Three-station fully-closed cylindrical sand blasting machine

A fully enclosed, sandblasting machine technology, applied in the direction of abrasive jetting machine tools, manufacturing tools, metal processing equipment, etc., can solve the problems of low processing production efficiency, poor processing quality, time-consuming and laborious, and achieve the effect of preventing dust from coming out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

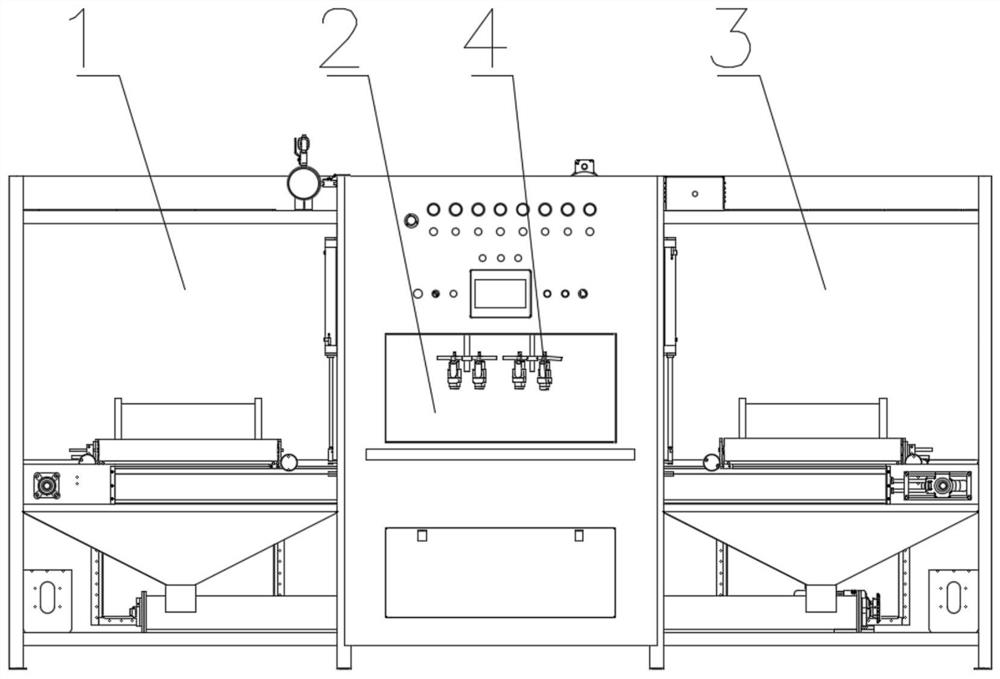

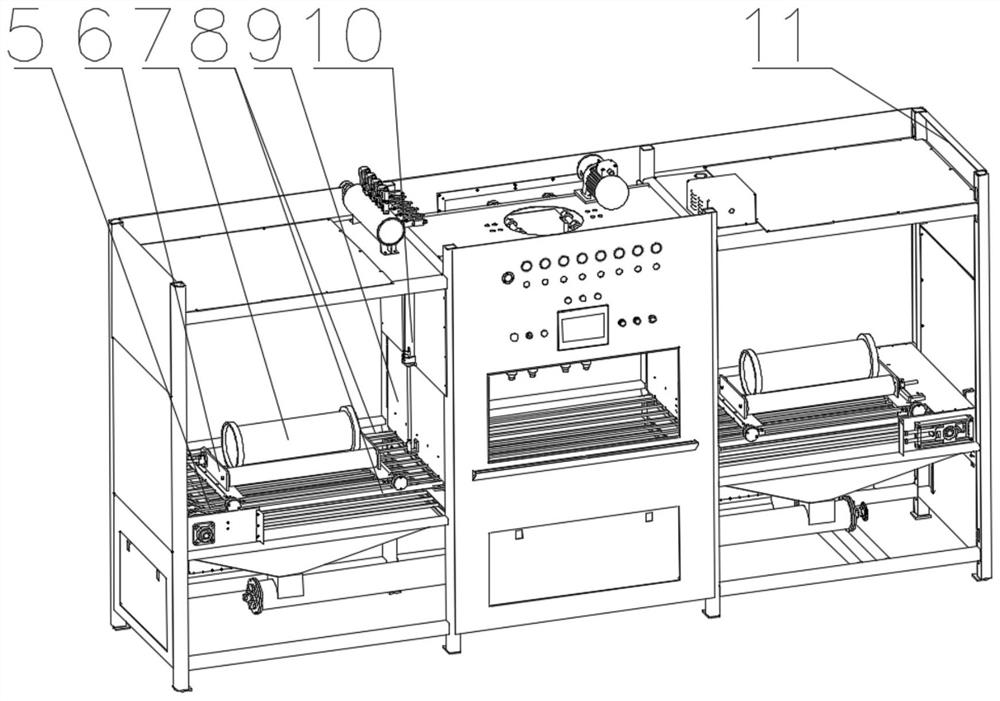

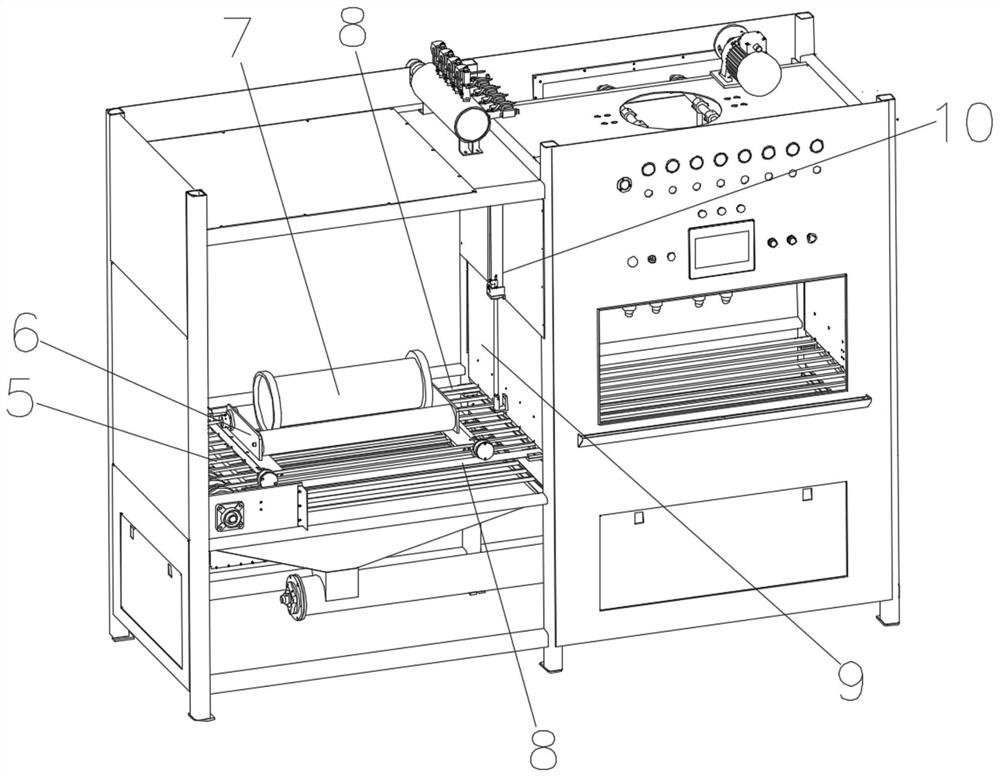

[0024] The overall structure of the device is as follows figure 1 and figure 2 As shown, a three-station fully enclosed cylinder sandblasting machine, its main body is divided into three stations, namely the sandblasting station and two feeding and discharging stations, and the two feeding and discharging stations are located at the side of the sandblasting station. sides. The three stations are specifically the left station 1, the middle station 2 and the right station 3. The left station 1 and right station 3 are the stations for picking and placing workpieces; the middle station 2 is the sandblasting cabin, and the parts of the left station 1 or right station 3 enter the sandblasting cabin of the middle station 2 for sandblasting operation . Several spray guns 4 arranged in a matrix are arranged in the sandblasting cabin 2, and the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com