A plastic pipe bending process

A technology of plastic pipe and process, applied in the field of plastic pipe processing, can solve problems such as heat waste, pipe stretching deformation, etc., and achieve the effects of improving energy saving and environmental protection performance, reducing consumption, and improving work quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

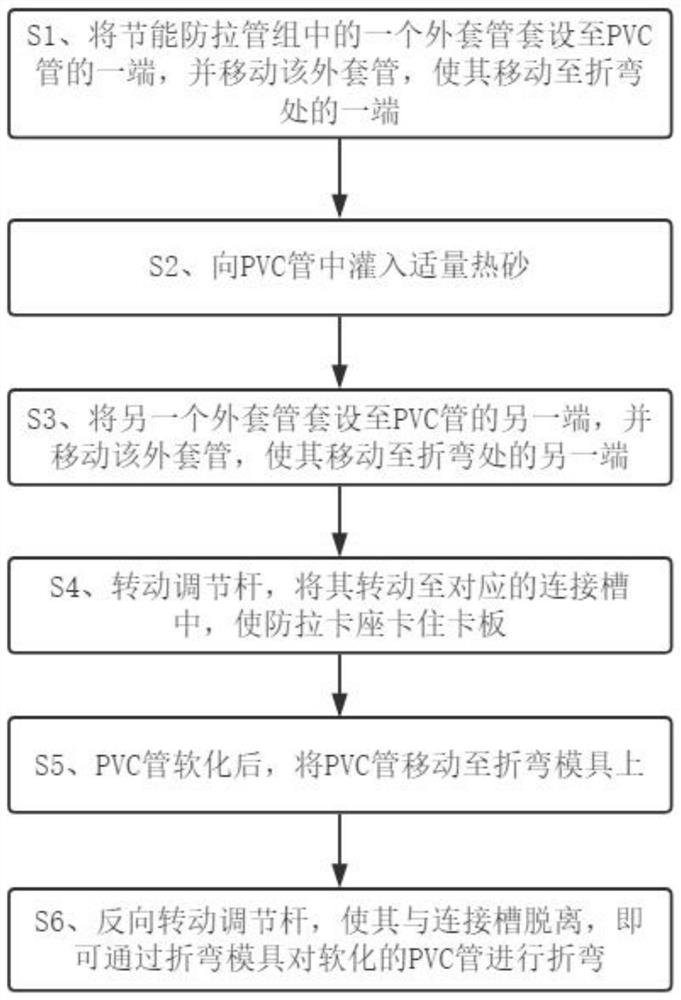

[0051] see Figure 1-10 , a plastic pipe bending process, comprising the following steps:

[0052] S1. Sleeve an outer sleeve 101 in the energy-saving anti-pull tube group to one end of the PVC pipe, and move the outer sleeve 101 to one end of the bend;

[0053] S2. Pour an appropriate amount of hot sand into the PVC pipe;

[0054] S3. Sleeve another outer sleeve 101 to the other end of the PVC pipe, and move the outer sleeve 101 to the other end of the bend;

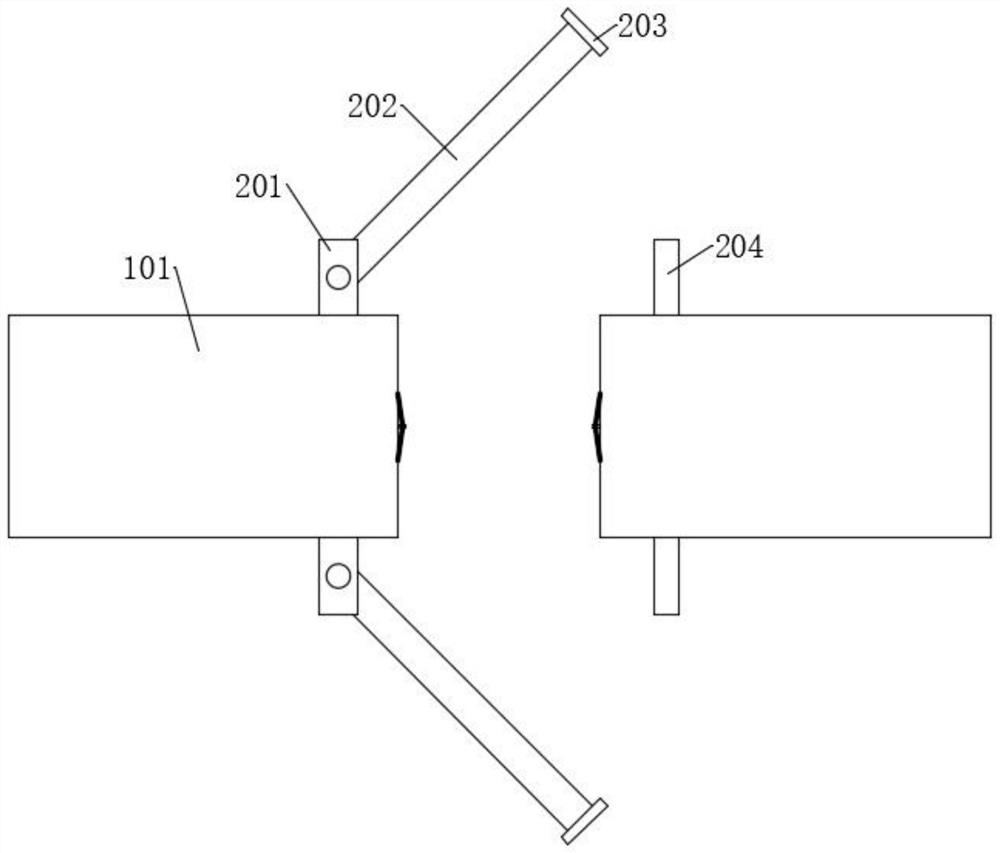

[0055] S4. Rotate the adjusting rod 202 to the corresponding connecting groove 205, so that the anti-pull holder 204 clamps the clamping plate 203;

[0056] S5. After the PVC pipe is softened, move the PVC pipe to the bending mold;

[0057] S6. Rotate the adjusting rod 202 in reverse to disengage from the connecting groove 205, and then the softened PVC pipe can be bent by the bending mold.

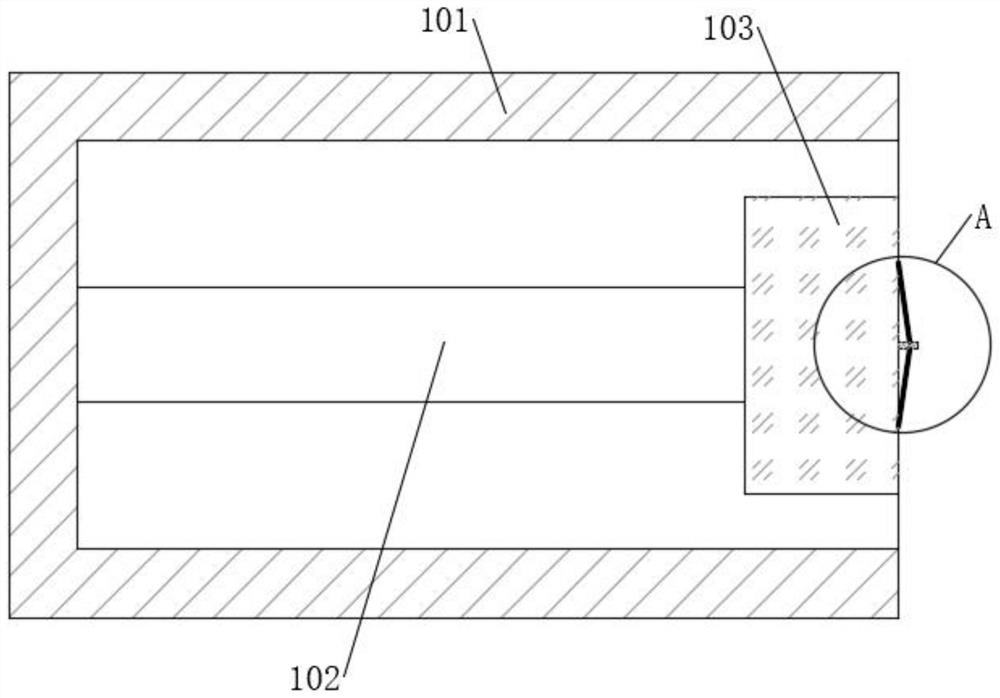

[0058] see Figure 2-3 , the energy-saving anti-pull pipe group includes two outer casings 101, the inner wall of the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com