A device and construction method for solidifying river silt in situ

A technology of river silt and construction method, applied in chemical instruments and methods, fixed/solidified sludge treatment, electrochemical sludge treatment, etc. Ideal and other problems, to achieve the effect of uniform sludge consolidation, simple and fast construction, and weight reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

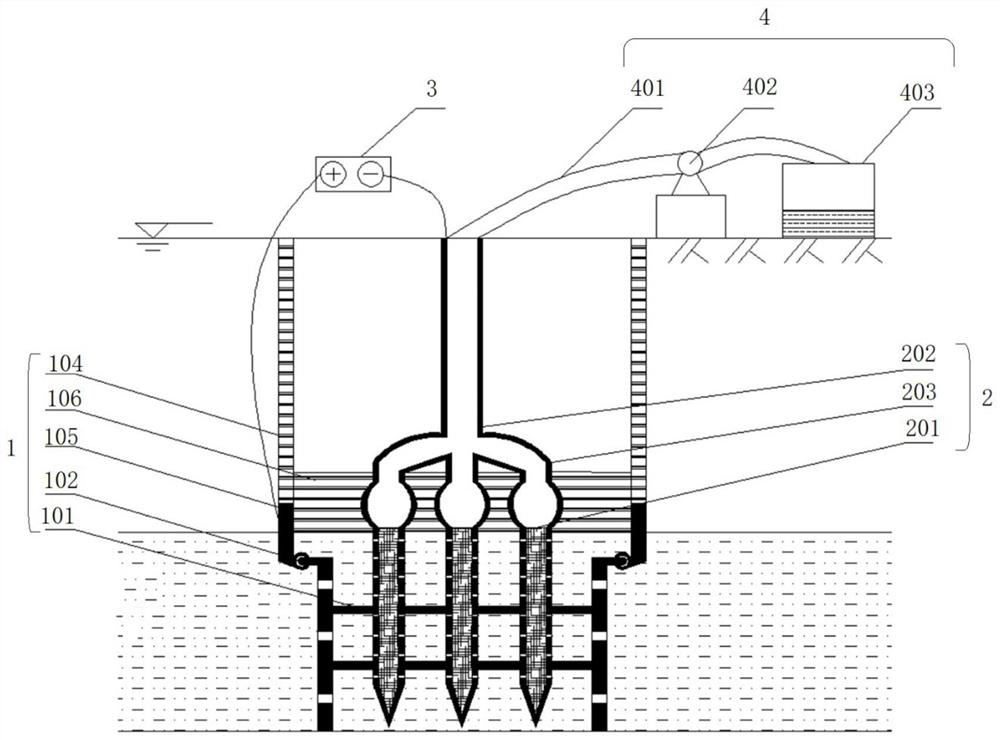

[0039] Such as figure 1 The shown in-situ solidification river silt device includes:

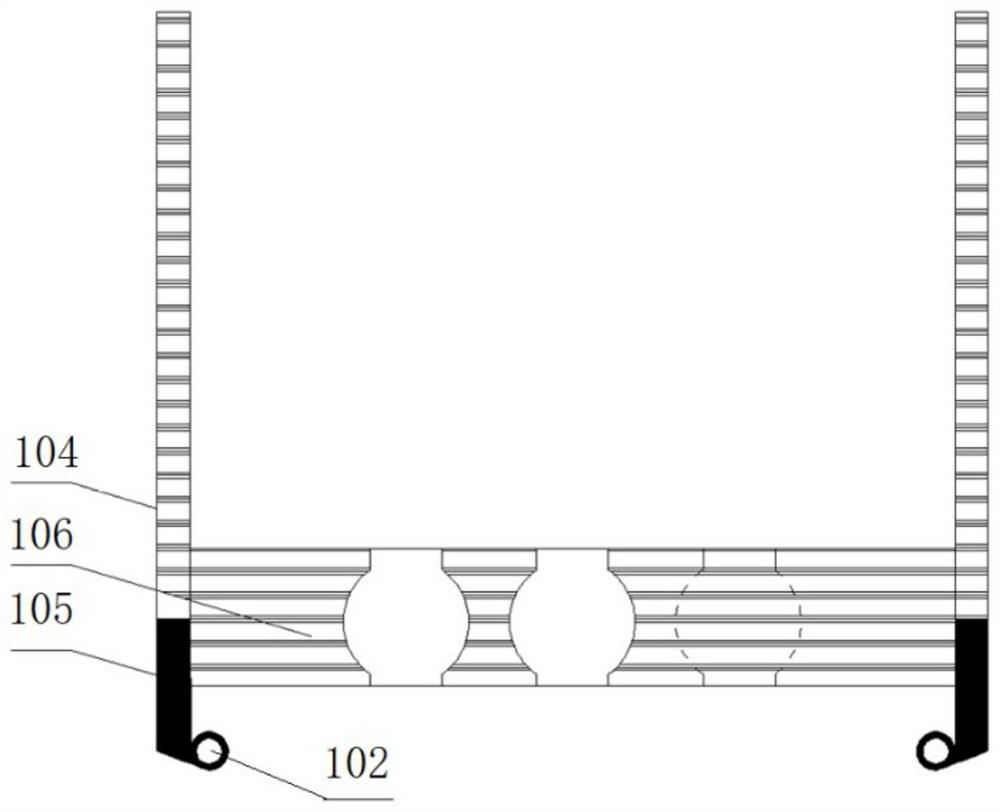

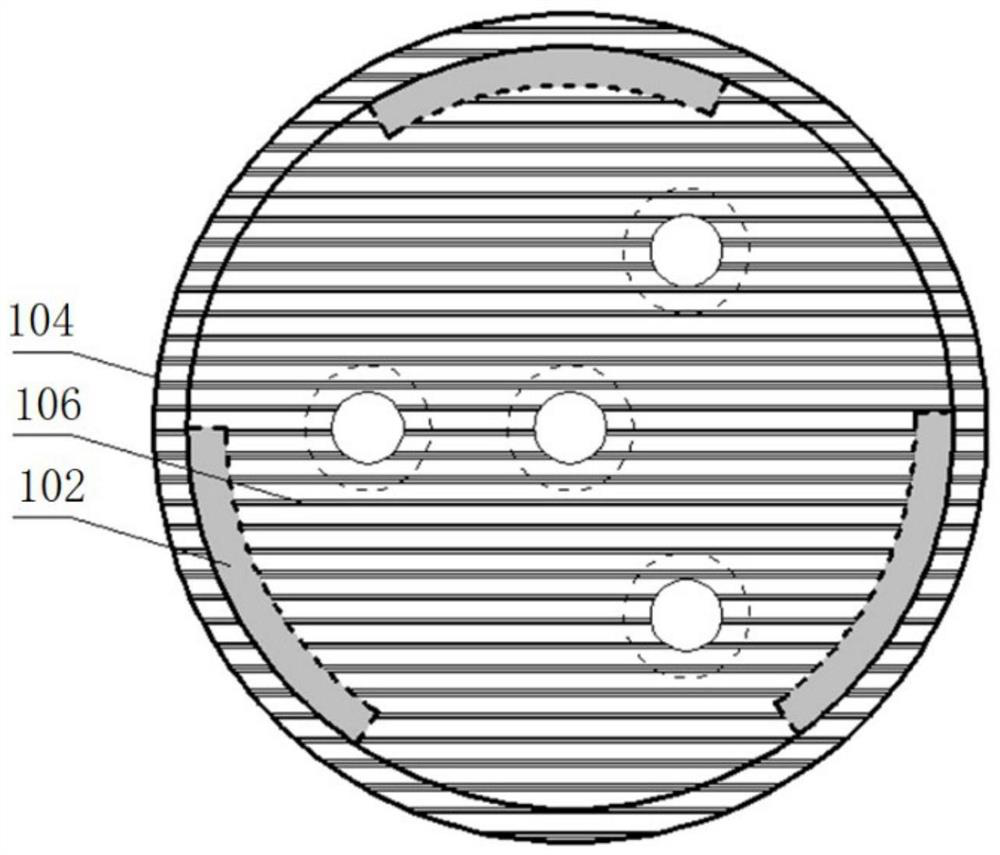

[0040] The partition conductive outer cylinder 1 is inserted from the water surface and extends into the mud, the part of the partition conductive outer cylinder 1 located in the mud is provided with a horizontally arranged conductive mesh 101, and the cylinder wall located in the mud Create multiple holes.

[0041] Conductive drainage pipe 2, the conductive drainage pipe 2 is inserted from the inside of the partition conductive outer cylinder 1 from the water surface and extends into the mud, the conductive drainage pipe 2 is inserted on the conductive mesh 101, and a plurality of hole, the conductive drainage pipe 2 is provided with mud filter cotton 201.

[0042] A DC power supply 3, the positive and negative poles of the DC power supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com