Method for determining safe separation condition of heatproof outsole

A technology for determining methods and separation conditions, which is applied in the field of aerospace and can solve problems such as the lack of safety conditions for determining the separation of the large bottom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0061] Specific implementation mode one: refer to figure 1 Specifically explain this embodiment, a method for determining the safety separation conditions of a heat-proof outsole described in this embodiment, including:

[0062] Step 1: According to the ballistic coefficient analysis of the detector and the outsole, determine the minimum separation speed for the safe separation of the outsole;

[0063] Step 2: According to the minimum separation speed of the safe separation of the large bottom, analyze the safety of the large bottom separation at different heights, and determine the minimum height of the safe separation of the large bottom;

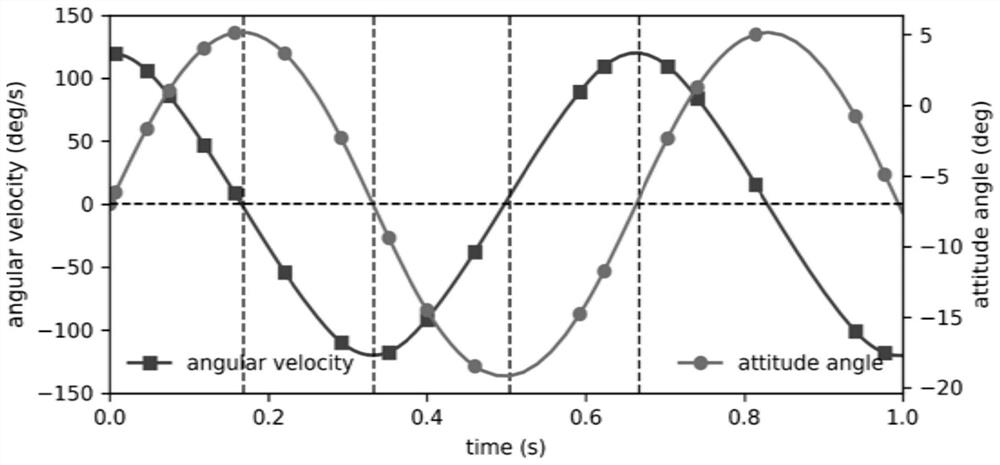

[0064] Step 3: According to the phase relationship between the angular velocity and the attitude angle when the outsole is separated, and the minimum separation speed and minimum height for the safe separation of the outsole, analyze the angular velocity and attitude angle of different phases to determine the phase requirements for the sa...

Embodiment

[0110] In order to verify the method for determining the safe separation conditions of the large bottom provided by the application, the steps described in the application have been carried out in an embodiment, 1. According to the ballistic coefficient analysis of the detector and the large bottom, determine the minimum separation speed of the safe separation of the large bottom;

[0111] Analyze the ballistic coefficient of the detector and the outsole, and obtain the aerodynamically unsafe Mach number range of [0.8,1.0]. The outsole separation simulation is carried out in the aerodynamically unsafe Mach number range, and the outsole separation is performed every 0.1Ma. Plot the velocity difference between the outsole and the probe / parachute system, as in Figure 4 shown. Figure 4 It is the speed difference between the outsole and the detector / parachute system corresponding to the outsole separation trigger condition 0.8~1.0Ma. The curves from left to right correspond to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com