Rapid pressure test device for air conditioner heat exchanger

A heat exchanger and pressure test technology, which is applied to measuring devices, instruments, and the use of stable tension/pressure to test the strength of materials, etc., can solve problems such as insufficient air pressure and increase the time for pressure test of heat exchangers, so as to reduce test pressure. The effect of pressing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] as attached figure 1 to attach Image 6 Shown:

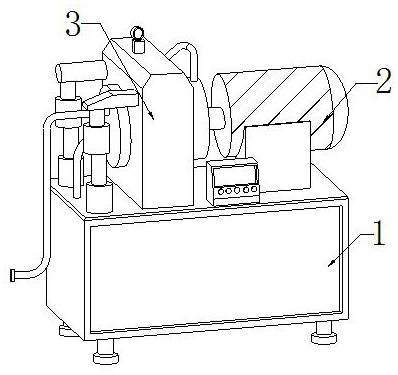

[0030] The invention provides a quick pressure test device for an air conditioner heat exchanger, the structure of which includes a body 1, a motor 2, and a pressure test table 3, the bottom of the motor 2 is fixed on the upper surface of the body 1 near the right end, and the pressure test table 3 is located on Motor 2 left.

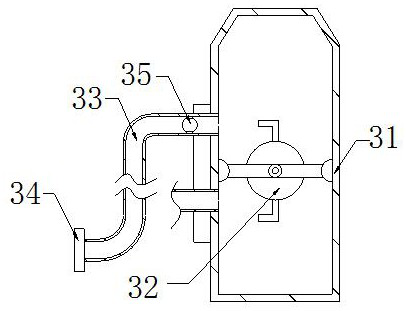

[0031] The pressure test table 3 includes a table body 31, an air pump 32, a pressure pipe 33, a connecting mechanism 34, and a blocking mechanism 35. The air pump 32 is installed in the middle of the table body 31, and the right end of the pressure pipe 33 is fixed in the middle of the table body 31. On the upper left side, the connecting mechanism 34 is sleeved outside the end of the pressure tube 33 , and the blocking mechanism 35 is set inside the pressure tube 33 near the right end.

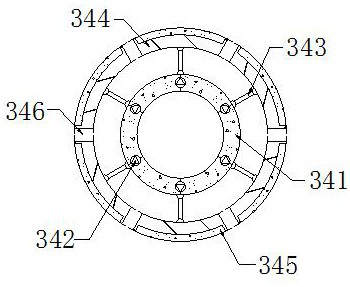

[0032] Wherein, the connection mechanism 34 includes a support ring 341, a magnetic block 342, a support ro...

Embodiment 2

[0039] as attached Figure 7 to attach Figure 9 Shown:

[0040] Wherein, the blocking mechanism 35 includes an expansion block 351, a clamping ball 352, an air outlet 353, a reset bar 354, a clamping groove 355, and a clamping block 356. The upper and lower surfaces of the clamping ball 352 are embedded and connected with the expansion block 351. The air outlet 353 runs through the surface of both sides of the card ball 352 to divide it into two parts. The upper and lower ends of the reset bar 354 are connected with the upper and lower inner walls of the air outlet 353 near the right end. The card groove 355 is recessed on the left side of the card ball 352 On the side upper surface, the top of the clamping block 356 is integrated with the lower surface on the left side of the clamping ball 352 above, and the clamping groove 355 is movably engaged with the clamping block 356, which can reduce the gap between the clamping balls 352 and can The airflow in the heat exchanger i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com