Clutch capable of realizing rotary control over degree of tightness

A clutch and loosening technology, which is applied in the direction of clutches, one-way clutches, fastening objects, etc., can solve the problems of complex structure and unstable structure of the lacing device, and achieve the effects of simple structure, convenient assembly, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

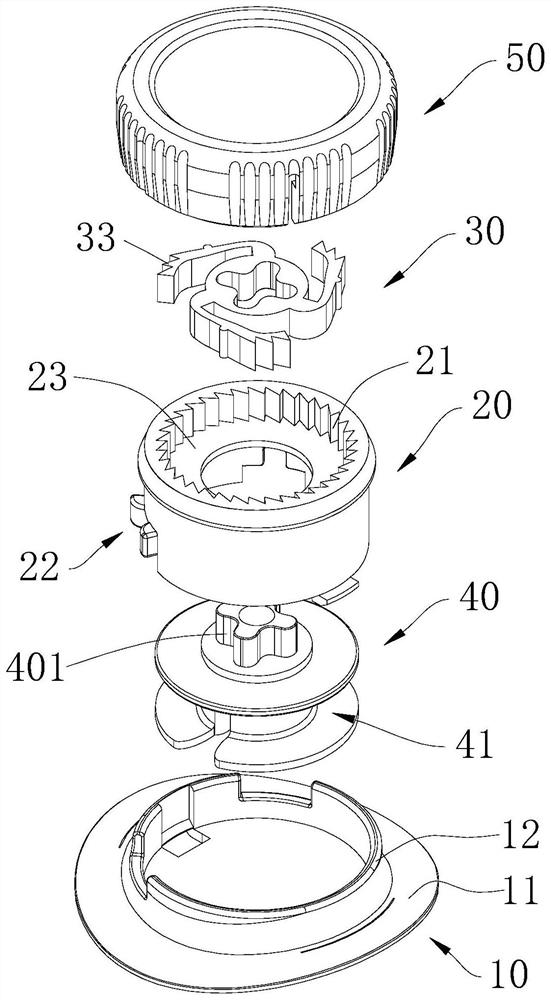

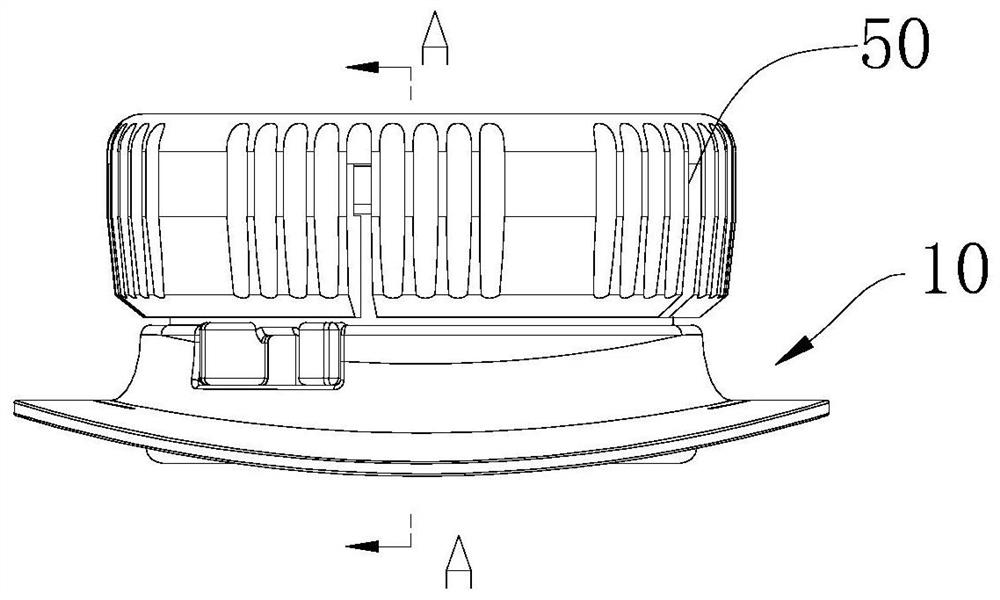

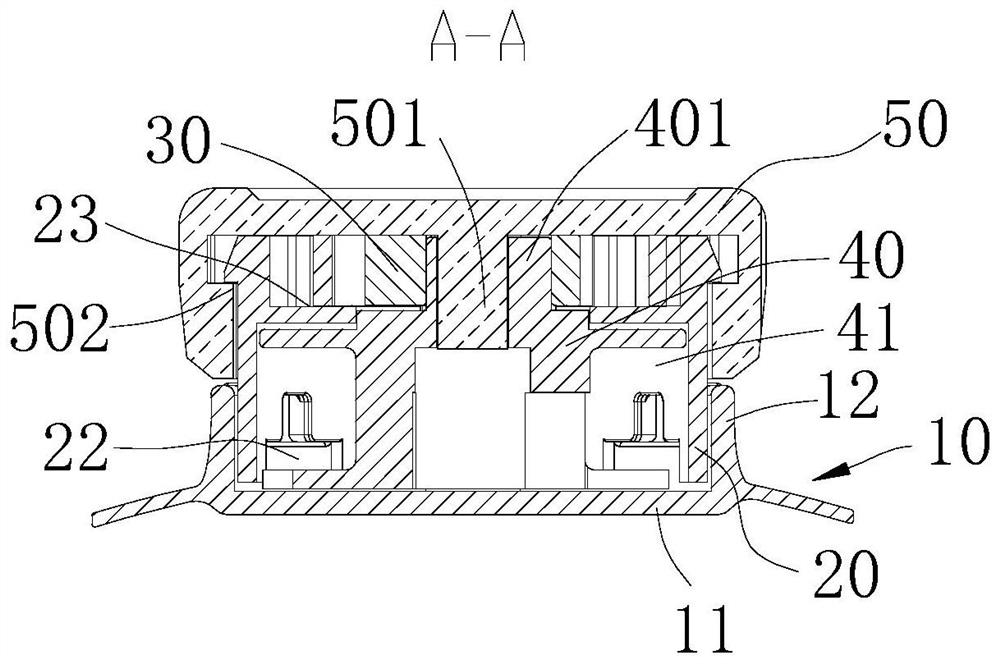

[0048] Please refer to Figure 1 to Figure 3 , In the embodiment provided by the present invention, the rotation control loose clutch includes a clutch fixed chassis 10 , a clutch body 20 , a clutch pawl 30 , a clutch output shaft 40 and a knob 50 .

[0049] Specifically, the clutch fixed chassis 10 includes a bottom plate 11 and a cylindrical portion 12 arranged on the bottom plate 11, the bottom plate 11 and the cylindrical portion 12 form a half-open space, and the diameter of the clutch main body 20 is slightly smaller than the diameter of the cylindrical portion 12, for The lower end of the clutch main body 20 is placed in the semi-open space and is stuck on the clutch fixed chassis 10 to ensure the fixed connection between the clutch main body 20 and the clutch fixed chassis 10 . The clutch fixing base 10 is arranged at the bottom of the rotating control elastic clutch, and the periphery of the base plate 11 is used for sewing on wearable objects such as shoes. Preferab...

no. 2 example

[0067] see Figure 12 and Figure 13 The difference between this embodiment and the previous embodiment is that: each unlocking portion 52 is an arc-shaped groove formed in a depression on the lower surface of the knob 50; each elastic arm 32 has a protrusion 321 correspondingly extending toward the arc-shaped groove The protrusion 321 is embedded in the arc-shaped groove and slides in the arc-shaped groove, and the arc-shaped groove radiates from a position close to the center of the knob 50 to the outer circumference, that is, between any part of the arc-shaped groove and the gear teeth 21 The distances are different, so as to guide the elastic arm 32 to deform, so that the pawl 33 and the gear teeth 21 form an engaged state or a disengaged state.

[0068] Please combine Figure 14 , in this embodiment, the lower surface of the knob 50 is provided with a driving part 51, and the driving part 51 can be a block of any shape. Since the driving part 51 is fixed on the lower su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com