Switching contact arrangement of a low voltage circuit breaker

A low-voltage circuit breaker and contact technology, which is applied to circuit breaker parts, electric switches, circuits, etc., can solve problems such as contact force and structural design difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

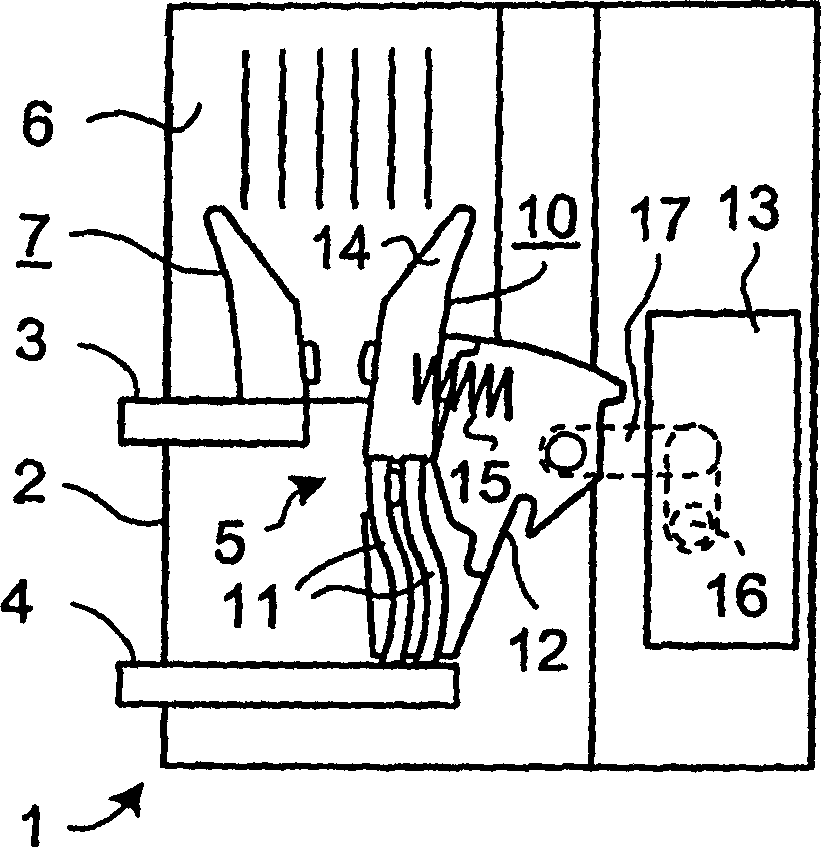

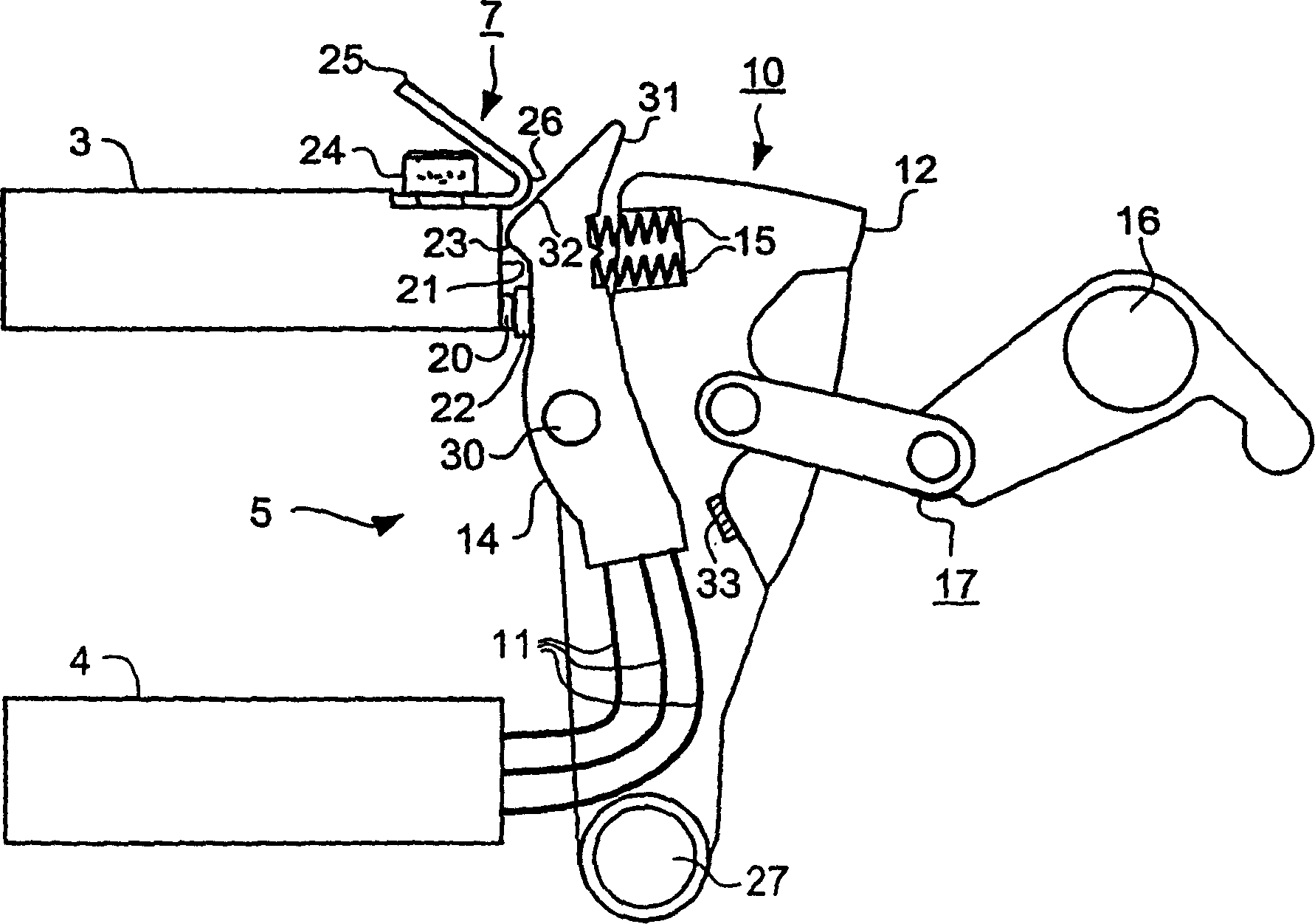

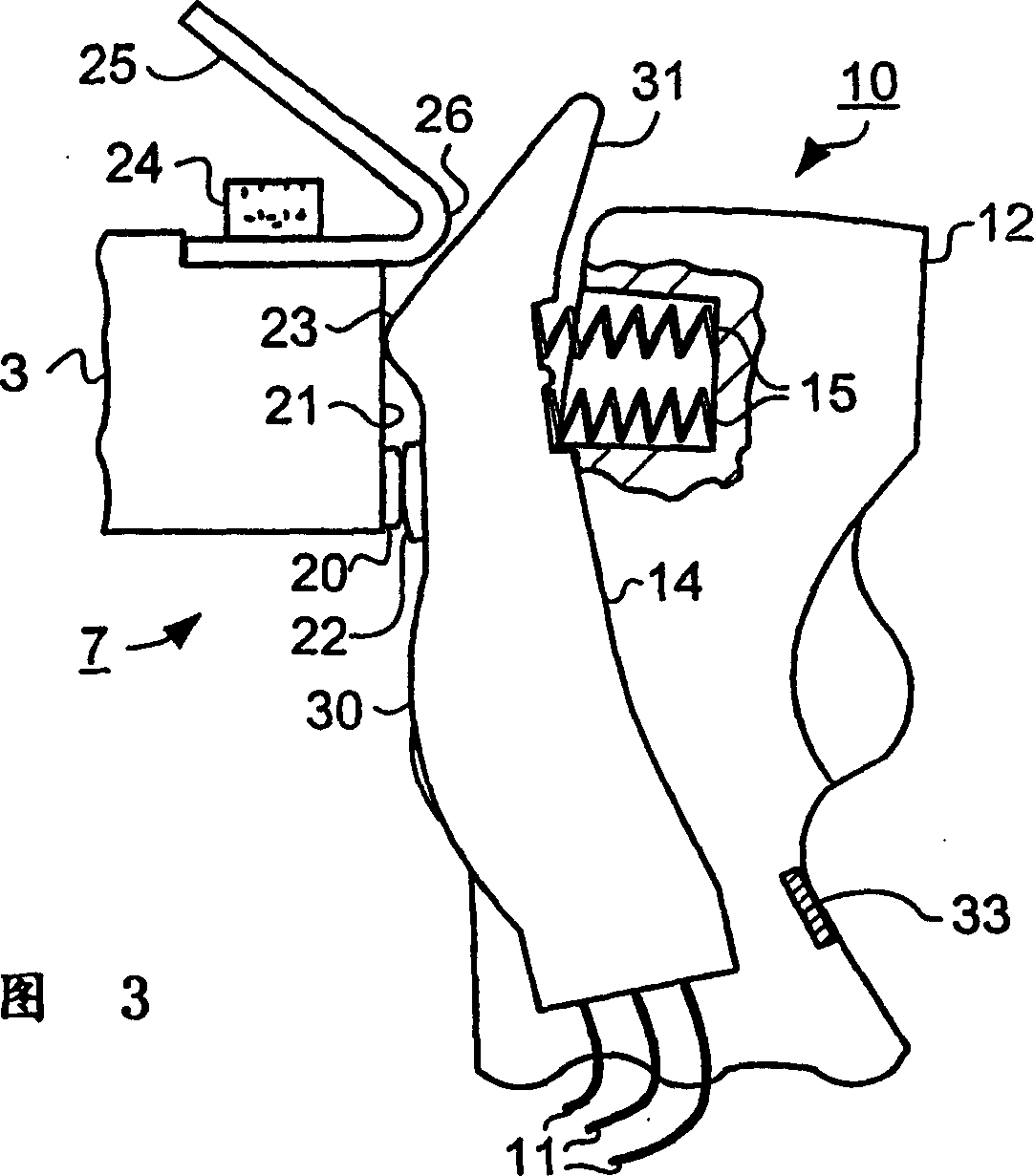

[0033] exist figure 1 A multipole low-voltage circuit breaker 1 is shown in simplified cross-section in FIG. 1 , which has a housing 2 and busbars 3 and 4 protruding from the rear of the housing. A switch contact structure, indicated generally at 5, is electrically connected to the bus bars 3 and 4 and is capable of switching on or off a user (not shown) circuit. The quenching chamber 6 is located in the housing 2 above the switching contact arrangement 5 and contains, in a known manner, arc barriers arranged perpendicularly to the switching arc. The switch contact structure 5 includes a static contact set 7 connected to the upper bus bar 3 , and a moving contact set 10 connected to the lower bus bar 4 through a bendable wire 11 . The contact support 12 belongs to the moving contact group 10 , and the contact support is swingably installed inside the housing 2 of the circuit breaker 1 , and can be switched on and off by the driving device 13 . The swingable contact lever 14 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com