route table as shown in Table 7 below, and displays the planned route map. The rail flaw detection vehicle is running, and the on-board map computer 3 receives the positioning data and performs track correction and display. The on-board map computer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com