Insulating part press-in equipment for motor production

A technology for insulating parts and equipment, which is applied to the field of press-fitting equipment for insulating parts used in motor production, can solve the problems of workpiece damage, low fault tolerance, waste of motor production parts, etc., to prevent excessive downforce, save production costs, and adjust Simple and convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

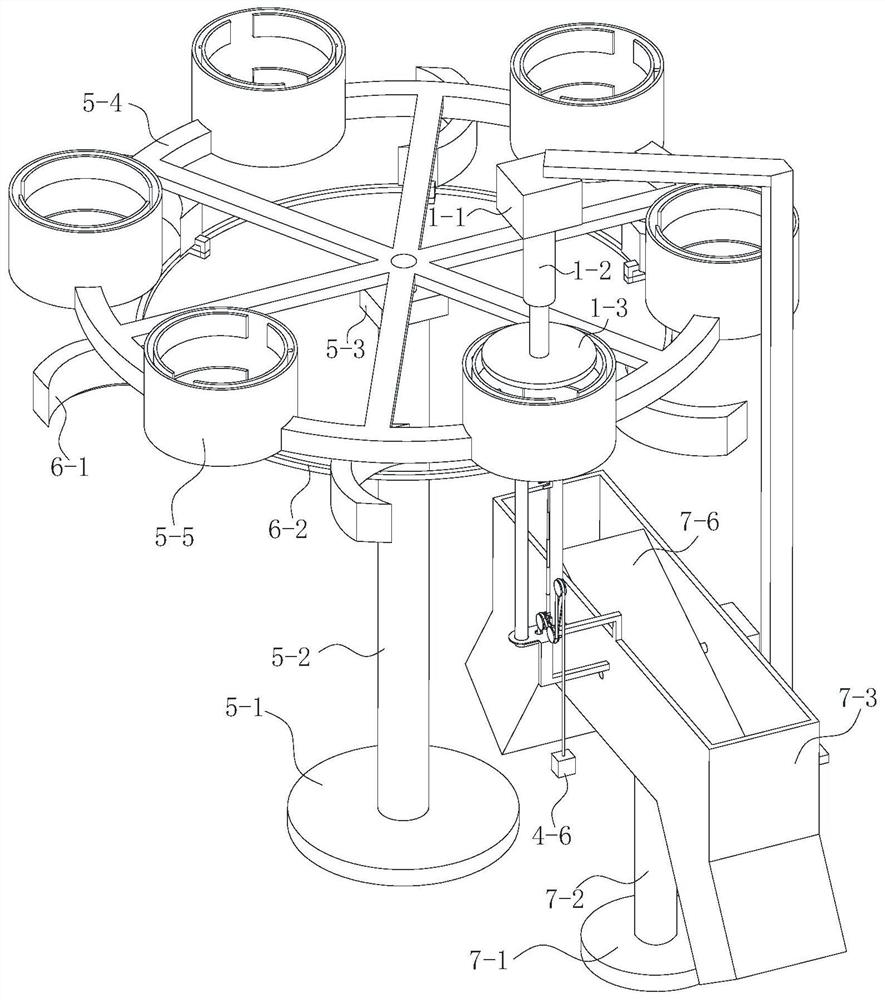

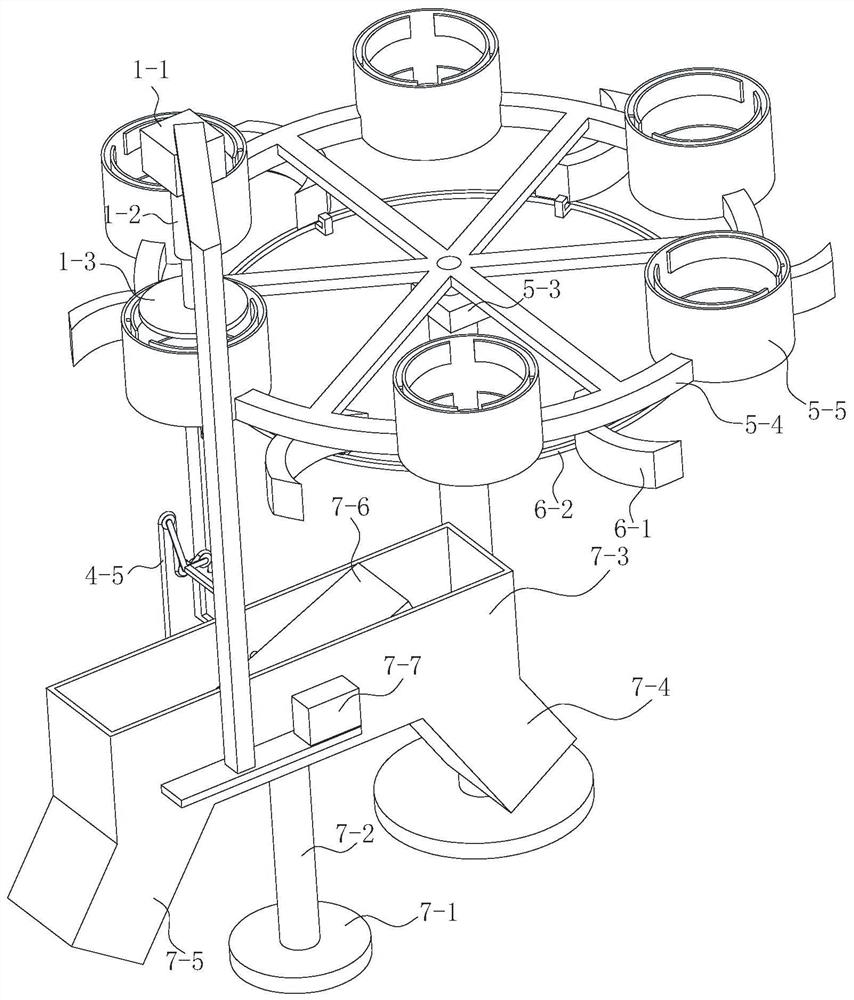

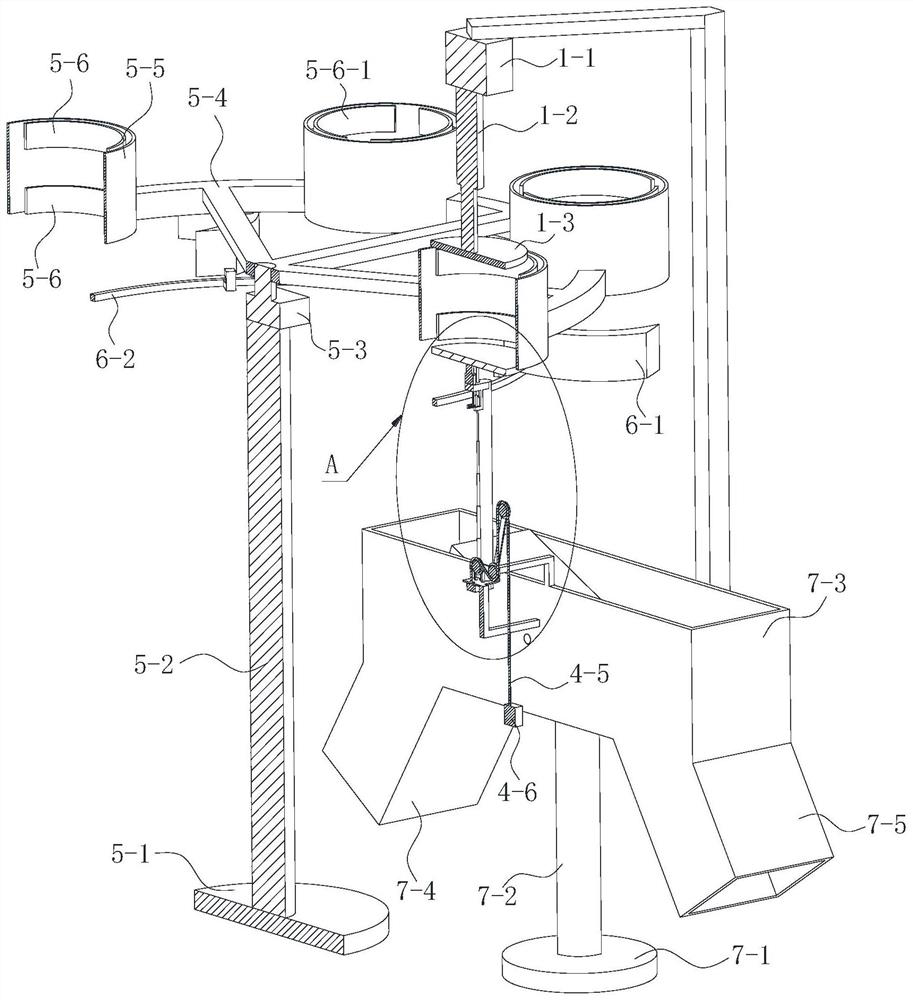

[0031] see Figure 1-10 , the present invention provides a technical solution: a press-in equipment for insulating parts for motor production, including an extrusion mechanism and a tray mechanism; the extrusion mechanism is installed directly above the tray mechanism, and the extrusion mechanism is used for uniform speed Press down the insulator and the motor stator on the tray mechanism, the tray mechanism can be displaced vertically and can provide a constant support force for the insulator and the motor stator, so that when the insulator cannot be pressed into the motor stator, it will not be damaged by the extrusion mechanism The forcible extrusion of the motor leads to damage to the insulation or the motor stator.

[0032] When working, put the aligned insulator and the motor stator between the extrusion mechanism and the tray mechanism, and then press the extrusion mechanism down at a constant speed to apply a downward pressure on the insulator, so that the insulator is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com