Laser marking device and process for tire production

A laser marking and tire technology, applied in auxiliary devices, laser welding equipment, manufacturing tools, etc., can solve the problems of poor use effect, prolonged tire positioning time, and inability to turn tires, etc., and achieve good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

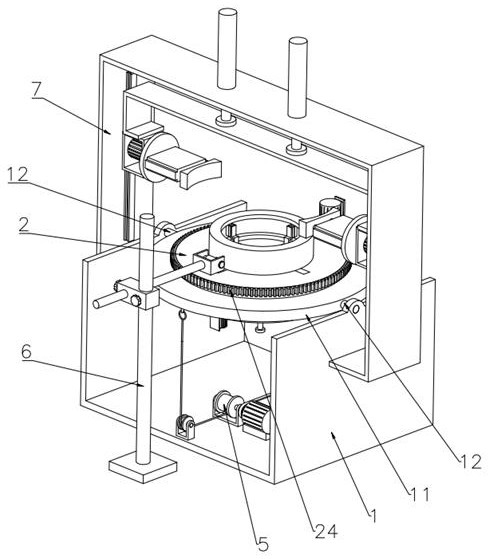

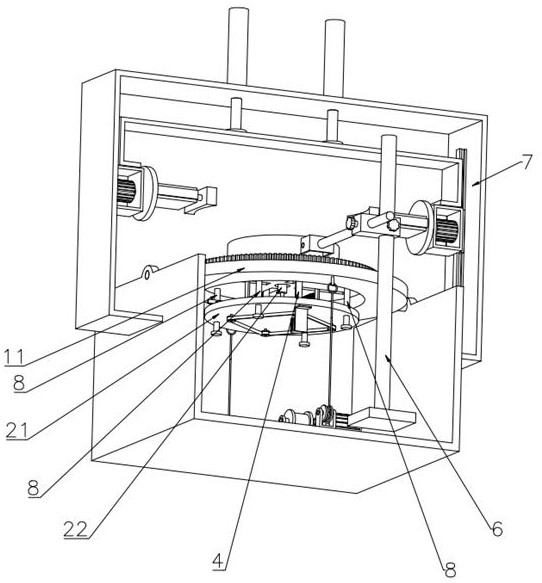

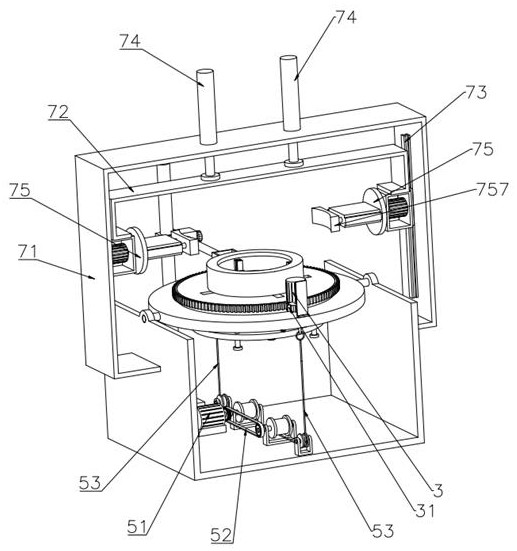

[0039] Such as Figure 1-Figure 12 As shown, a laser marking device for tire production provided by the present invention includes a U-shaped frame 1, an overturning ring 11 and two rotating shafts 12, and also includes a fixed plate 2, a lifting plate 21, an electric push rod 22, and a connecting plate 23 , circular rack 24, rotating motor 3, rotating gear 31, positioning assembly 4, overturning assembly 5, marking assembly 6, overturning assembly 7 and four sliding columns 8, two rotating shafts 12 are installed on U-shaped frame 1 for rotation The top of the flip ring 11 is fixedly connected to the two rotating shafts 12 on both sides, the top of the flip ring 11 is provided with an annular chute 111, the fixed disk 2 is arranged on the top of the flip ring 11, and the fixed disk 2 and the annular chute 111 Sliding fit, the four sliding columns 8 are rectangularly distributed on the bottom of the fixed plate 2, and the bottom ends of the four sliding columns 8 extend to the...

Embodiment 2

[0047] The process of a laser marking device for tire production provided by the present invention comprises the following steps,

[0048] Step S1, place the tire on the top of the fixed plate 2, and the positioning assembly 4 performs collision positioning on the inner wall of the tire, the rotating motor 3 drives the rotating gear 31 to rotate, the rotating gear 31 drives the circular rack 24 to rotate, and the circular rack 24 drives The fixed disk 2 rotates on the annular chute 111, the fixed disk 2 drives the tire to rotate, and the marking assembly 6 engraves patterns on the outer peripheral surface of the rotating tire;

[0049] Step S2, the overturning motor 51 drives the sprocket 540 in one of the overturning parts 53 to rotate, the sprocket 540 drives the winding shaft 532 to rotate, the winding shaft 532 drives the winding roller 533 to rotate, the winding roller 533 drives the steel rope 539 to wind and rewind, and the steel rope 539 utilizes the pulley 535 to pull...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com