Special protective cover for turning and milling composite machine tool

A compound machine tool, turning and milling technology, applied in maintenance and safety accessories, metal processing machinery parts, metal processing equipment, etc., can solve the problems of time-consuming and laborious production needs, inconvenient movement or adjustment, operator injury, etc., to save time in operation The effect of labor saving, simple and efficient installation and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

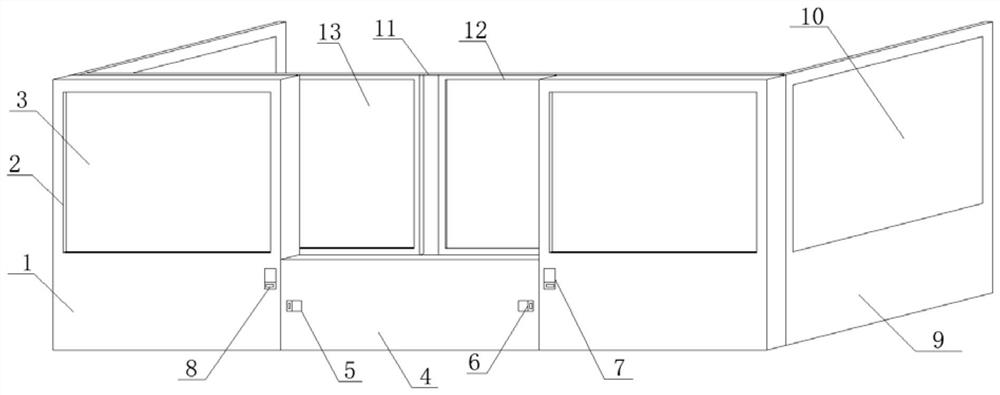

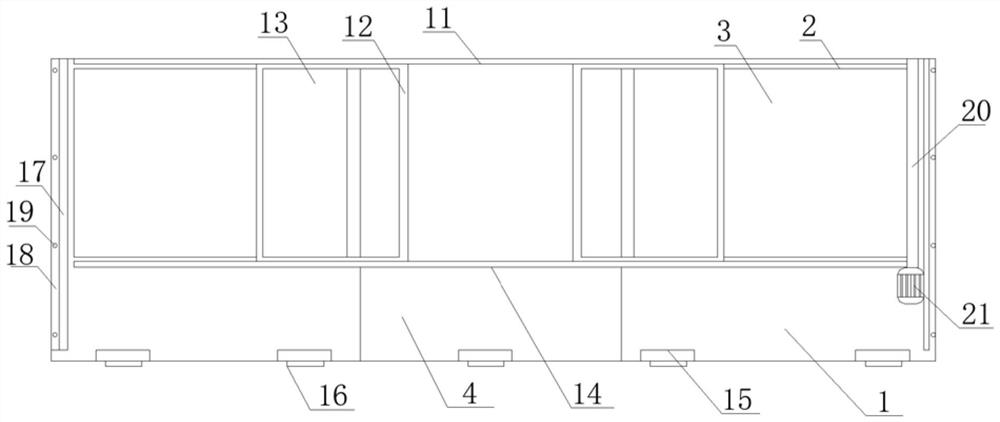

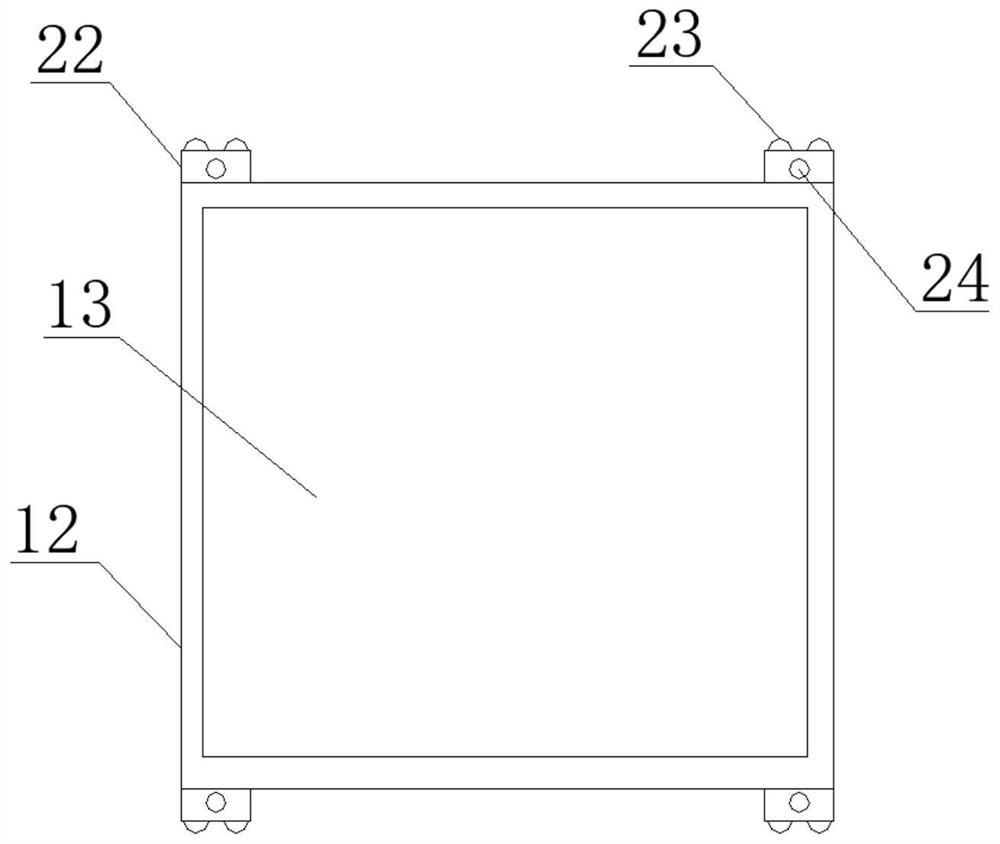

[0028] see Figure 1-2 , in an embodiment of the present invention, a special shield for turning and milling compound machine tools, including a main support plate 1, an observation window 2 is provided on the side of the main support plate 1, and a transparent plate 3 is horizontally clamped on the inner side of the observation window 2 , the number of main support plates 1 is two, and the two main support plates 1 are arranged parallel to each other vertically and symmetrically, the specifications and sizes of the two main support plates 1 are kept consistent, and the observation window 2 is set horizontally on the main support One side of the plate 1 is close to the top surface, and the transparent plate 3 is made of a heat-resistant transparent material. The main support plate 1 is horizontally connected to the connecting bottom plate 4, and one side of the connecting bottom plate 4 is horizontally symmetrical. Toggle the groove 5, the connecting bottom plate 4 is set hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com