Multidirectional adjustable cast-in-place box girder integral sliding type side mold

A sliding and adjustable technology, which is applied in the fields of formwork/formwork/work frame, on-site preparation of building components, construction, etc., can solve the problem of the removal and erection of side formwork support with long construction period, high safety risk, and impact on box girder construction. progress, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

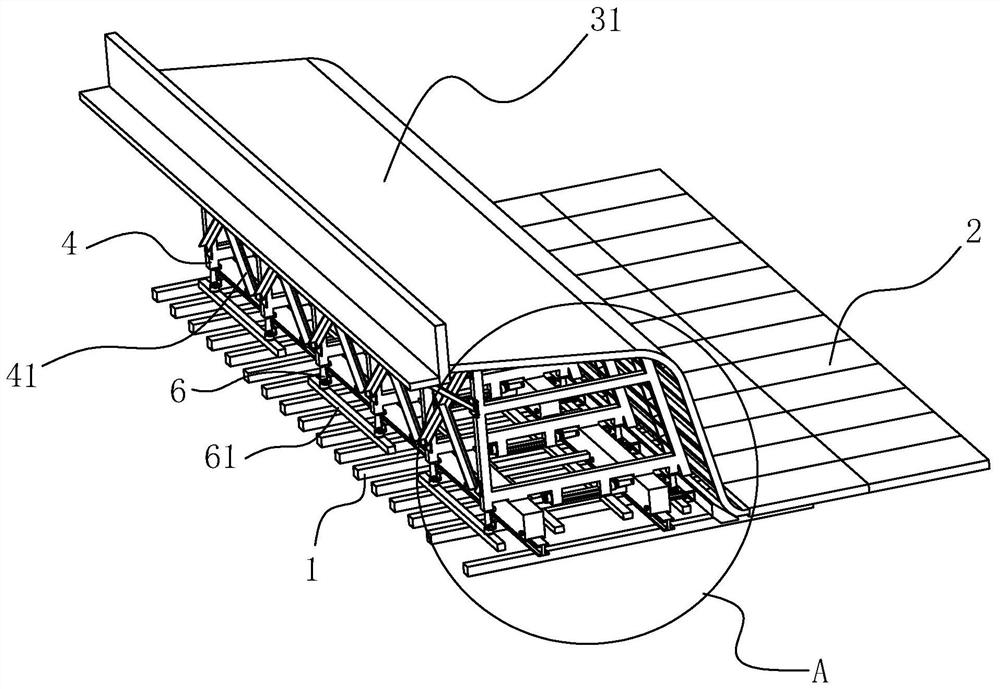

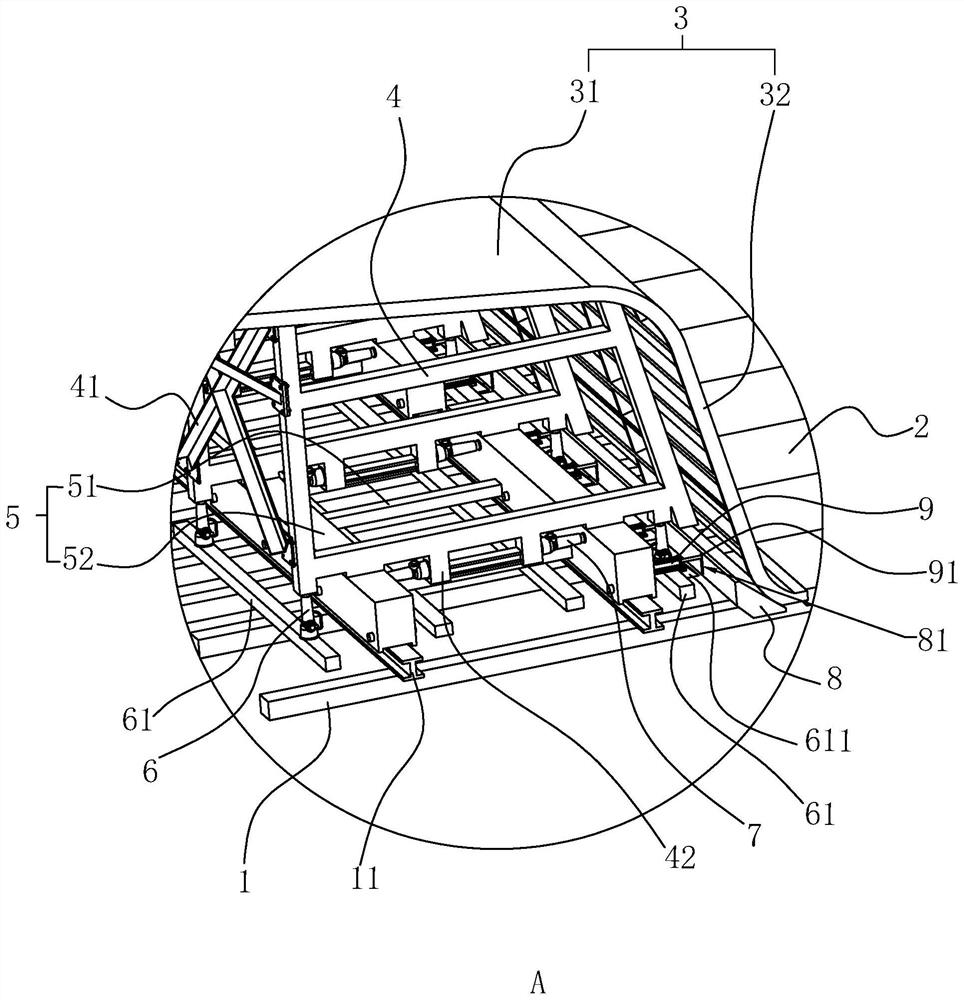

[0025] The following is attached Figure 1-2 The present invention is described in further detail.

[0026] The embodiment of the invention discloses a multi-directional adjustable cast-in-place box girder integrally sliding side form. A multi-directional adjustable cast-in-place box girder integrated sliding side form includes guide rails, a formwork trolley 5, a formwork support and a side formwork 3. Bottom form 2 is vertically laid on the upper end surface of distribution beam 1, and the formwork support is fixed on the outside of side formwork 3, so that the lower end edge of side formwork 3 is connected with one side of bottom formwork 2. The guide rail is located at one side of the bottom mold 2, and the guide rail extends longitudinally. The formwork trolley 5 slides along the length direction of the guide rail, and the formwork support is erected on the upper surface of the trolley. After the box girder of the upper hole is poured and the concrete has the strength t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com