Engine speed adjusting rate adjusting method and device and storage medium

A technology of speed regulation and engine, applied in combustion engine, engine control, machine/engine, etc., can solve the problem of not being able to choose the speed regulation and speed of the engine, and meet the needs of freely selecting the speed regulation and speed of the engine Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

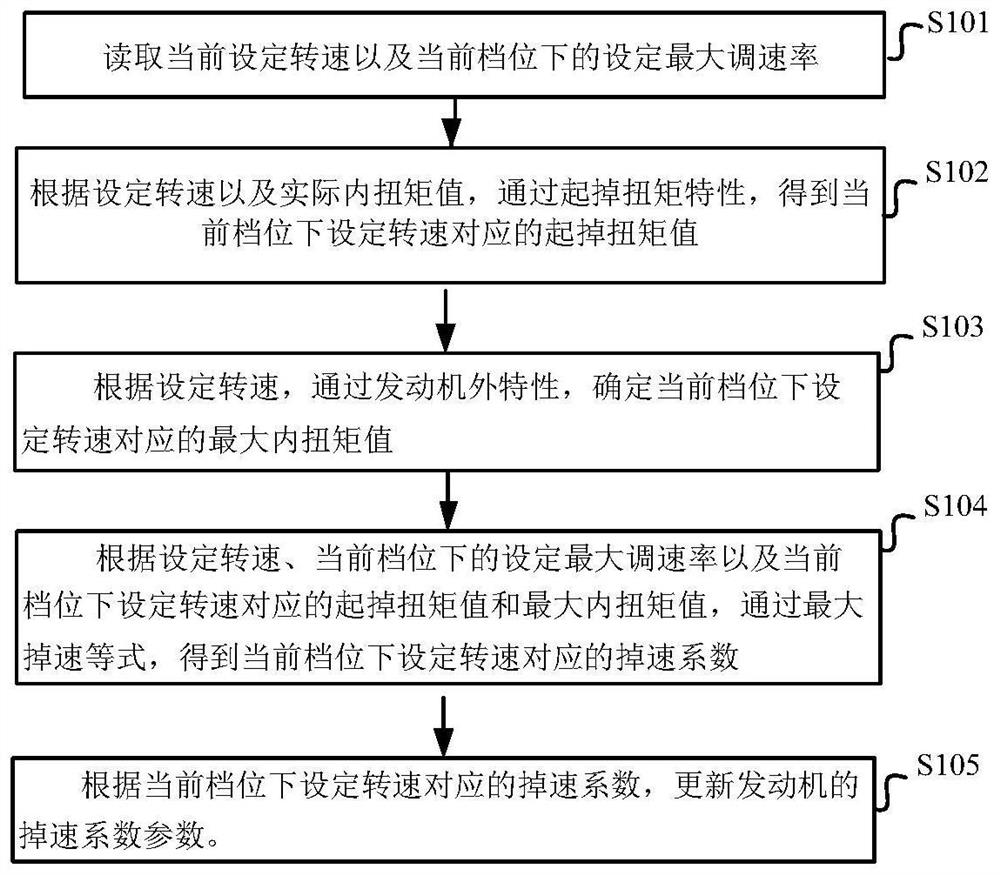

[0044] figure 1 A flow chart of the steps of an adaptive method for engine speed regulation adjustment according to an embodiment of the present application is shown in FIG.

[0045] Such as figure 1 As shown, the self-adaptive method for engine speed regulation in this embodiment specifically includes the following steps:

[0046] S101: Read the current set speed and the set maximum speed regulation under the current gear.

[0047] S102: Obtain the lift-off torque value corresponding to the set speed in the current gear through the lift-off torque characteristic according to the set speed and the actual internal torque value.

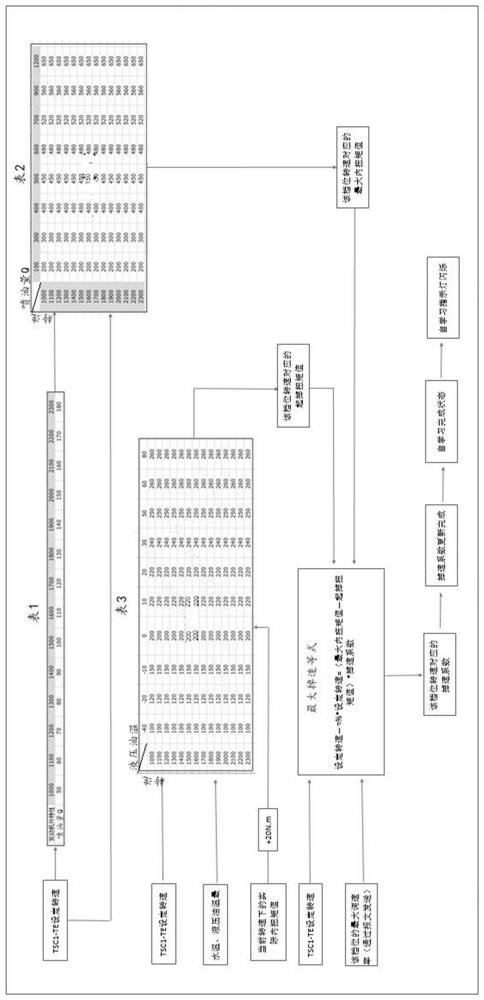

[0048] Specifically, the lift-off torque characteristic is the look-up table of lift-off torque obtained through the bench calibration test under different speeds and different hydraulic oil temperature characteristics, see figure 2 Table 3.

[0049] Wherein, in the lift-off torque lookup table, the lift-off torque corresponding to different rotat...

Embodiment 2

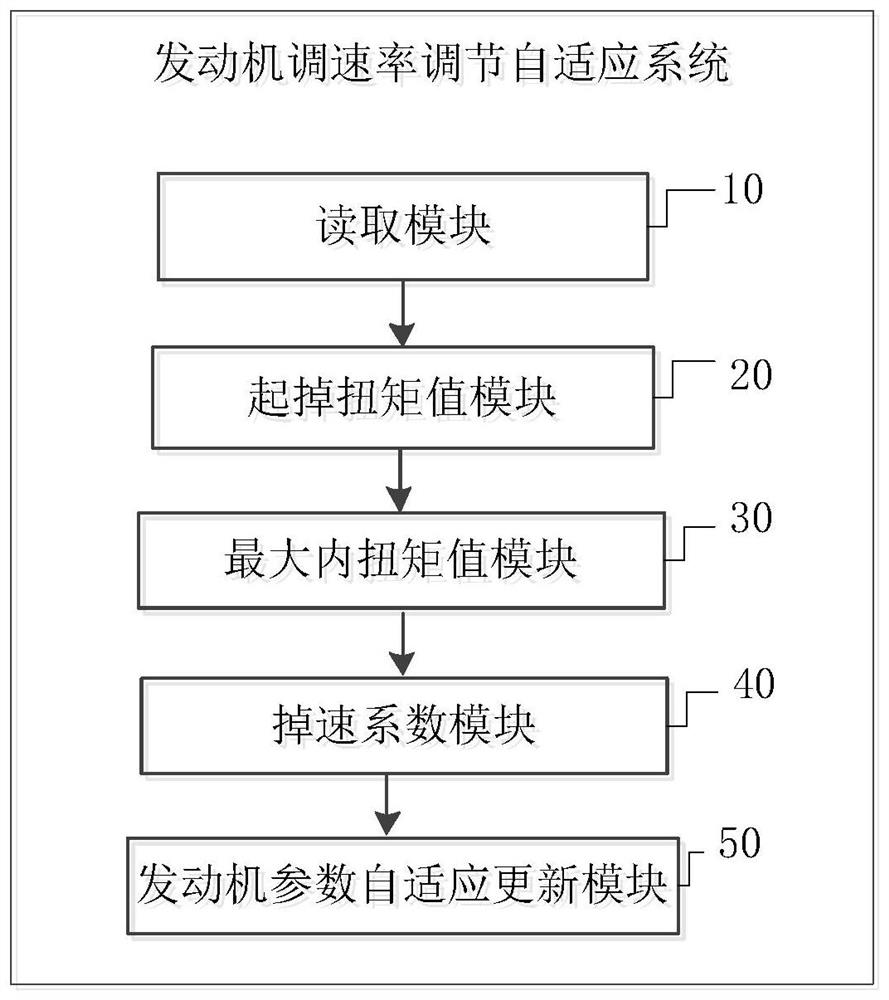

[0064] This embodiment provides an adaptive system for adjusting engine speed regulation. For details not disclosed in the adaptive system for adjusting engine speed regulation in this embodiment, please refer to the adaptive method for adjusting engine speed regulation in other embodiments. specific implementation content.

[0065] image 3 A schematic structural diagram of an adaptive system for adjusting engine speed regulation according to an embodiment of the present application is shown.

[0066] Such as image 3 As shown, the engine speed regulation adaptive system specifically includes:

[0067] Reading module 10: used to read the current set speed and the set maximum speed regulation under the current gear.

[0068] The lift-off torque value module 20: is used to obtain the lift-off torque value corresponding to the set speed in the current gear through the lift-off torque characteristic according to the set speed and the actual internal torque value.

[0069] Spe...

Embodiment 3

[0083] This embodiment provides an adaptive device for adjusting engine speed regulation. For the details not disclosed in the adaptive device for adjusting engine speed regulation in this embodiment, please refer to the adaptive method for adjusting engine speed regulation in other embodiments. Or the specific implementation content of the system.

[0084] Figure 4 A schematic diagram of an operation panel of an adaptive device for adjusting an engine speed regulation according to an embodiment of the present application is shown.

[0085] Such as Figure 4 As shown, the engine speed control adaptive device includes Figure 4 Operation control panel shown.

[0086] Specifically, the control panel is equipped with a four-hole connector, and communicates with the engine ECU through the OBD transfer harness. When the power supply of the equipment is normal, the power supply indicator on the control panel is always on; When the communication is normal, the communication indi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com