High-altitude cantilever structure formwork support and upper protection system construction method

A technology of structural formwork and protection system, applied in the direction of building structure support, building structure support, formwork/formwork/working frame, etc., can solve the problems of undisclosed safety protection system, large amount of steel, etc., to achieve safe and reliable project quality, The effect of quality assurance and accelerated construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

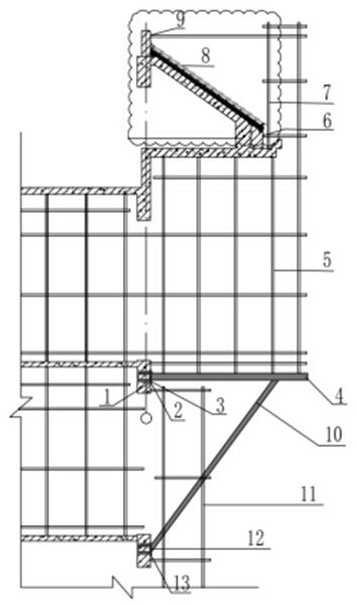

[0027] The high-altitude cantilever structure formwork support and the construction method of the upper protection system of the present invention comprise the following steps:

[0028] a. Position, install embedded parts and leave connecting bolts in advance along with the main structure (on the second floor and the next floor) during construction.

[0029] figure 1 It is a structural schematic diagram of the high-altitude cantilevered structure formwork support and the upper protection system according to the embodiment of the present invention. The pre-embedded part of the double-tensioned steel plate is used, and it is factory-processed according to the width of the beam by connecting four opposite-tensioned bars (the embedded part includes the connecting bolts as a whole). Accurate positioning is carried out according to the special construction plan, and the review is strengthened to ensure that the position of the pre-embedded part is accurate. .

[0030] b. Install t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com