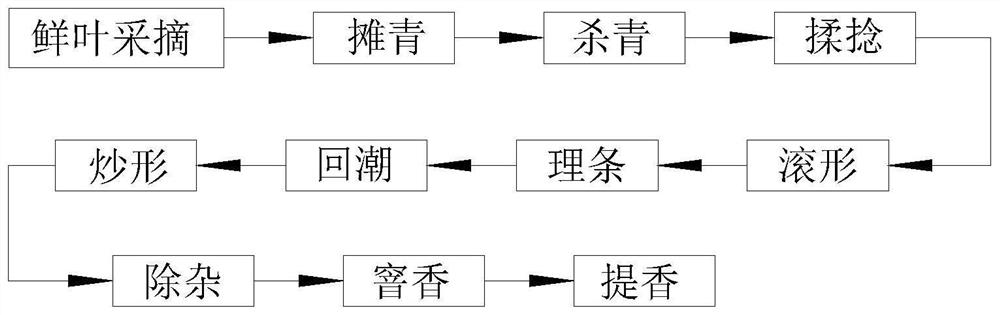

Making method of Huangshan Maofeng tea

A production method and Maofeng's technology, applied in the direction of tea processing before extraction, can solve the problems of weak taste, easy occurrence of scorched buds and leaves, and achieve the effects of good taste, solving technical obstacles, and improving quality and flavor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1: the preparation method of the Huangshan Maofeng whose fresh leaves are one bud and one leaf comprises the following steps:

[0049] 1) Picking fresh leaves: Picking buds and leaves from the origin of Huangshan Maofeng;

[0050] 2) Spread green: put the buds and leaves into the green stand machine, set the spread thickness to 4-5 cm, blow cold air on the fresh leaves, the cold air volume is 25-30m 3 / minute, the stalling time is 1.5-2.5 hours;

[0051] 3) Finishing: Transport the green tea after spreading to the roller finishing machine for segmental electromagnetic finishing. The temperature of the first stage of finishing is 200-205°C, the time of finishing is 2.5-3 minutes, and the temperature of the second stage is 170-175°C. , the finishing time is 3-3.5 minutes, and the finishing temperature in the third stage is 120-125°C and the finishing time is 2-2.5 minutes;

[0052] 4) Kneading: kneading for the first time for 1.5 minutes, and shaking once ev...

Embodiment 2

[0060] Embodiment 2: the preparation method of the Huangshan Maofeng that fresh leaf is a bud two leaves, comprises the following steps:

[0061] 1) Picking fresh leaves: Picking buds and leaves from the origin of Huangshan Maofeng;

[0062] 2) Spread green: put the buds and leaves into the green spread machine, set the spread thickness to 5-7 cm, blow cold air on the fresh leaves, the cold air volume is 26-28m 3 / minute, the stalling time is 1.2-2.3 hours;

[0063] 3) Finishing: Transport the green tea after spreading to the drum fixing machine for segmental electromagnetic finishing, wherein the temperature of the first stage of finishing is 205-207°C, the time of finishing is 2-2.5 minutes, and the temperature of the second stage of finishing is 172- 175, the finishing time is 3-3.5 minutes, the third stage finishing temperature is 120-125°C, and the finishing time is 2-2.2 minutes;

[0064] 4) Kneading: Knead for 2-2.5 minutes without pressure for the first time, shake ...

Embodiment 3

[0072] Embodiment 3: the preparation method of the Huangshan Maofeng that fresh leaf is a bud three leaves, comprises the following steps:

[0073] 1) Picking of fresh leaves: pick the buds and leaves of the origin of Huangshan Maofeng, one bud and three leaves;

[0074] 2) Green spreading: put the buds and leaves into the green spreading machine, set the spreading thickness to 6-7 cm, and use cold air to blow the tea leaves, the cold air volume is 25-30m 3 / minute, the stalling time is 2.3-2.5 hours;

[0075] 3) Finishing: Transport the green tea leaves to the drum electromagnetic finishing machine for segmented electromagnetic finishing. The temperature of the first stage is 206-208°C, the finishing time is 2.5-2.8 minutes, and the temperature of the second stage is 174- 1176°C, the finishing time is 3-3.5 minutes, the third stage finishing temperature is 125-128°C, and the finishing time is 2-2.5 minutes;

[0076] 4) Kneading: Knead for 2-2.5 minutes without pressure for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com