Friction-resistant structure of lifting table leg and mounting method of friction-resistant structure

An installation method and anti-friction technology, applied in the field of lifting tables, can solve the problems of noise generation, easy shaking, falling off to the outside, etc., to achieve the effect of prolonging the service life, small friction coefficient, and no noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

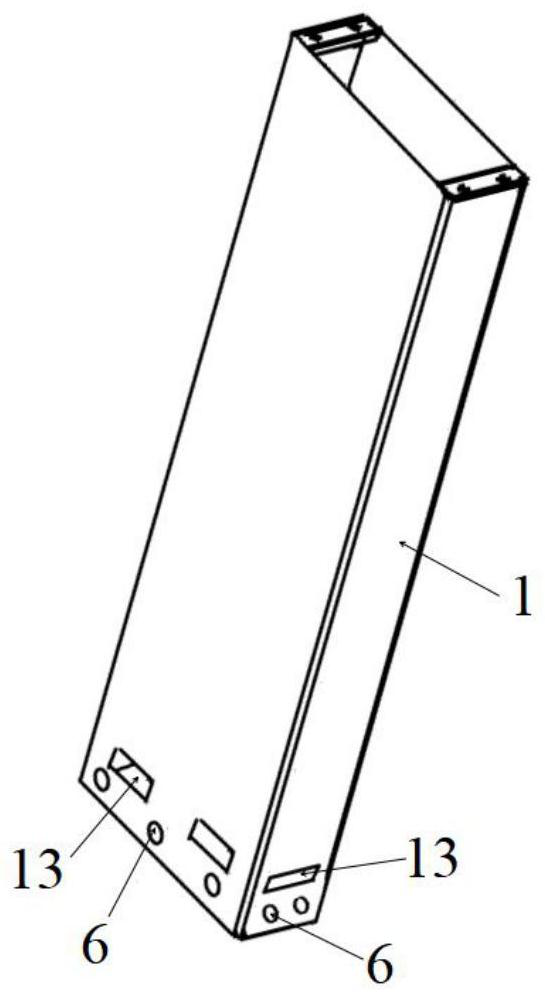

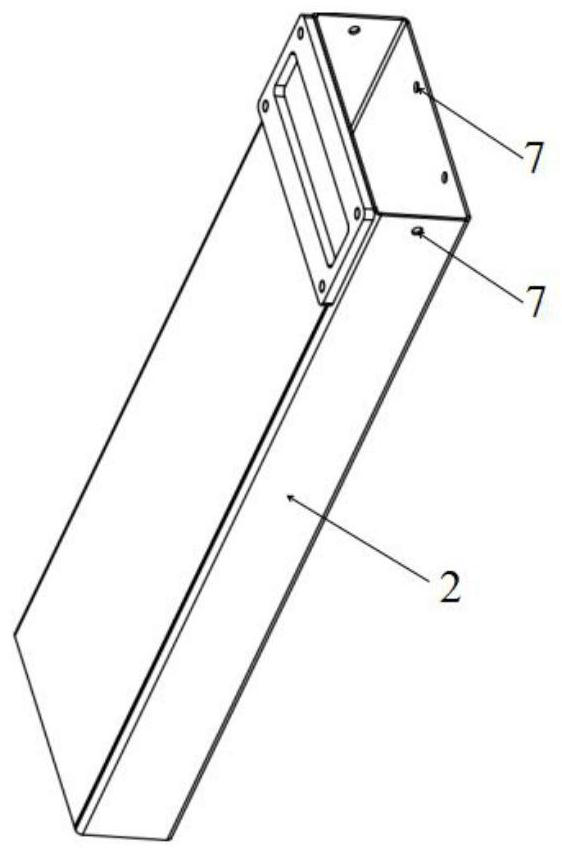

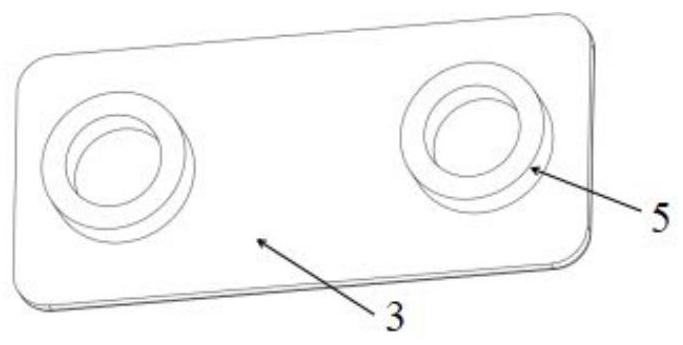

[0032] Such as Figure 1-7 As shown, the anti-friction structure of a lifting table leg and its installation method provided by the present invention include a lower wear-resistant plate 3 installed at the lower end of the inner tube 1 of the lifting table leg and an upper end of the outer tube 2 of the lifting table leg The upper wear-resistant sheet 4, the lower wear-resistant sheet 3 and the upper wear-resistant sheet 4 are polytetrafluoroethylene polymer materials, and one side of the lower wear-resistant sheet 3 is symmetrically provided with a first raised portion 5, The first raised portion 5 is hollow cylindrical, and the lower wear-resistant sheet 3 is divided into a 2-hole lower wear-resistant sheet and a 3-hole lower wear-resistant sheet according to the rectangular structure of the inner tube 1. The lower end of the inner tube 1 is connected to the lower wear-resistant A first connection hole 6 is provided at the corresponding position of the first protrusion 5 of ...

Embodiment 2

[0038] The structure of this embodiment is the same as that of Embodiment 1, and the similarities will not be repeated here. The difference between this embodiment and Example 1 is that the lower wear-resistant sheet 3 and the upper wear-resistant sheet 4 are both polyoxymethylene polymer materials, and since the cross-section of the inner and outer tubes is a square structure, the lower wear-resistant sheet 3 are lower wear-resistant sheets with 3 holes, each side wall of the inner tube 1 is provided with a corresponding first connecting hole 6, the upper wear-resistant sheet 4 is a square structure, and each of the three side walls is provided with two second convex holes. The three side walls of the outer tube 2 are correspondingly provided with two second connection holes 7 on the raised part 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com