Welding gun angle real-time automatic adjusting device

An automatic adjustment device and welding torch technology, which is applied in the direction of auxiliary equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of complex welding control system and difficult adjustment of welding torch posture, and achieve a wide range of applications and simplify the automatic welding equipment. Control system, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific embodiments.

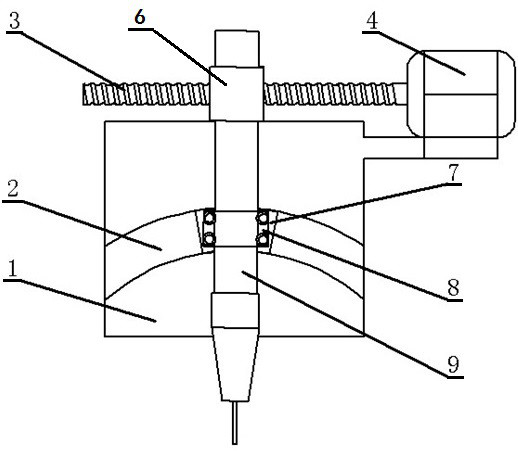

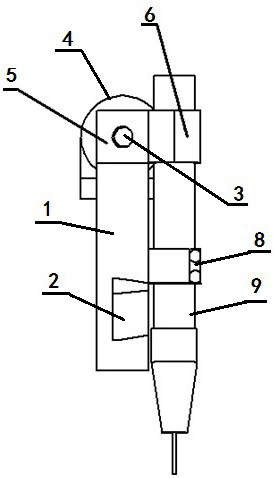

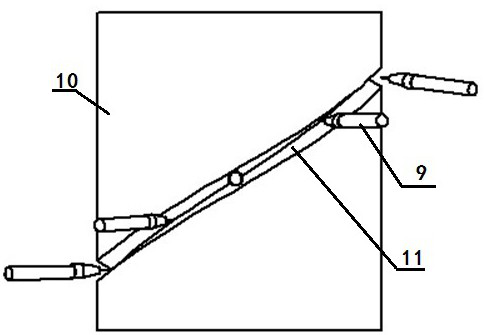

[0017] like figure 1 , figure 2 As shown, a device for automatically adjusting the angle of a welding torch in real time according to the present invention includes a mounting plate 1, an arc-shaped groove is opened on the mounting plate 1, and an arc-shaped guide rail 2 is installed in the arc-shaped groove; The guide rail 2 is fixedly connected with the middle part of the welding torch 9 through the locking device 8; the upper side of the mounting plate 1 is fixedly installed with a servo motor 4, and the rotation shaft of the servo motor 4 is connected with a ball screw 3 and a screw nut 5 Installed on the ball screw 3; the outer side of the screw nut 5 is fixedly connected with a sliding sleeve 6, and the sliding sleeve 6 is sleeved on the upper part of the welding torch 9.

[0018] The plane where the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com