A rock-breaking device and its construction technology using high-frequency electric pulse assisted impact

A rock-breaking device and construction technology technology, applied in percussion drilling, construction, drilling equipment and methods, etc., can solve the problems of large pollution, large impact, high risk factor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

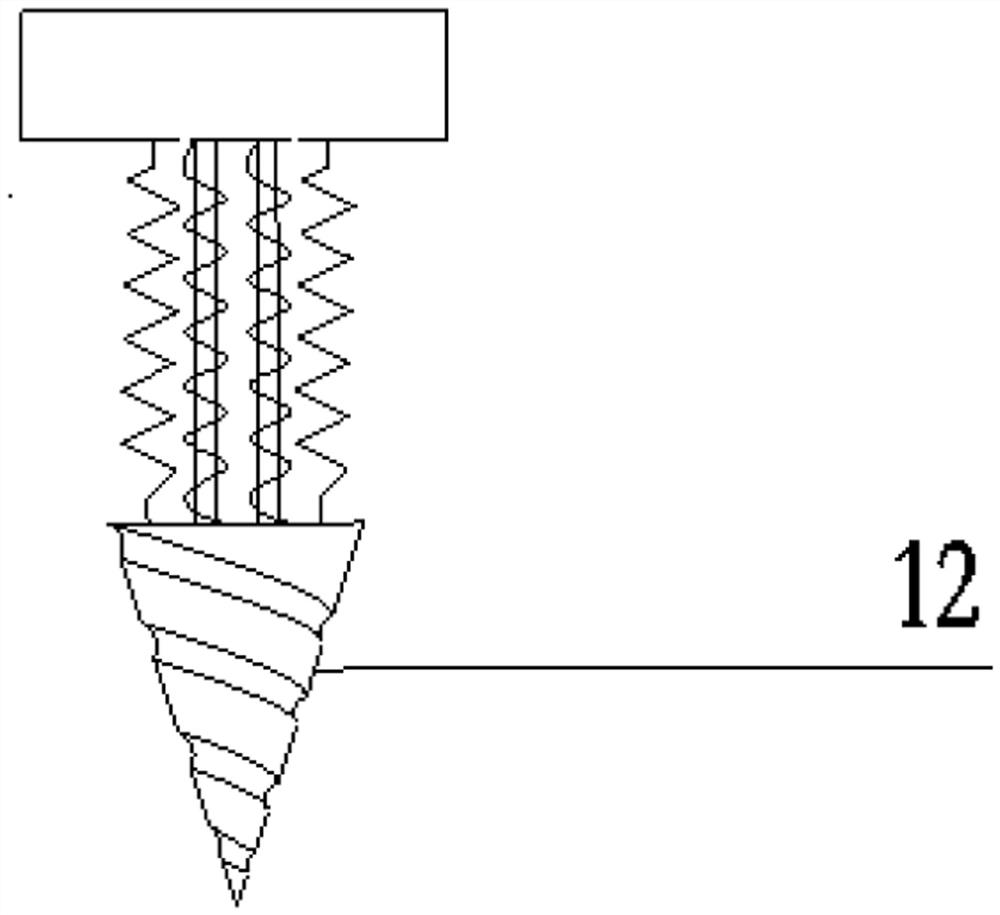

Embodiment 2

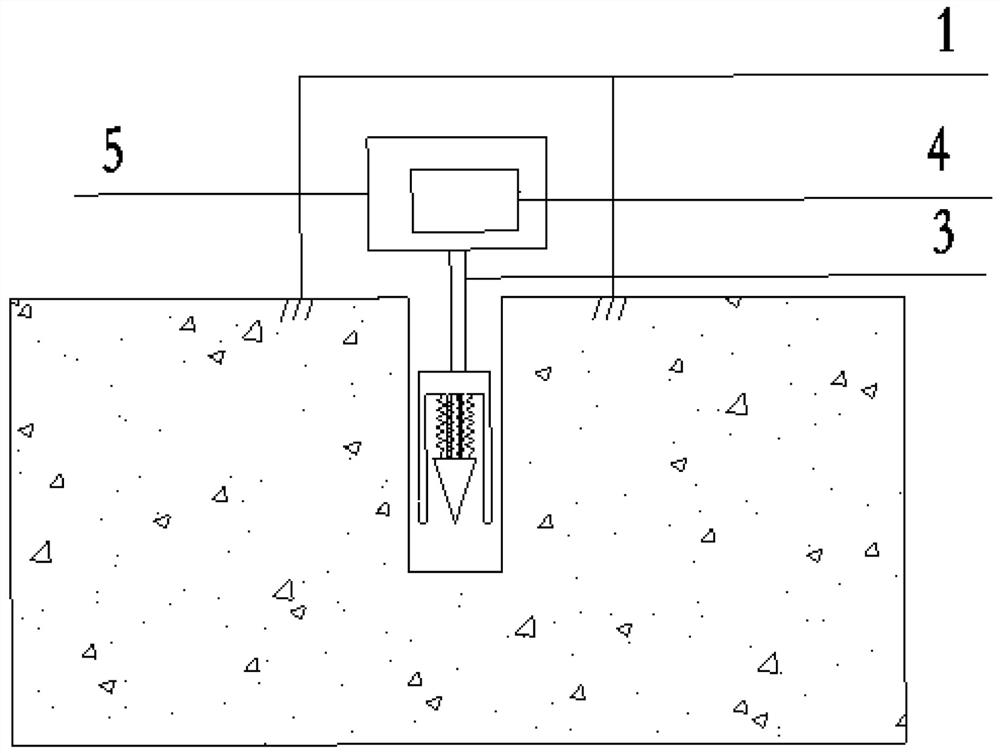

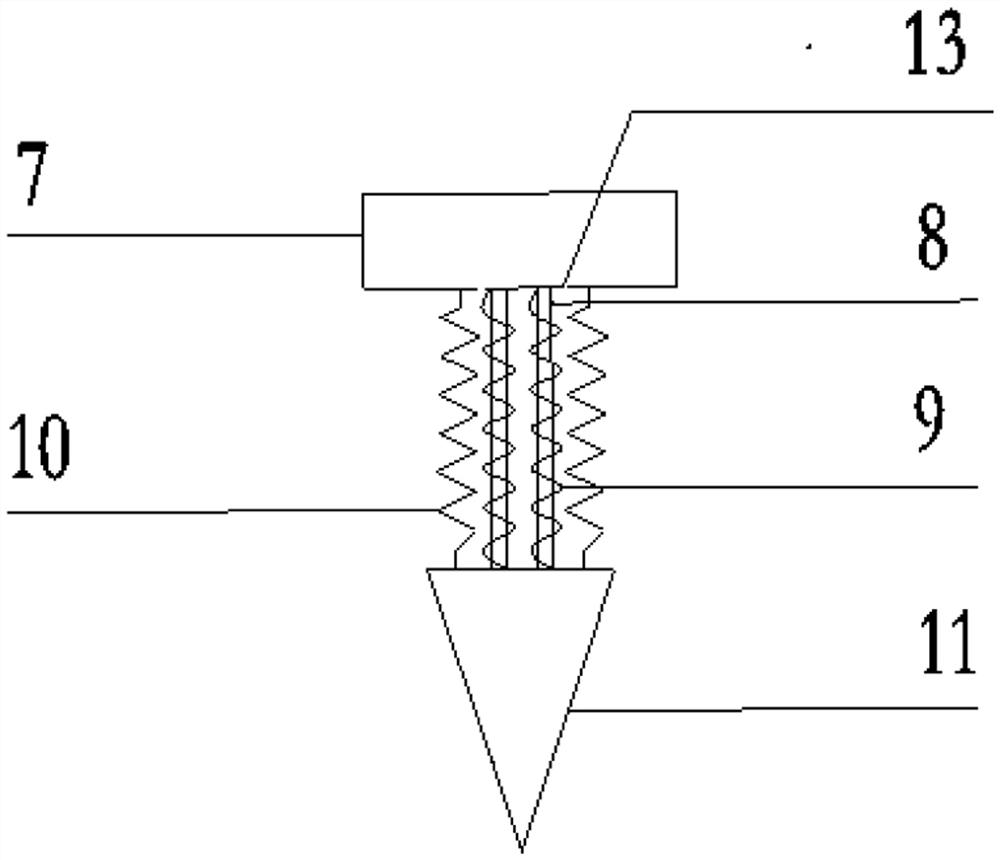

[0053] The longitudinal crushing construction technology of any one of the rock-breaking devices that utilize high-frequency electric pulses to assist impact, it includes the following steps:

[0054] Step1: Material preparation: reaction force frame 1, pillar 3, hollow metal rod, generator 4, wedge bit part 11, helical bit part 12, spring and coil;

[0055] Step2: Fixing device: the hand-held terminal control device is welded on the outside of the reaction frame 1;

[0056] Step3: Power generation device: the generator 4 is installed in the generator casing 5 and there will be no relative shaking, and the generator casing 5 is welded on the inner side of the reaction frame 1;

[0057] Step4: The connection between the rear end fixing device and the drill bit: the rear end of the pillar 3 is welded to the bottom center of the generator casing 5, and the front end is twisted to the top center of the metal shell of the drill bit through threads;

[0058] Step5: The distribution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com