A battery structure and a transport vehicle equipped with the battery

A truck and battery technology, applied in the field of trucks, can solve the problems of inconvenience, taking a long time to fully charge, and taking a certain amount of time to return to the working position, so as to achieve the effect of being easy to charge, satisfying the battery life, and reducing unusability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

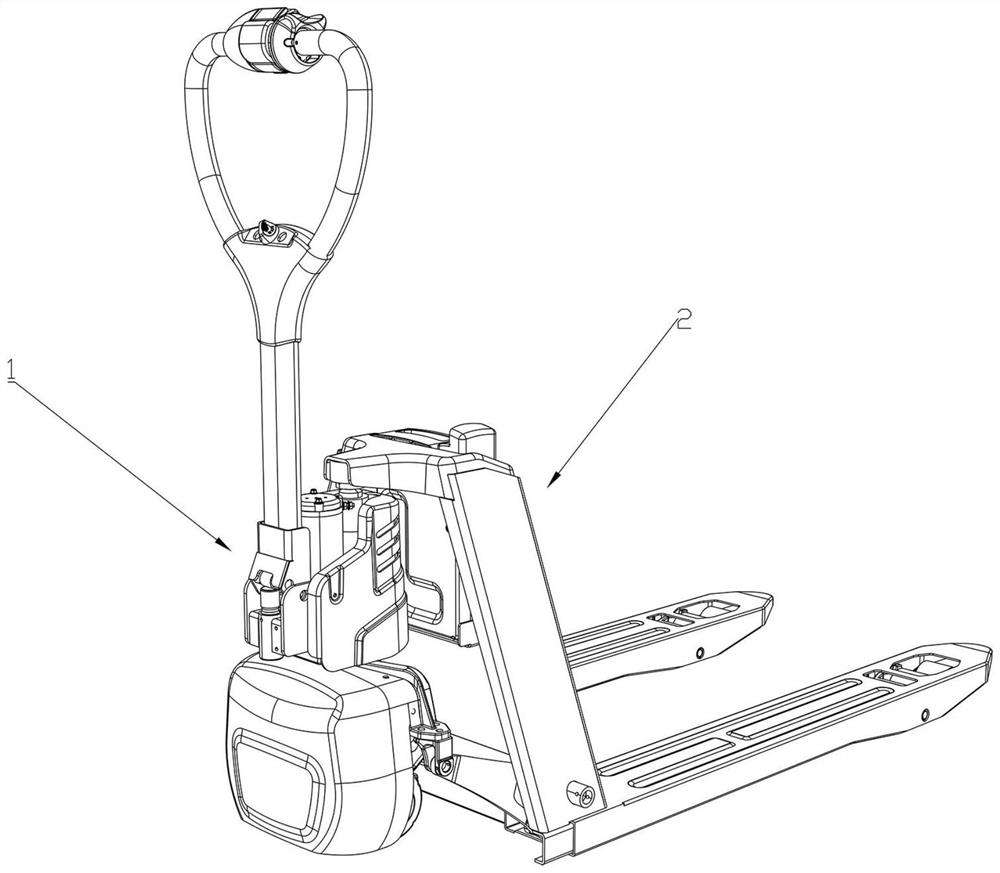

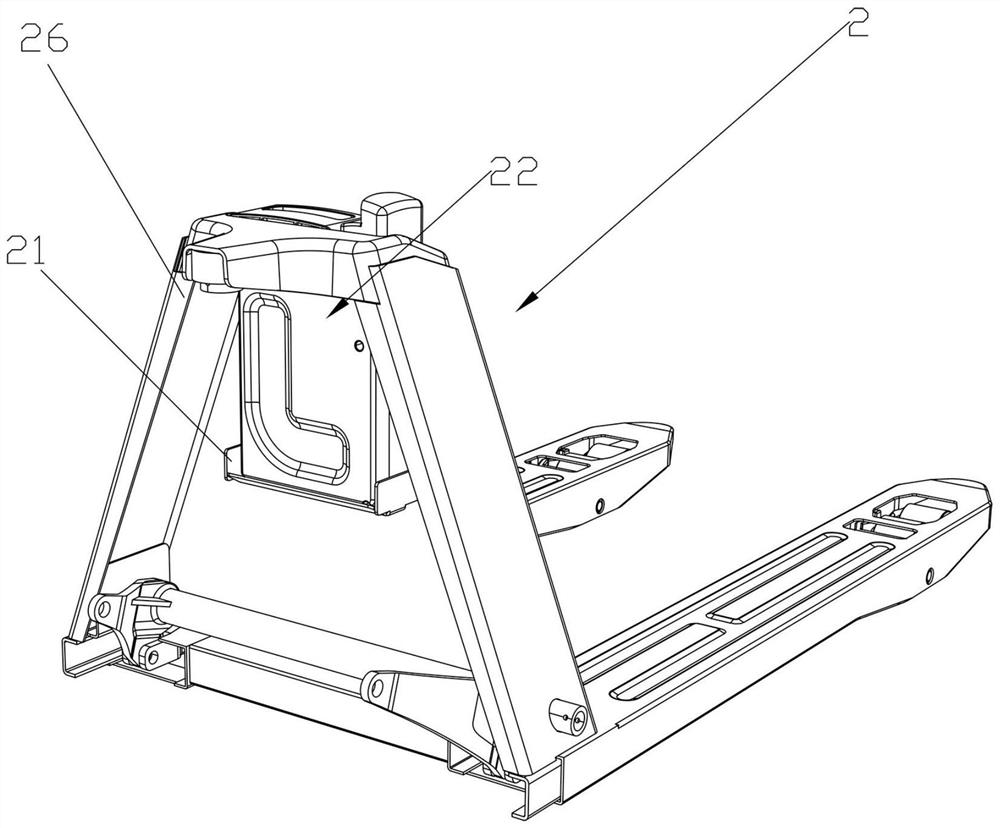

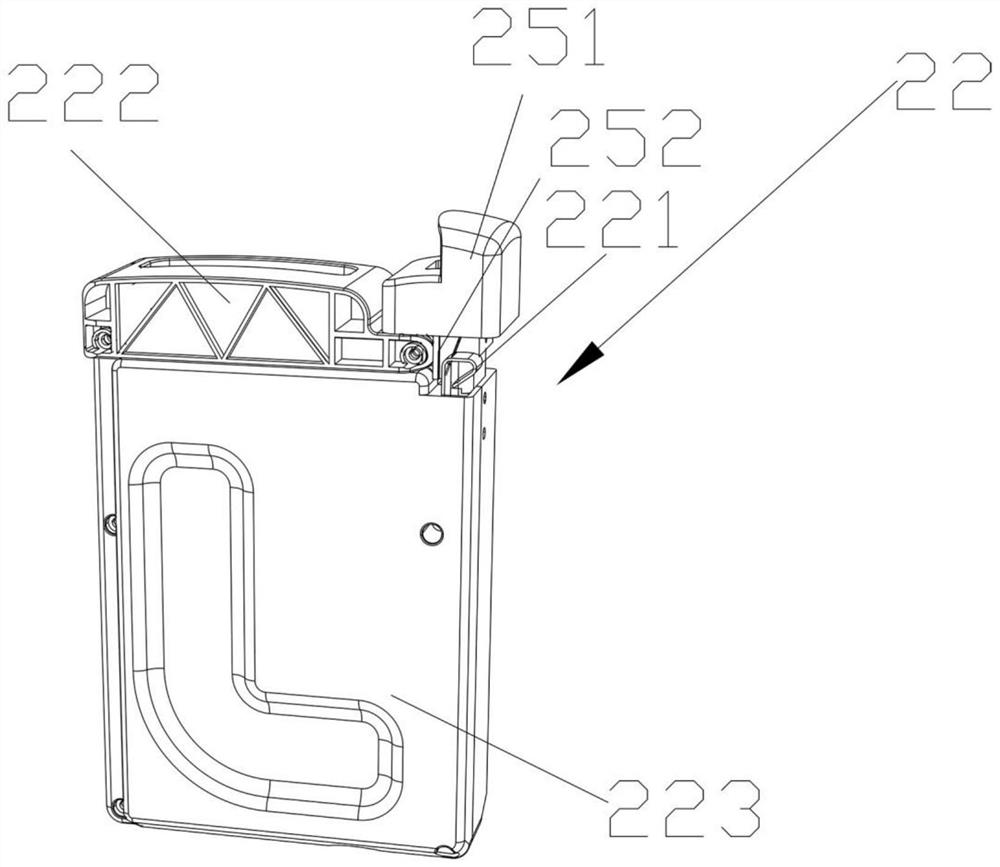

[0042] With reference to the accompanying drawings of the description of the present invention Figure 1 to Figure 24 As shown, according to a preferred embodiment of the present invention, a truck includes a front frame 2 and a rear frame 1, the rear frame 1 can be disassembled on the front frame 2, and the front frame The frame 2 includes a frame body 26, at least one battery structure 22 installed on the longitudinal inner wall of the frame body 26, and a link wheel assembly 23 arranged at the lateral bottom of the frame body 26; the battery structure 22 includes a battery body 223, a plug assembly 25 and a handle 222; the handle 222 is detachably connected to the top or side of the battery main body 223; the plug assembly 25 includes at least one plug end, and the plug end can be inserted into The battery main body 223 enables the plug-in socket assembly to be energized by plugging in, a mounting guide rail 21 is provided on the longitudinal inner wall of the frame body 26...

Embodiment 2

[0052] This embodiment provides an assembling method, which is used for assembling the truck in the first embodiment. The assembling method includes a first assembly line 8 for assembling the front frame 2 and a first assembly line 8 for assembling the rear frame 1 Second assembly line, the first assembly line 8 includes a loading station 81, an assembly station 82, a welding station 83, a paint repair station 84, a turning station 85 and a packing station that are transported by conveyor belts in sequence; the loading station The station 81 is provided with a hanging chain for transporting and making the forming frame body 26, a camera, and a six-axis manipulator for grabbing the frame body 26 from the hanging chain and placing it on the conveyor belt; the assembly station 82 is provided with a positioning laser And the cylinder, the welding station 83 is provided with a welding machine, the paint repair station 84 is provided with a paint repair spray gun, the turnover statio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com