Bulb, bulb production equipment and bulb production process

A technology for production equipment and light bulbs, applied in metal processing equipment, lighting and heating equipment, manufacturing tools, etc., can solve the problems of inconvenient assembly process of light bulbs and complicated assembly steps of light-emitting stems, so as to improve the convenience of assembly and optimize assembly process, the effect of ease of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The following is attached Figure 1-11 The application is described in further detail.

[0071] The embodiment of the present application provides a light bulb, adopting the following technical solution:

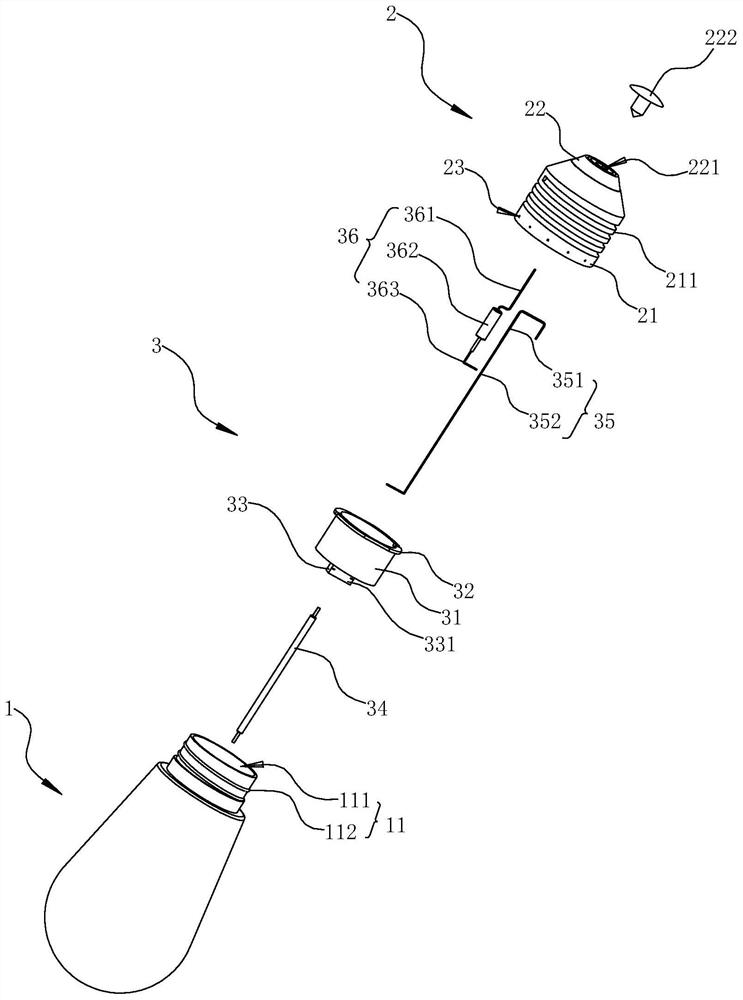

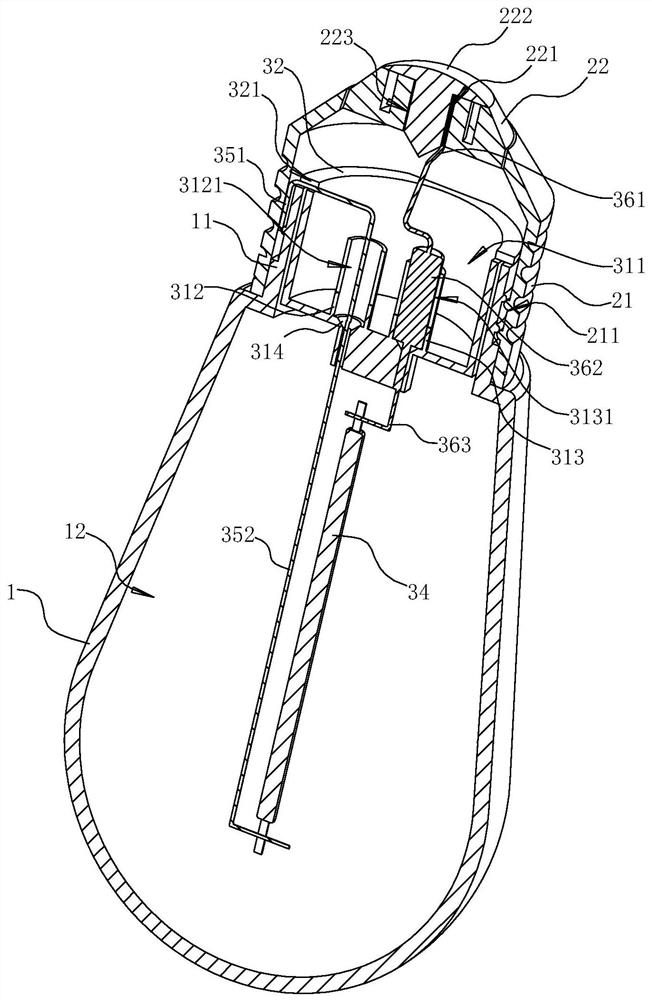

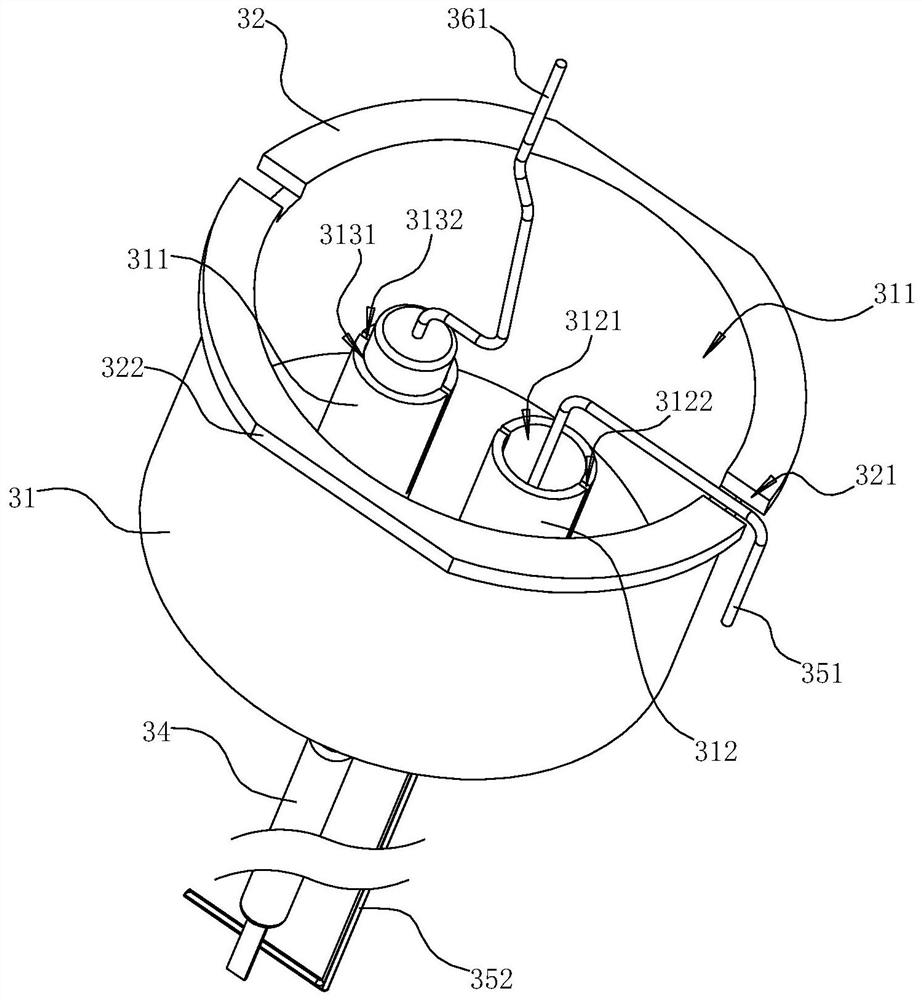

[0072] refer tofigure 1 , a light bulb, including a bulb shell 1, a lamp cap 2 and a light-emitting assembly 3, the light-emitting component 3 is detachably arranged in the bulb shell 1, and the lamp cap 2 is detachably set on the bulb shell 1.

[0073] refer to figure 1 , the bulb housing 1 has a mounting portion 11 and a bulb chamber 12, the mounting portion 11 is generally set in a hollow cylindrical shape, the mounting portion 11 is provided with a component mounting hole 111, and the outer peripheral surface of the mounting portion 11 is provided with a threaded flange 112, the component is installed The hole 111 communicates with the bulb cavity 12 , and the central axis of the component mounting hole 111 is collinear with the central axis of the mounting port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com