Rice processing technology

A rice processing and technology technology, applied in food processing, grain processing, energy-saving measures, etc., can solve problems such as affecting processing efficiency and consuming processing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

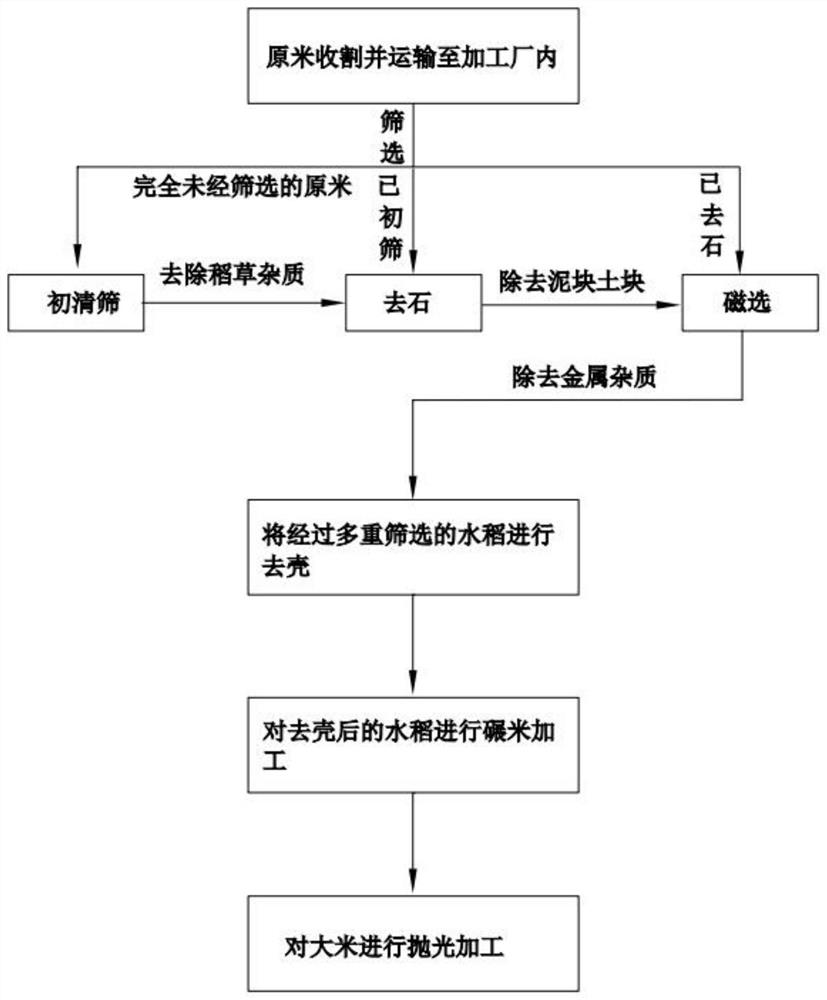

[0028] A rice processing technology, comprising the following steps: Step 1: adding the harvested raw rice to a screening device to filter the rice stalks; Step 2: performing multiple screenings on the raw rice after filtering the rice stalks to remove impurities; The impurity-removed rice is dehulled; Step 4: roughen and whiten the dehulled rice; Step 5: Polish the milled rice so that the starch on the surface of the rice forms a gelatinous layer to extend the shelf life.

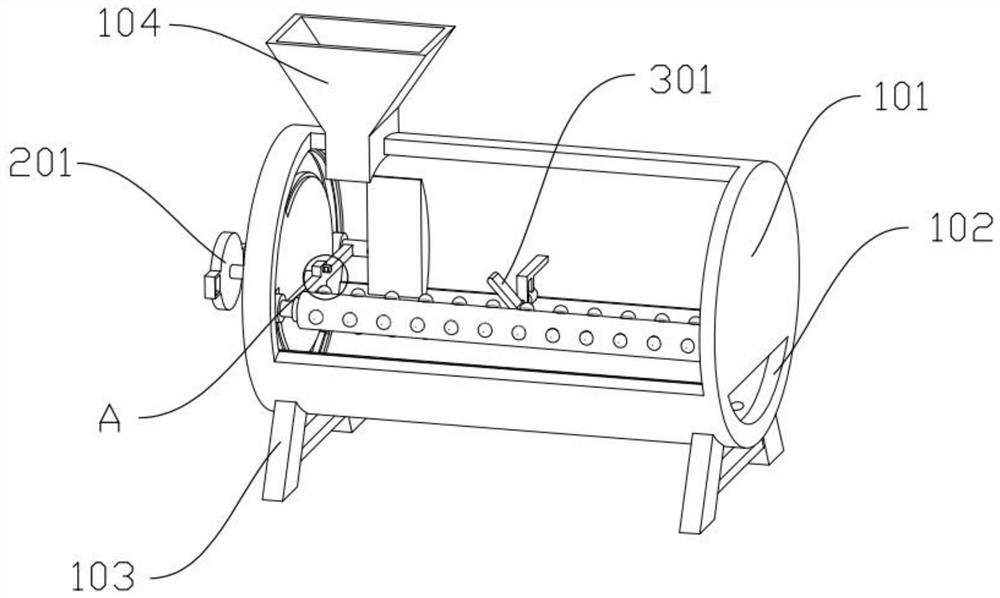

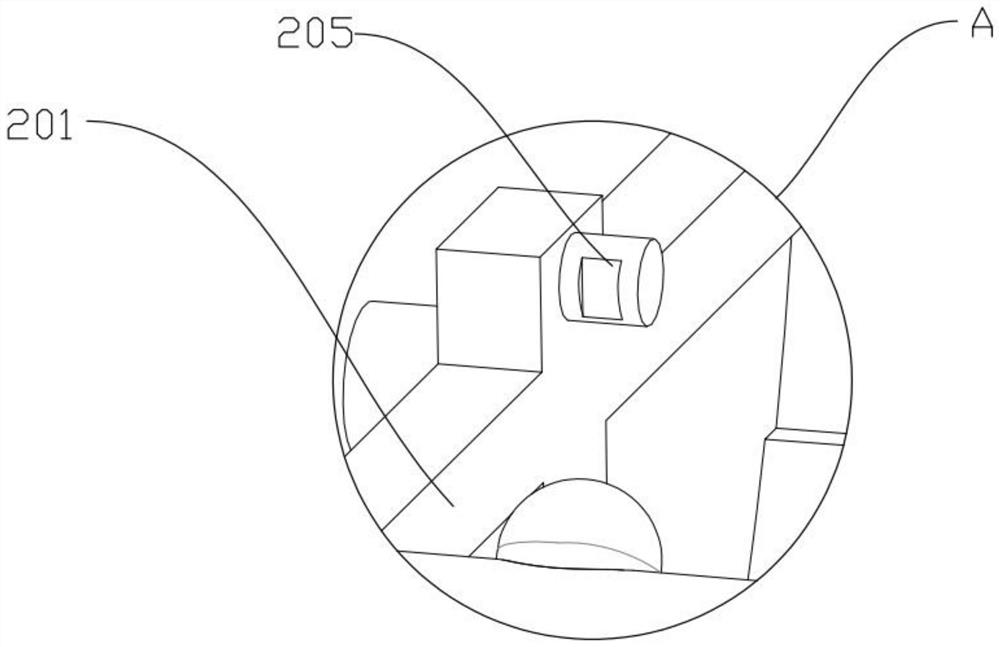

[0029] Also, as an example, such as figure 2 , Figure 5 , Figure 8 , Figure 12 As shown, this example solves the problem of filtering rice stalks in raw rice,

[0030] Since the unprocessed raw rice is harvested by harvesting machines and transported to the factory, there are impurities like rice stalks, mud, stones, and metals in the unfiltered raw rice. Therefore, before the raw rice is processed into finished products, The rice needs to be filtered and processed to filter out the impurities in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com