Self-adaptive anti-seismic hanging bracket

A self-adaptive, hanger technology, applied in the direction of pipeline supports, pipes/pipe joints/fittings, mechanical equipment, etc., can solve problems such as pipeline falling, damage, and safety hazards, and achieve good earthquake resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

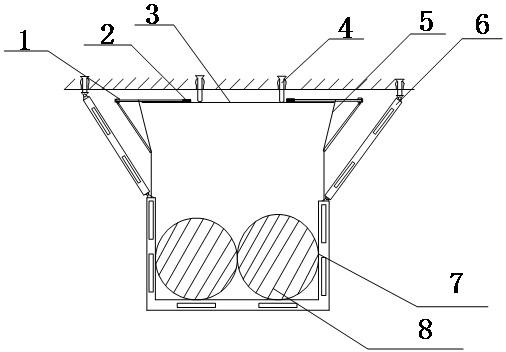

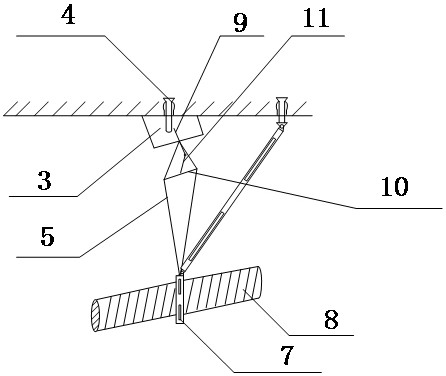

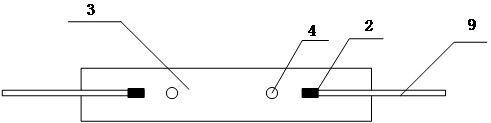

[0033] Please refer to Figure 1-7 , including a composite hanger, an adaptive anti-seismic hanger, including a composite hanger, characterized in that the composite hanger is provided with a steel wire rope structure supported by a steel frame, and two expansion screws (4 ), the steel plate (3) is fixed between the expansion screws (4), the first steel bracket (9) is connected to the plate (3) through the welding point (2), and the steel wire rope (5) is fixed on the first steel On the frame (9), below the first steel frame (9), the second steel frame (10) placed horizontally is fixed in the middle of the two steel wire ropes (5), and the second steel frame (10) placed horizontally passes through the L-shaped rope The clamp (13) is connected between the two steel wire ropes (5), and the third steel frame (11) is fixed at the end of the first steel frame (9) and the middle position of the second steel frame (10), and a balance is formed by three steel frames system, the U-sha...

Embodiment 2

[0035] Please refer to Figure 1-6 , including a comprehensive bracket, the first bracket (9) and the top steel plate (3) are fixed by welding points (2), the first bracket (9) and the third bracket (11) are connected by a steel sleeve (15), and the steel sleeve The sleeve is put on the first bracket (9), and the threaded end of the steel sleeve (16) is connected with the third bracket (11); the second bracket (10) is also connected with the third bracket (11) through the steel sleeve (15) , the steel sleeve sleeve is set on the second bracket (10), the threaded end of the steel sleeve (16) is connected with the third bracket (11); the second bracket (10) and the steel wire rope (5) pass through the L-shaped rope clamp (13) Connection, the L-shaped rope clamp (13) is connected with the second support (10) by thread (12).

[0036] The working principle of the present invention is as follows:

[0037] Under the action of the first, second and third brackets, the hanger uses th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com