Spraying arm assembly and cleaning machine applying same

A technology of spray arms and components, which is applied in the field of washing machines, can solve the problems of no water scouring effect in local areas, difficulty in covering the surface of tableware, and affecting the cleaning effect of tableware, so as to achieve random placement, eliminate cleaning dead ends, and improve jet flow The effect of coverage area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

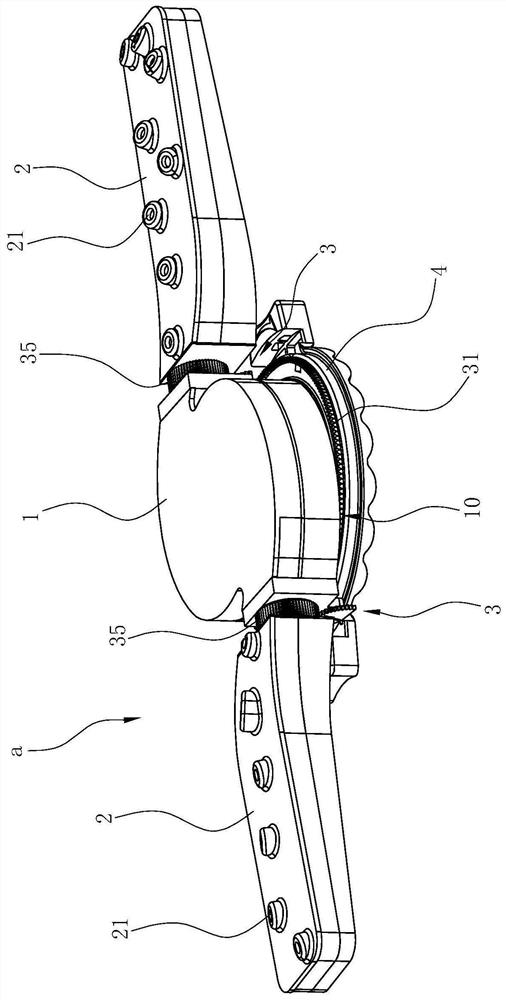

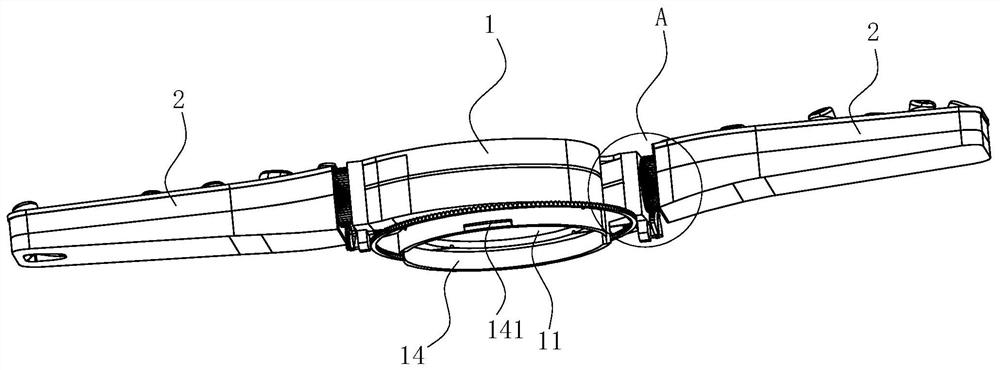

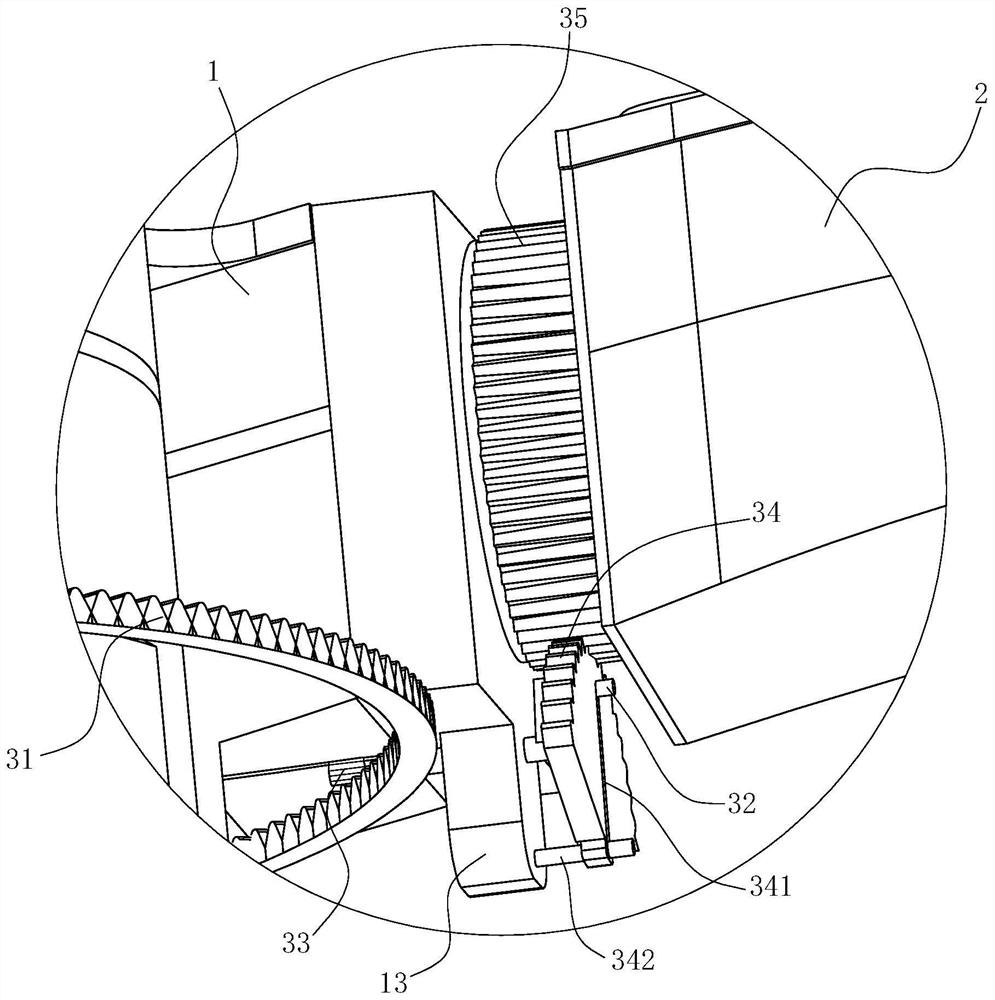

[0024] Such as Figure 1~4 As shown, the spray arm assembly of this embodiment includes a volute 1 and a spray arm 2. The bottom wall of the volute 1 is provided with a water inlet 11, and the side wall is provided with a water outlet 12. The spray arm 2 is rotatably connected to the volute 1. The water outlet 12 of the side wall and the upper wall are provided with spray holes 21, and the volute 1 is also provided with a transmission mechanism 3 that can drive the spray arm 2 to swing back and forth around the water outlet 12 when the volute 1 rotates. In this embodiment, the spray arms 2 are divided into two groups and arranged symmetrically with respect to the center of the volute 1, so as to further increase the range of spraying water.

[0025] In this embodiment, the lower side of the volute 1 is provided with a collar 4 that is detacha...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap