Injection molding apparatus and injection molding method

An injection molding and equipment technology, applied in the field of injection molding equipment and injection molding, can solve the problems of no mold exhaust design, uneven gas pressure distribution, difficult gas control, etc., to achieve good mold exhaust design, avoid gas Effects of uneven pressure distribution, good quality and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Reference will now be made in detail to the exemplary embodiments of the present invention, examples of which are illustrated in the accompanying drawings. Wherever possible, the same reference numbers are used in the drawings and descriptions to refer to the same or like parts.

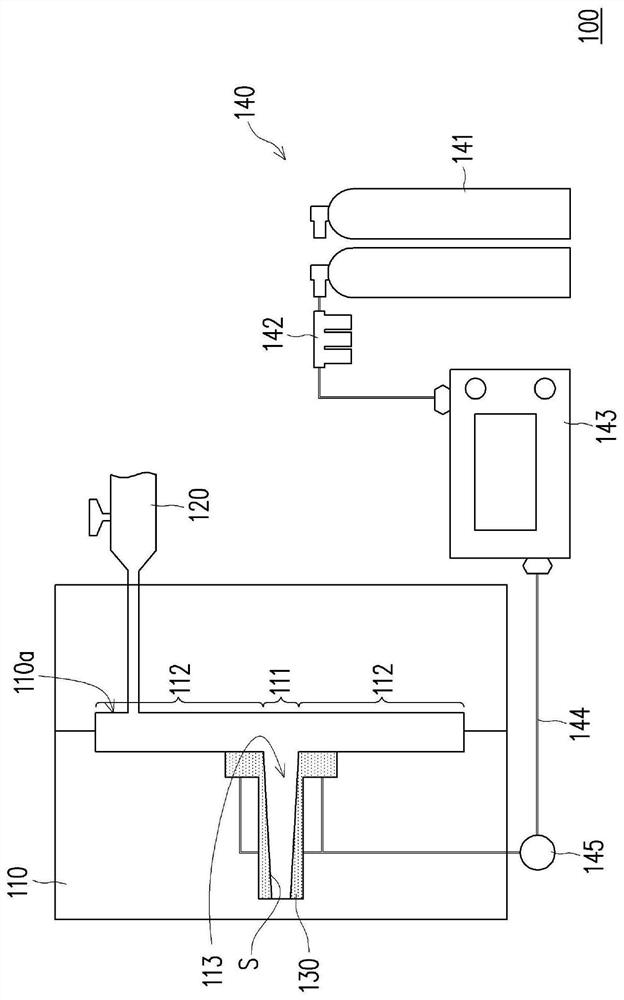

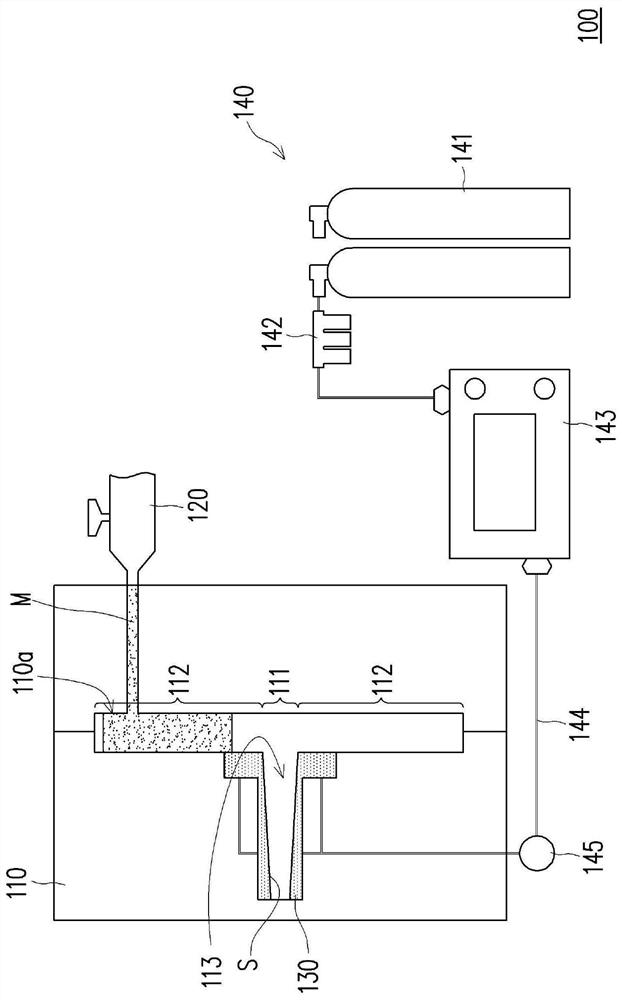

[0021] figure 1 It is a schematic diagram of an injection molding device according to an embodiment of the present invention. Please refer to figure 1 , the injection molding equipment 100 includes a mold 110 , an injection device 120 , a porous structure 130 and a gas driving unit 140 . The mold 110 has a mold cavity 110a. The injection device 120 is suitable for injecting the material M ( Figure 3A ) to the mold cavity 110a so that the material M ( Figure 3A ) is shaped into a molded object 50 ( Figure 3B ).

[0022] The porous structure 130 is disposed on the inner surface S of the mold cavity 110a. The gas driving unit 140 is connected to the mold 110 and is suitable for driving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com