Method and device for determining operation and maintenance process of equipment, electronic equipment and storage medium

A determination method, operation and maintenance technology, applied in the direction of instruments, data processing applications, resources, etc., can solve the problems of low operation and maintenance requirements, low operation and maintenance efficiency, low work efficiency, long processing time, etc., saving processing time and manpower, simplifying Workflow, the effect of improving operation and maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

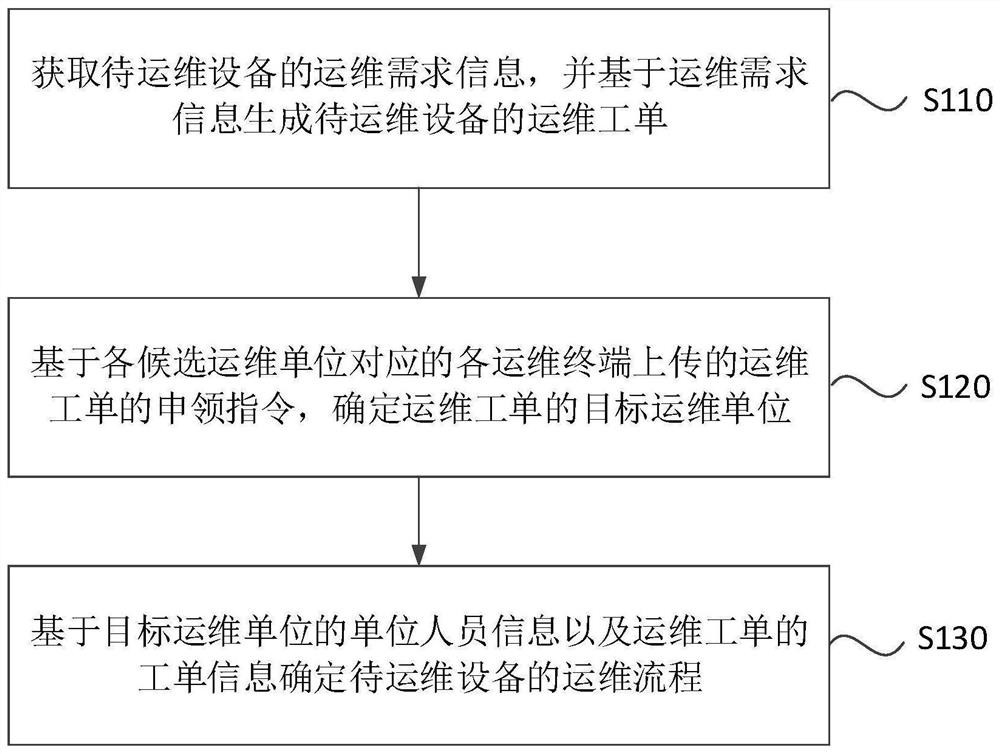

[0040] figure 1 It is a flow chart of a method for determining the operation and maintenance process of equipment provided by Embodiment 1 of the present invention. This embodiment is applicable to the situation where the equipment to be operated and maintained is maintained. Specifically, it is more suitable for Apply for instructions, determine the target operation and maintenance unit and process information, and maintain the equipment to be operated and maintained based on the process information. The method can be executed by the apparatus for determining the operation and maintenance process of the equipment, and the apparatus can be realized by means of software and / or hardware.

[0041] Before introducing the technical solution of this embodiment, an exemplary introduction is given to the application scenarios of this embodiment. Of course, the following application scenarios are only optional application scenarios of the technical solution of this embodiment. The tech...

Embodiment 2

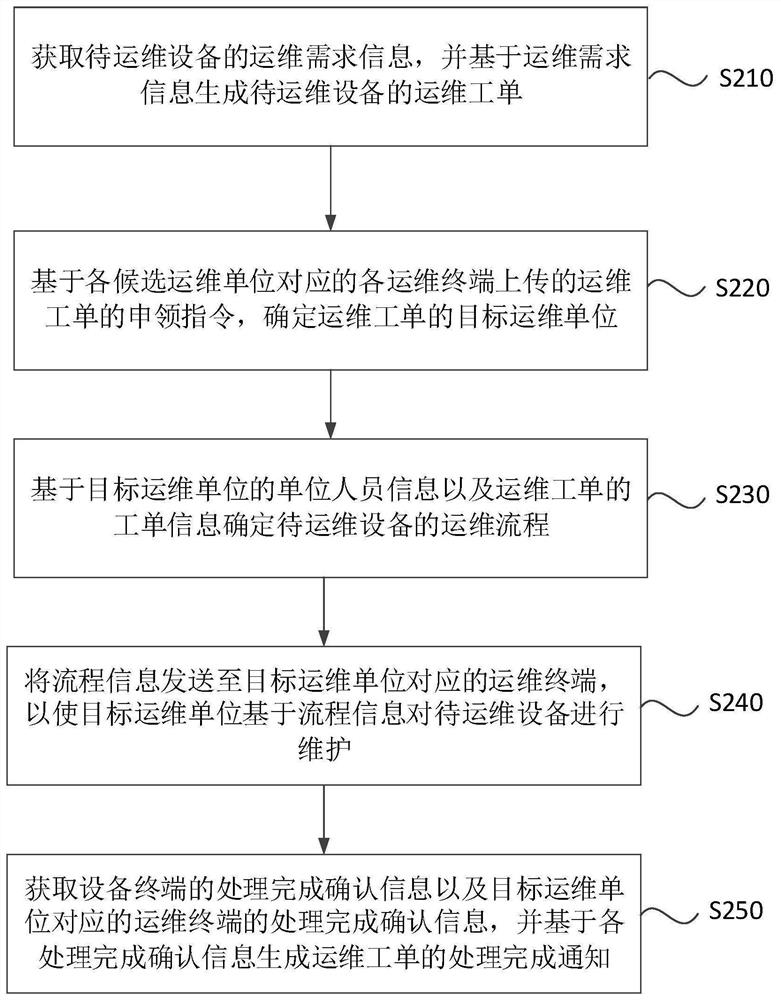

[0062] figure 2 It is a flow chart of a method for determining the operation and maintenance process of equipment provided by Embodiment 2 of the present invention. On the basis of the above-mentioned embodiments, this embodiment, in the step "Based on the unit personnel information of the target operation and maintenance unit and the operation and maintenance work order After the work order information determines the operation and maintenance process of the equipment to be operated and maintained", the step "send the process information to the operation and maintenance terminal corresponding to the target operation and maintenance unit is added, so that the target operation and maintenance unit can maintain the equipment to be operated and maintained based on the process information " and the step "obtain the processing completion confirmation information of the equipment terminal and the processing completion confirmation information of the operation and maintenance terminal...

Embodiment 3

[0076] image 3 It is a schematic structural diagram of the device for determining the operation and maintenance process of the equipment provided by Embodiment 3 of the present invention. This embodiment is applicable to the situation where the equipment to be operated and maintained is maintained, and specifically, it is more suitable for applying for an operation and maintenance work order Instructions, determine the target operation and maintenance unit and process information, and maintain the equipment to be operated and maintained based on the process information. The specific structure of the device for determining the operation and maintenance process of the device includes: an operation and maintenance work order generation module 310, a target operation and maintenance unit determination module 320, and an operation and maintenance process determination module 330; wherein:

[0077] The operation and maintenance work order generation module 310 is configured to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com