Pressure piece with an optimised thickness ratio, and plate-link chain comprising a pressure piece

A technology of pressure parts and thickness ratio, which is applied in the field of transmission system, can solve the problems of heavy load, low efficiency and wear of plate link chain, and the running radius cannot meet high requirements, and achieve the effect of high strength and load reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

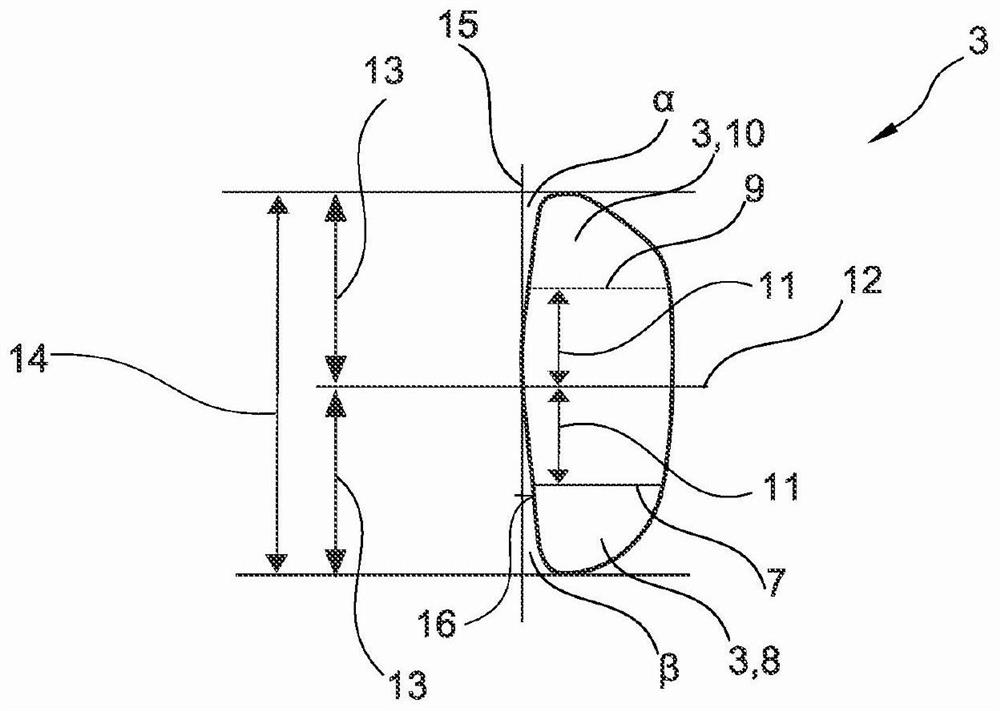

[0018] The drawings are merely schematic in nature and are used only for the understanding of the invention. The same elements are provided with the same reference numerals.

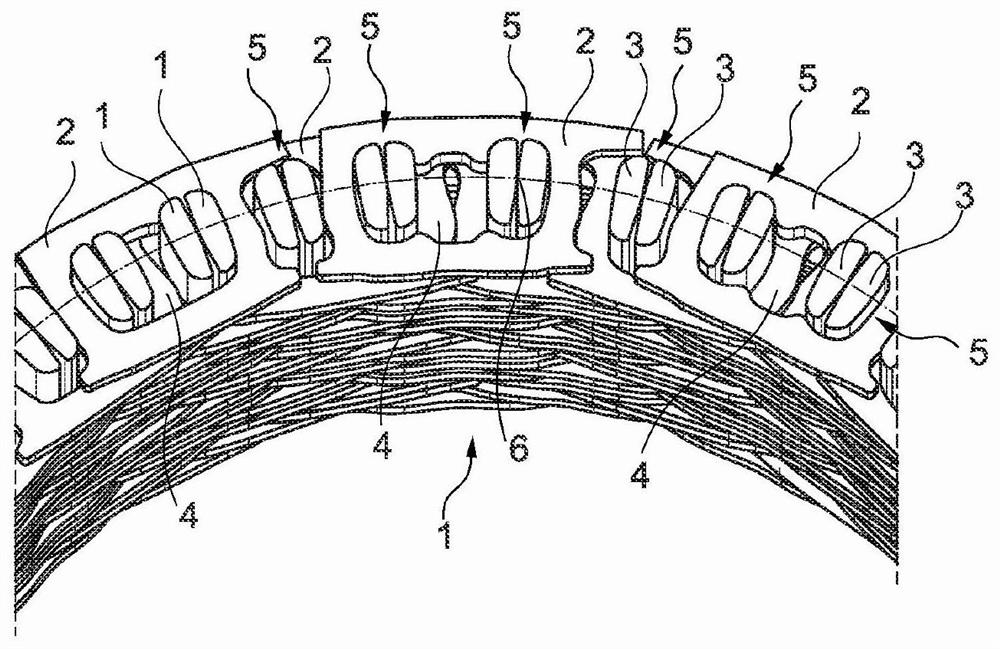

[0019] figure 1 A part of an exemplary general embodiment of a leaf link chain 1 for a drive train of a motor vehicle is shown. The plate link chain 1 is used in particular for continuously variable transmissions (CVT transmissions). For example, the plate link chain 1 is used as a traction device of a variator to connect two pairs of conical pulleys of the variator to each other. The plate link chain 1 has a large number of links 2 which are referred to below as links 2 . The link 2 is arranged parallel to the running direction of the plate link chain 1 . The links 2 are arranged in a plurality of rows which are arranged next to each other with respect to the running direction of the plate link chain 1 . The links 2 are articulated to each other via a rocker pressure piece 3 , referred to below as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com