Telescopic motor capable of accurately controlling extension length of main shaft and application thereof

A telescopic motor and extension length technology, applied in the direction of controlling mechanical energy, electrical components, electromechanical devices, etc., can solve the problems of inability to meet the precise movement or positioning of long-stroke and large-load equipment, limited bearing capacity, and low telescopic accuracy, and achieve extended The working life and reliability of the equipment, the long telescopic stroke, and the effect of improving the uniformity of the force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

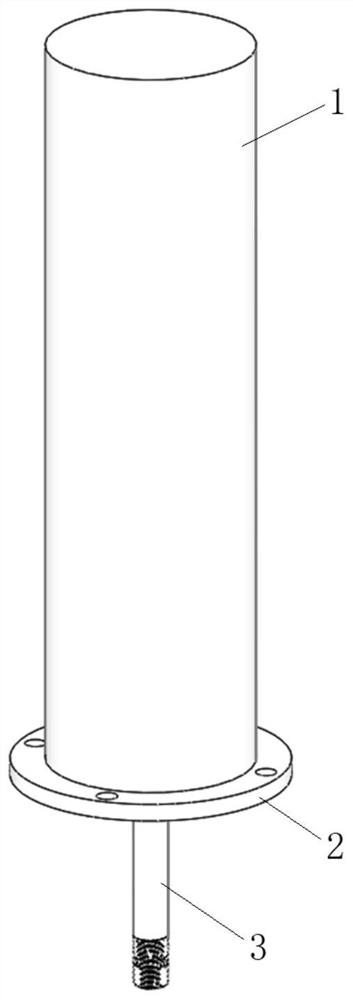

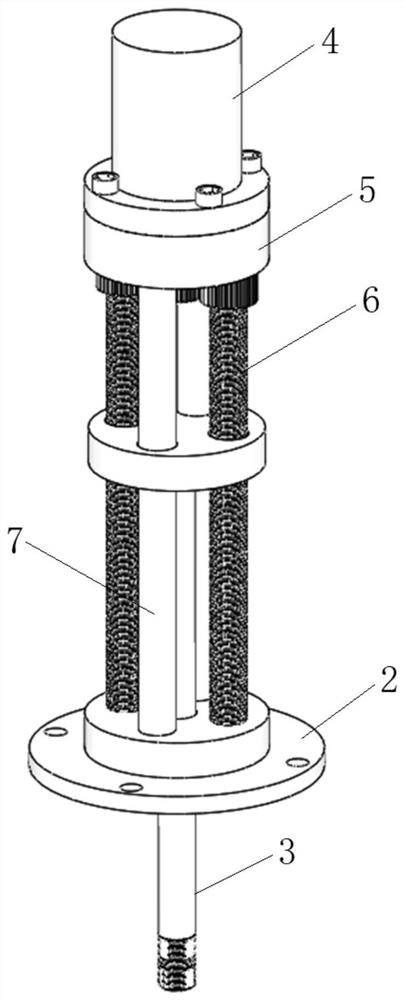

[0039] Such as Figure 1-9 As shown, this embodiment provides a telescopic motor with precise control of the extension length of the main shaft, including a casing 1 and a motor 4 placed in the casing, a top plate 5, a chassis 2, a lead screw 6, a main shaft 3 and a piston 16;

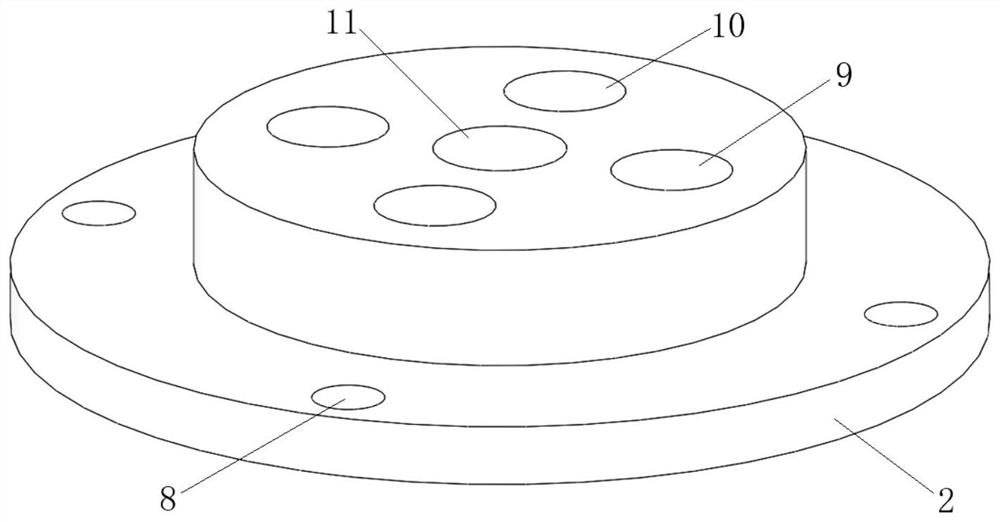

[0040] The motor 4 is fixedly connected to the top plate 5, the lead screw 6 runs through the piston 16 and is threadedly connected with the piston 16, the upper and lower ends of the lead screw 6 are respectively connected to the top plate 5 and the chassis 2, and the output shaft of the motor 4 is connected to the upper end of the lead screw by transmission. The top of the main shaft 3 is fixedly connected with the bottom surface of the piston 16 , and the bottom end of the main shaft 3 extends out of the casing 1 after penetrating the chassis 2 . The center of the chassis 2 is provided with a through hole 11 through which the main shaft 3 protrudes.

[0041] Specifically, the entire casing 1 is cyl...

Embodiment 2

[0051] A working method of a telescopic motor that precisely controls the extension length of the main shaft, using the telescopic motor provided in Embodiment 1, includes the following steps:

[0052] 1) Control the servo motor to start the operation through the external controller (the servo motor is connected to the external controller circuit), and the servo motor drives the driving gear to rotate through the reduction mechanism;

[0053] 2) The driving gear meshes with the driven gear, thereby driving the driven gear and the lead screw 6 to rotate synchronously;

[0054] 3) The lead screw 6 rotates, so that the piston 16 is subjected to an upward or downward force, and moves upward or downward along the path limited by the guide post 7, and finally drives the main shaft 3 to move up and down.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com