Ultra-long bridge type stacking machine shared by multiple roadways

A stacker and multi-lane technology, which is applied in the field of logistics and warehousing automation, can solve the problems of large space occupied by the reel, large space occupied by the transition area, and high equipment cost, so as to achieve simple lifting and operating mechanism, improve space utilization, and improve The effect of delivery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

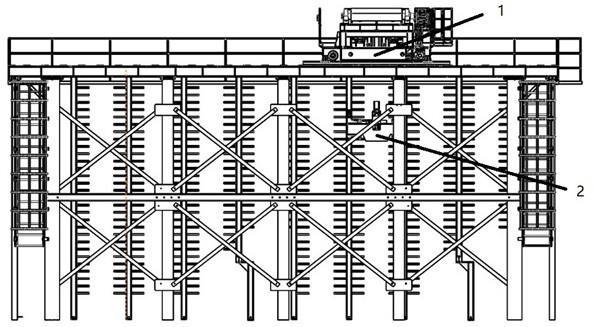

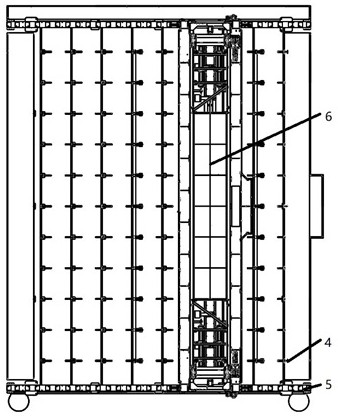

[0053] refer to Figure 1-16 ,

[0054] Such as Figure 1-3 As shown, a bridge-type stacker shared by super-long multiple lanes is used to pick and place goods on the shelf. One end of the lifting mechanism 3 is fixed on the horizontal mechanism 1, and one end is connected with the cargo platform 2, which is mainly used for lifting the cargo platform 2, and can put the cargo platform 2 into the belly of the horizontal mechanism 1; the horizontal mechanism 1 It is installed on the upper part of the shelf, and can carry the cargo platform 2 to run horizontally on the upper part of the shelf, and then realize the lifting and lowering of the cargo platform 2 between different lanes of the shelf through the lifting mechanism 3;

[0055] Such as image 3 and 4 , the upper and lower ends of the shelf are provided with H-shaped steel 4 along the horizontal direction and perpendicular to the ground. The number of H-shaped steel 4 is twice the number of roadways, and the number of H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com