Snow pear and loquat flavored fermented milk and preparation method thereof

A technology of fermented milk and loquat, applied in dairy products, other dairy products, milk preparations, etc., can solve problems such as insufficient fruit nutrient absorption, product whey precipitation system, and unfavorable human health, so as to avoid whey precipitation, Improve flavor and taste, and aroma coordination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

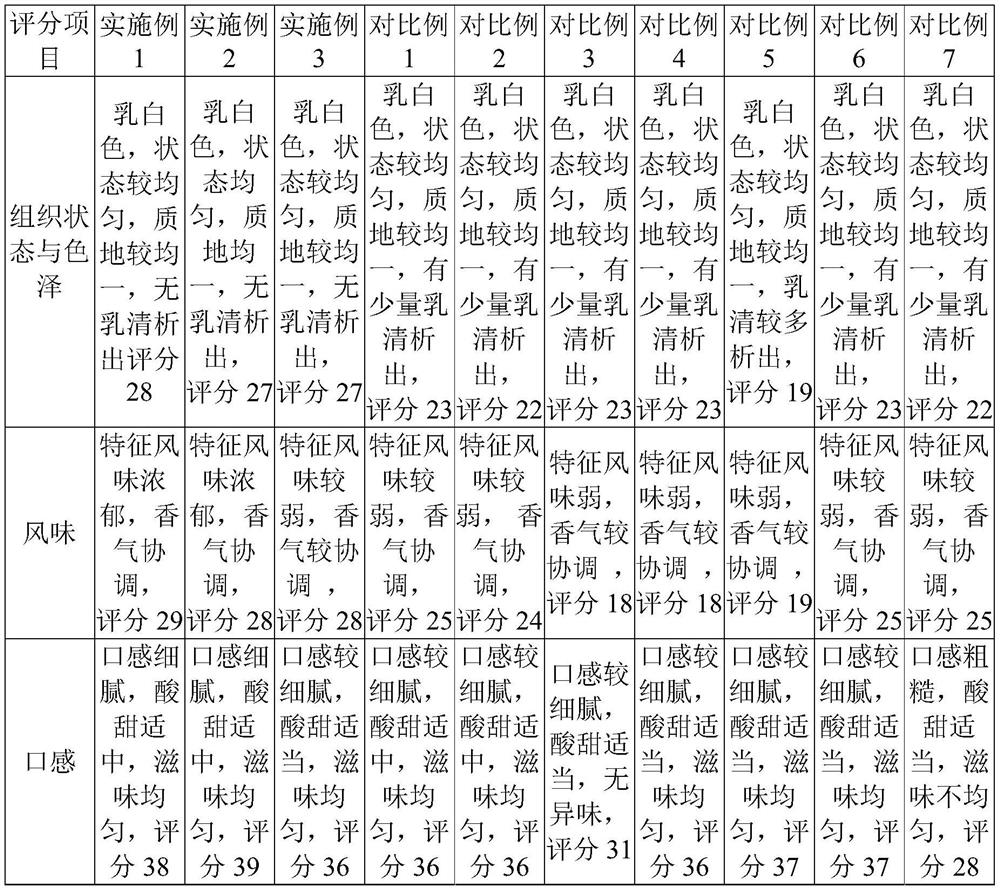

Examples

Embodiment 1

[0044] This example provides a method for preparing Sydney loquat-flavored fermented milk, including two processes of fruit juice preparation and fermented milk preparation, specifically including the following steps:

[0045] 1. Juice preparation:

[0046] (1) Select fresh pears and loquats with a weight ratio of 7:3, wash, peel, split, and pit them for later use.

[0047] (2) Boil pears and loquats with a mixed solution containing 0.3wt% ascorbic acid and 0.5wt% citric acid (that is, the temperature is 100°C) and scald for 90s, add water to make a slurry, and soften the slurry for 120min with an ultrasonic power of 800W in an ultrasonic device to obtain Original juice and pomace.

[0048] (3) Add 0.2% pectinase by weight of the pomace to the pomace, enzymolyze it in a water bath at 45° C. for 90 minutes, and then mix it with the original juice to obtain Sydney loquat pulp.

[0049] (4) Weigh 0.5g carboxymethyl chitosan, add 4ml, 1% acetic acid solution and stir to form a p...

Embodiment 2

[0057] This example provides a method for preparing pear and loquat flavor fermented milk, including two processes of fruit juice preparation and fermented milk preparation:

[0058] 1, the preparation method of fruit juice: adopt the preparation method identical with embodiment 1, obtain mixed fruit juice;

[0059] 2. The preparation of yogurt comprises the following steps:

[0060] (1) Ingredients: 935.65g fresh milk, 15g white granulated sugar, 30g fructose syrup, 9g compound stabilizer (composed of acetylated distarch adipate 6g, agar 3g), 0.35g sweetener (trichloro Mix 0.05 g of sucrose, 0.3 g of acesulfame potassium, and 10 g of mixed fruit juice (without water), and stir at 55°C for 25 minutes to obtain the base material;

[0061] (2) Degas the base material at 65°C and 18MPa, then homogenize at 30 / 180bar pressure, and then sterilize at 93°C for 300s;

[0062] (3) Cool the sterilized base material to 40-43°C, add 0.02g starter (comprising 0.01g each of Streptococcus t...

Embodiment 3

[0065] This embodiment provides a method for preparing fermented milk with pear and loquat flavor, wherein the method and operating parameters for fruit juice preparation are the same as in Example 1, and the preparation of fermented milk includes the following steps:

[0066] (1) batching: base material composition and concrete operation are with embodiment 1;

[0067] (2) Degas the base material at 55°C and 18MPa, homogenize it at 30 / 180bar pressure, and then sterilize at 85°C for 280s;

[0068] (3) Cool the sterilized base material to 40-43°C, add a starter (same as Example 1), pass through a fermenter filled with nitrogen through a sterile filter device, and ferment at 43°C, and the acidity reaches 70-75 Stop fermentation at °T;

[0069] (4) Filling: filling and sealing are carried out in a closed aseptic filling equipment. Nitrogen gas is filled in the filling machine, and the filled yoghurt is refrigerated at 6° C. and ripened to obtain Sydney loquat flavored fermented ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com