Self-adaptive microcapsule for packaging dust suppressant calcium alginate, preparation method of self-adaptive microcapsule and bio-based dust suppression material

A calcium alginate, bio-based technology, used in chemical instruments and methods, other chemical processes, etc., can solve problems such as corrosiveness, unfavorable cost, and toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

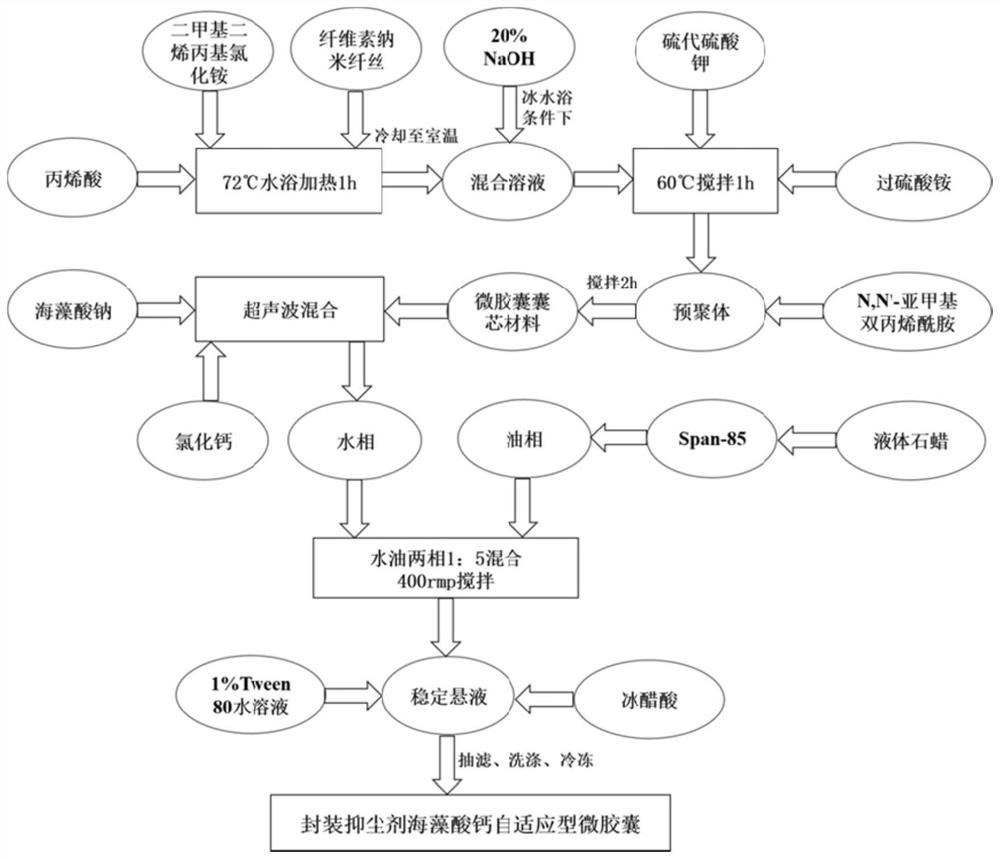

Method used

Image

Examples

Embodiment 1

[0053] Cellulose nanofibrils are extracted from peanut shells. The extraction method of extracting cellulose nanofibrils from peanut shells is:

[0054] Accurately weigh 10 g of dried peanut shell powder, place it in a Soxhlet extractor, use benzene-ethanol solution (2:1 by volume) to soak at 90°C for 6 hours, remove the extract, and dry it. The dried samples were soaked in sodium chlorite solution at 75°C for 1 hour under acidic conditions (pH=4-5, adjusted by glacial acetic acid), and repeated five times in succession to remove lignin to obtain cellulose sample S1 . Prepare 300ml of 5wt% potassium hydroxide solution, soak the sample in it at room temperature for 24 hours, remove hemicellulose, and obtain treated cellulose sample S2. Finally, in order to further remove residual lignin, the sodium chlorite solution (what is the mass concentration) was soaked repeatedly for 2-3 times to obtain purified cellulose sample S3. In order to make peanut shell cellulose nanometer, i...

Embodiment 2

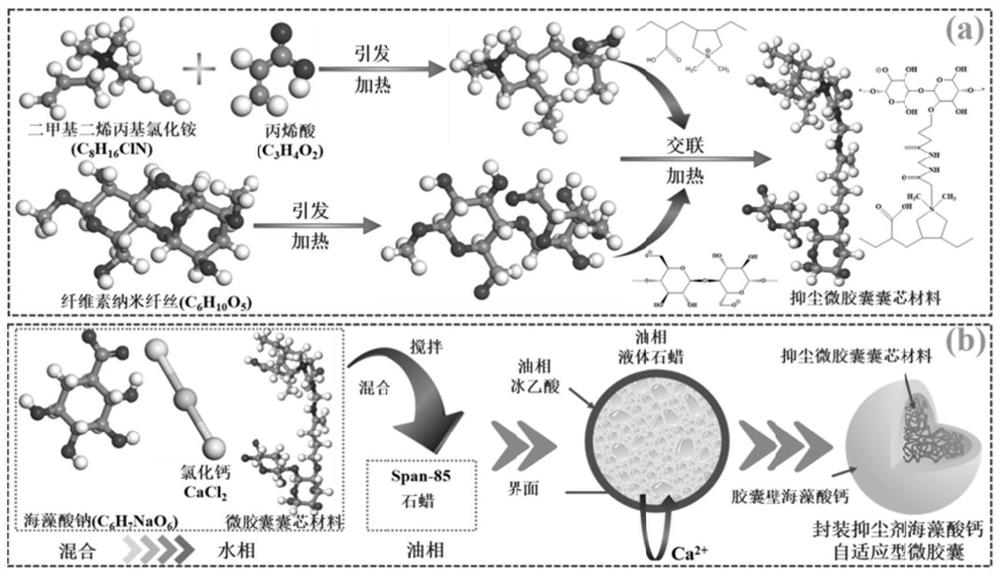

[0057] The core material of the dust-suppressing microcapsules consists of 1% dimethyl diallyl ammonium chloride (DMDAAC for short), 1% cellulose nanofibrils, 5% acrylic acid (AA for short), and 0.125% acrylic acid according to the mass fraction. The agent is composed of ammonium persulfate and potassium thiosulfate, 0.09% of cross-linking agent N,N'-methylenebisacrylamide, alkaline pH regulator sodium hydroxide, and the balance of water. Dimethyldiallyl ammonium chloride: cellulose nanofibrils: acrylic acid 1:1:5. Preparation of dust-suppressing microcapsule core material,

[0058] Accurately weigh dimethyl diallyl ammonium chloride, cellulose nanofibrils and acrylic acid in a container, add deionized water and stir until they dissolve.

[0059] Prepare sodium hydroxide solution, put it into the container under the condition of ice-water bath to neutralize acrylic acid to neutral, then add the initiator to it, stir and mix well, react at 55-60°C for 1 hour, and finally slowl...

Embodiment 3

[0067] The self-adaptive microcapsules of calcium alginate, an encapsulated dust suppressant, are made by mixing oil phase materials and water phase materials at a volume ratio of 1:5.

[0068] The water phase material is composed of 3% dust-suppressing microcapsule capsule core material, 12% sodium alginate, 7% nano-scale calcium chloride and water as the balance according to the mass percentage.

[0069] The dust-suppressing microcapsule capsule core material consists of 2.5% dimethyl diallyl ammonium chloride, 1% cellulose nanofibrils, 10% acrylic acid, 0.25% initiator ammonium persulfate, 0.18 % of cross-linking agent N, N'-methylenebisacrylamide, alkaline pH regulator sodium hydroxide, and the balance of water. The ratio of dimethyl diallyl ammonium chloride: cellulose nanofibrils: acrylic acid is 2.5:1:10, the crosslinking agent is N,N'-methylenebisacrylamide, and the initiator is potassium thiosulfate.

[0070] The oil phase is a liquid paraffin solution of Span-85 wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com