Electric wheel with energy recovery and multi-direction vibration reduction functions

An energy recovery and multi-directional technology, which is applied in the field of automobile wheel vibration reduction, can solve the problems of high sealing requirements of hydraulic shock absorbers, failure of hydraulic shock absorbers to reduce vibration, and small damping working range, etc. Impact, easy assembly and maintenance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing.

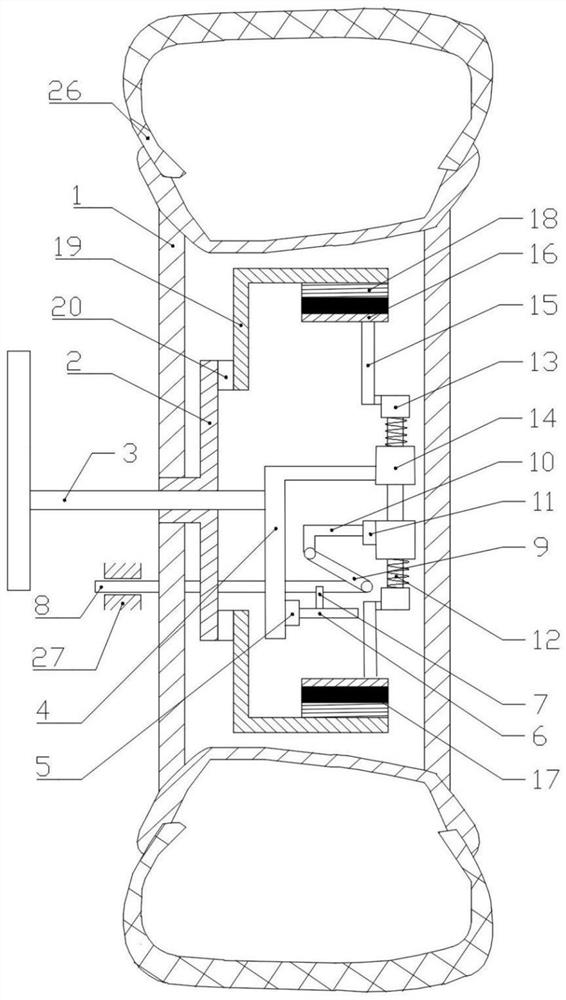

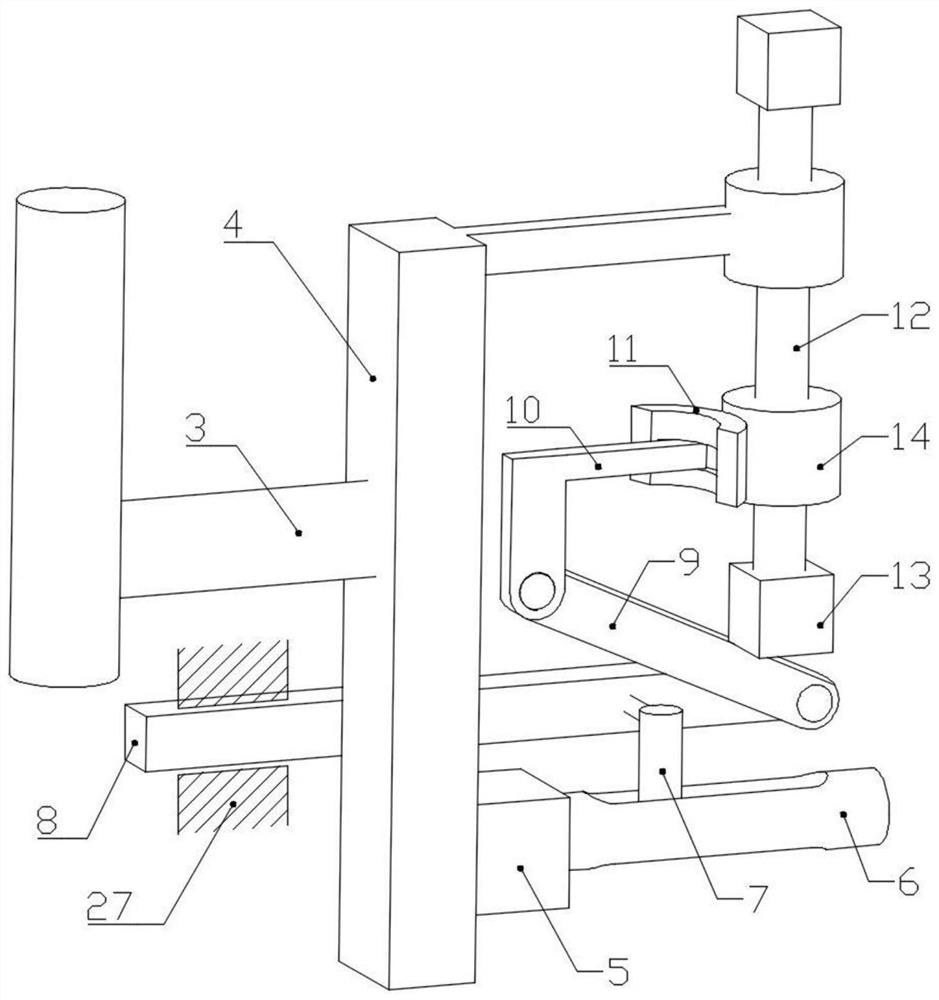

[0025] Such as figure 1 , 2 . As shown in 3, an electric wheel with a multi-directional vibration damping system includes a vertical vibration transmission module, a vibration synchronization suppression module, a vibration transmission assembly, an in-wheel motor module and a wheel module. The vertical vibration transmission module is installed on the vehicle body, which includes the axle 3 and the first connecting block 4 . The first connecting block 4 is welded and fixed on the outer end of the axle 3 . The wheel module comprises a spoke 1 , a rotating disc 2 , an axle 3 and a tire 26 . The rotating disk 2 is supported on the axle 3 through bearings. Wheel spoke 1 is fixed with rotating disk 2. The tire 26 is sleeved on the outer side of the spoke 1 .

[0026] The in-wheel motor module includes a stator 16 , a stator core 17 , a stator winding 18 , a rotor 19 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com