Rotary driving type full-automatic harvesting vehicle for hydroponic leaf vegetables

A rotary drive, fully automatic technology, applied to harvesters, agricultural machinery and implements, applications, etc., can solve the problems of low manual harvesting efficiency, high temperature, high humidity, etc., to reduce labor costs and improve harvesting efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Further description will be given below in conjunction with the embodiments shown in the accompanying drawings.

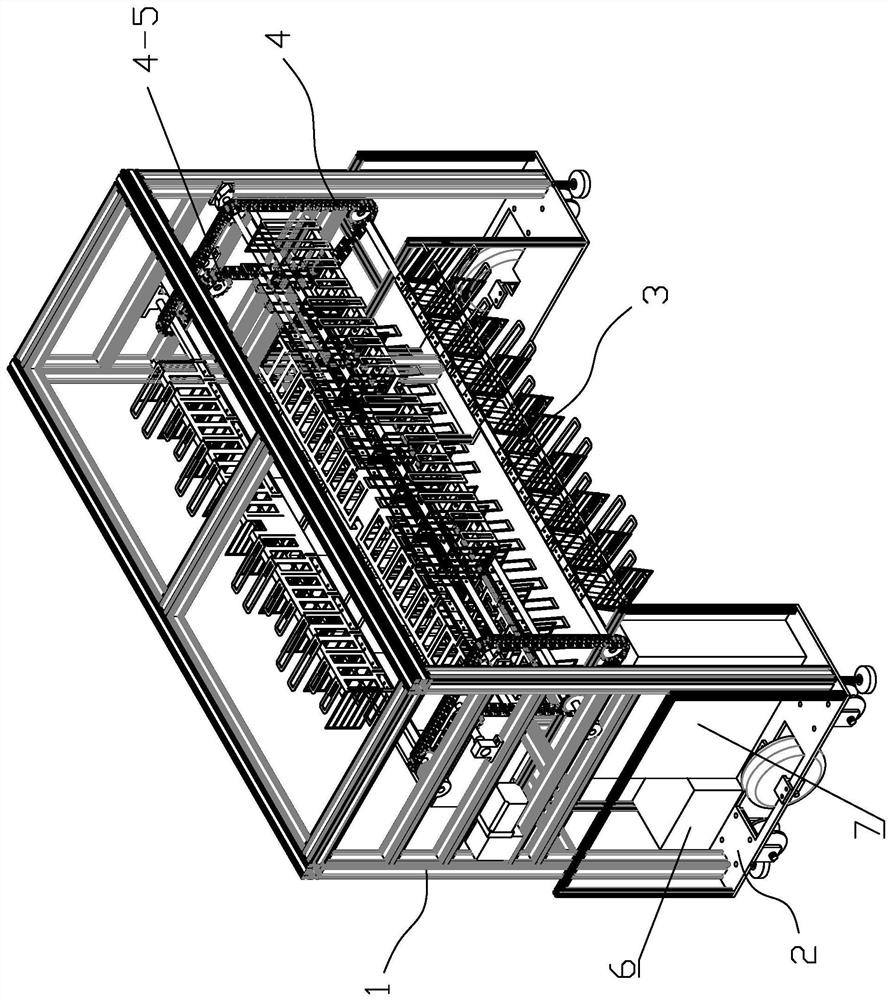

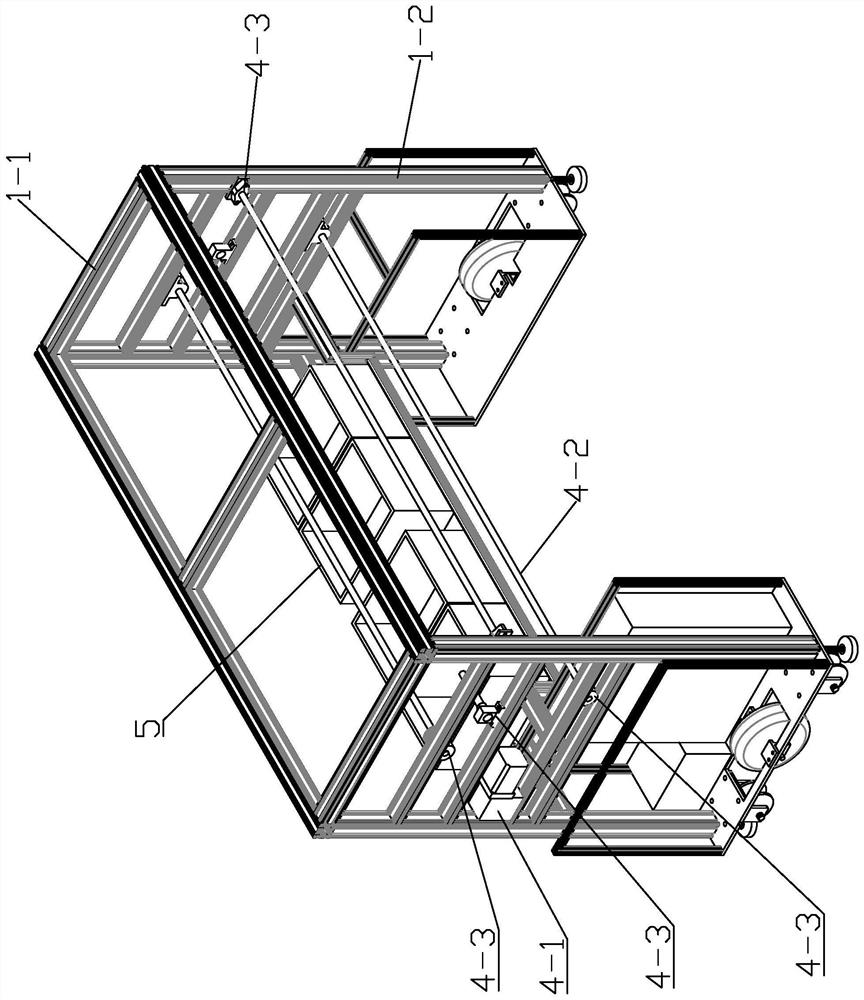

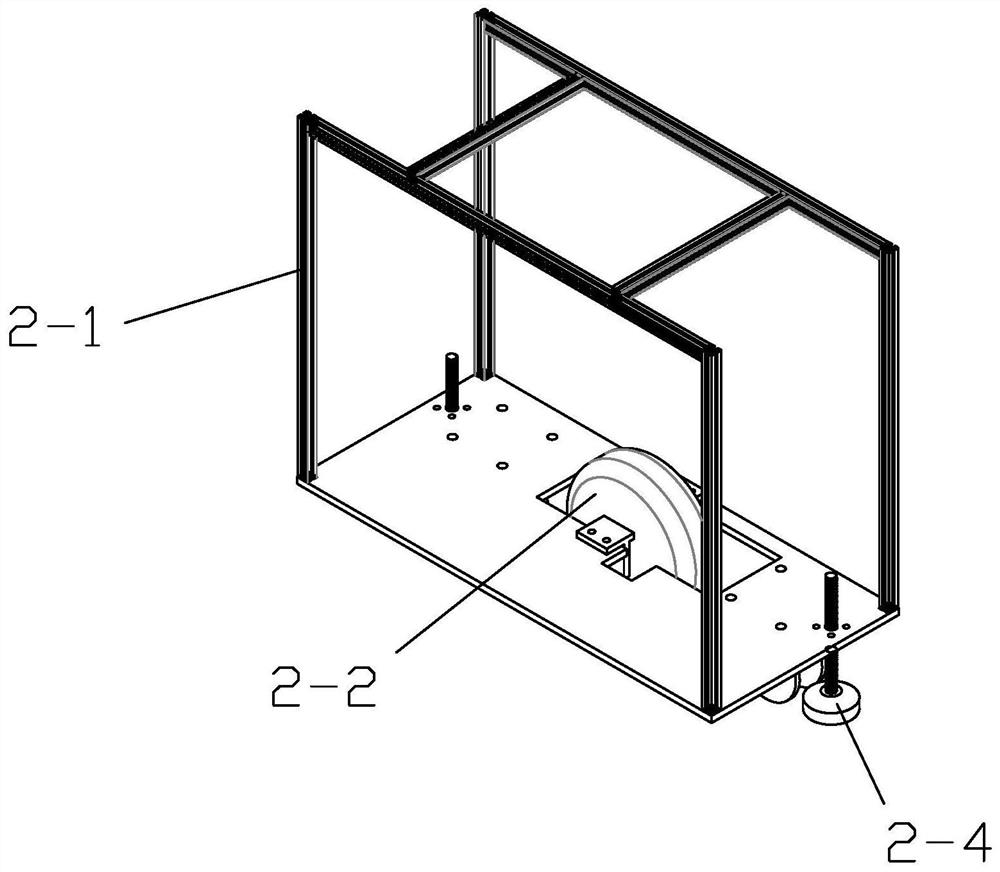

[0024] Such as figure 1 The shown rotary drive type fully automatic harvesting vehicle for hydroponic leaf vegetables includes a main frame 1, two sets of mobile components 2, several groups (four groups in the figure) harvesting components 3, drive components 4, several ( Four) vegetable basket 5, through-beam sensor (not shown in the figure), accumulator 6 and electric control box 7. The main frame is composed of several beams 1-1 and columns 1-2 and is arranged in a gantry type, so as to facilitate harvesting vehicles across the cultivation tank (filled with substrate or nutrient solution, used for cultivating leafy vegetables, not shown in the figure). display) for leaf vegetable harvesting. Four vegetable baskets are fixed on the main frame and arranged side by side under the harvesting assembly to receive the leafy vegetables picked by the harvesting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com