Centrifugal heat dissipation fan

A cooling fan, centrifugal technology, applied in the field of centrifugal cooling fans, can solve problems such as difficult to control air flow, insufficient wind pressure, large blade air gap, etc., and achieve the effect of improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Reference will now be made in detail to the exemplary embodiments of the present invention, examples of which are illustrated in the accompanying drawings. Wherever possible, the same reference numbers will be used in the drawings and description to refer to the same or like parts.

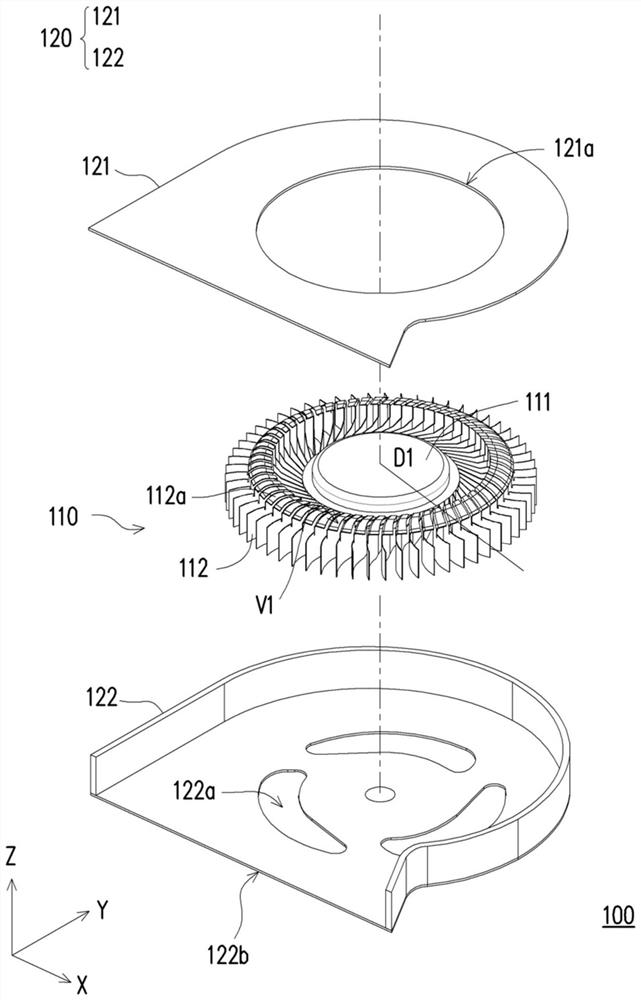

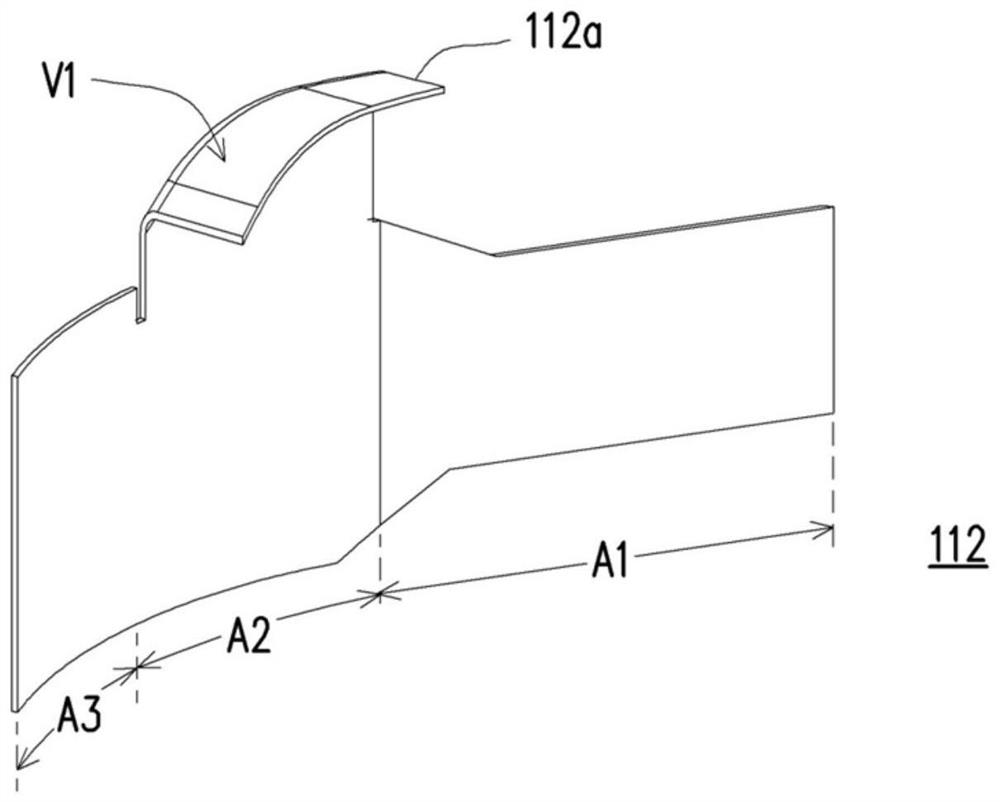

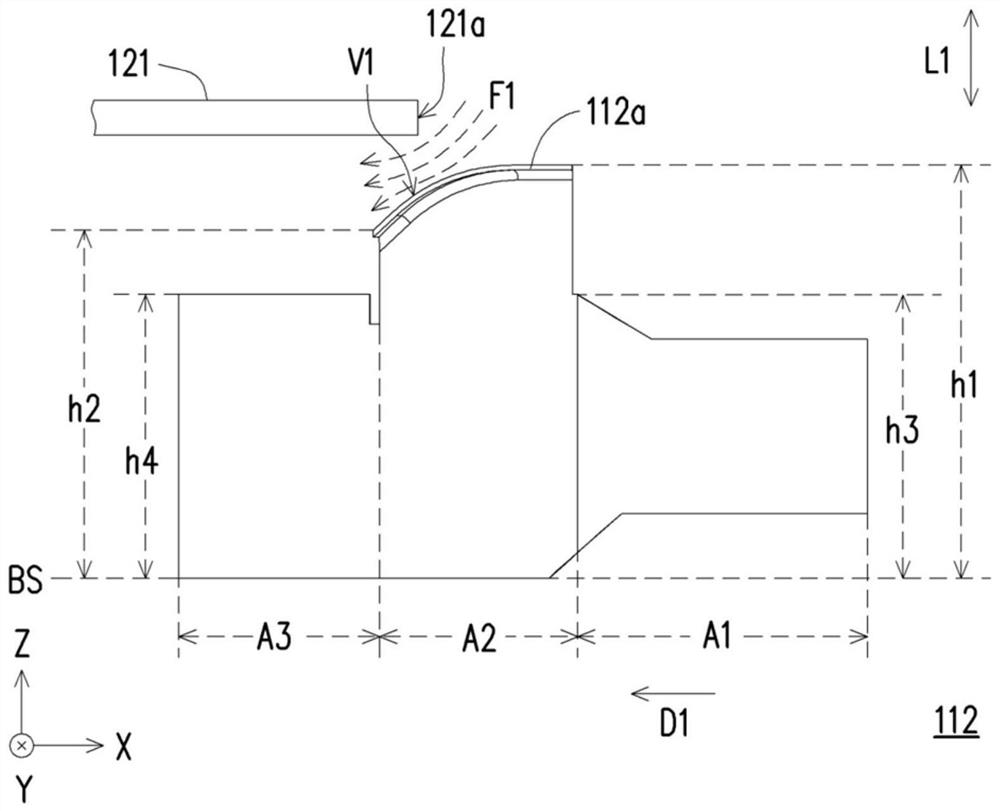

[0018] figure 1 It is an exploded view of a centrifugal cooling fan according to an embodiment of the present invention. Figure 2A yes figure 1 perspective view of the blades of a centrifugal cooling fan. Figure 2B yes figure 1 A partial side view of a centrifugal cooling fan. Cartesian coordinates X-Y-Z are also provided here to facilitate component description. Please also refer to figure 1 and Figure 2A , Figure 2B , in this embodiment, the centrifugal cooling fan 100 includes a housing 120 and an impeller 110 . The casing 120 is composed of a base 122 and a top plate 121, and the casing 120 has air inlets 122a, 121a. Here, the air inlets 121a and 122a of the casing 120 bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com