Physical deacidification and deodorization system for vegetable oil

A physical deacidification and vegetable oil technology, applied in the direction of fat oil/fat refining, fat production, etc., can solve the problems of poor pass rate of mycomycin content and plasticizer content detection, unstable process treatment effect, etc., to avoid glycidol Increased ester content, stable deodorization process, and remarkable deodorization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

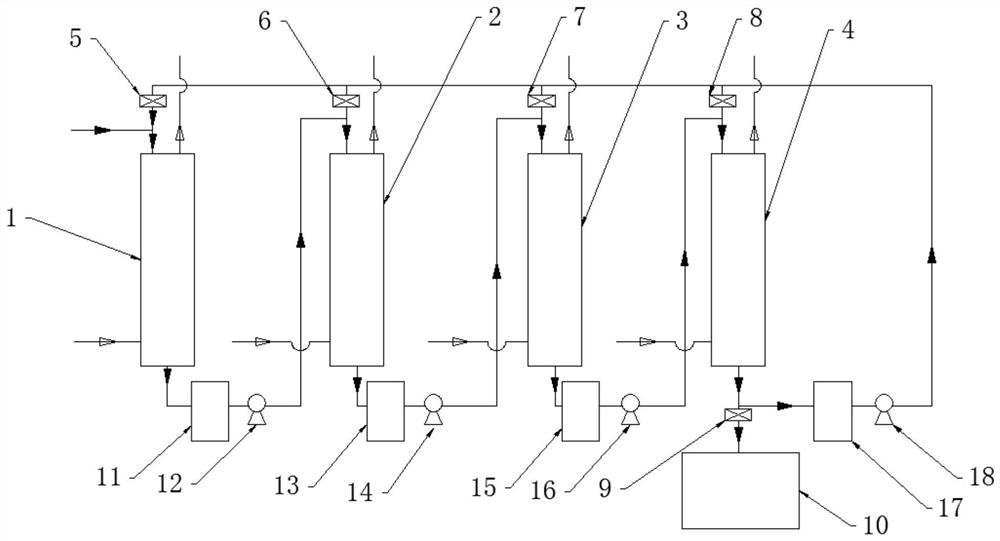

[0034] A physical deacidification and deodorization system for vegetable oil, including a set of processing devices;

[0035] The treatment device includes a dehydration tower 1, a deacidification tower 2, a decolorization tower 3 and a deodorization tower 4;

[0036] Dehydration tower 1, deacidification tower 2, decolorization tower 3 and deodorization tower 4 are packed towers;

[0037] The oil outlet of dehydration tower 1 is connected with the oil inlet of deacidification tower 2, the oil outlet of deacidification tower 2 is connected with the oil inlet of decolorization tower 3, the oil outlet of decolorization tower 3 is connected with the oil inlet of deodorization tower 4 Port connection; the vegetable crude oil is processed in a progressive temperature manner to avoid energy consumption caused by temperature fluctuations in the processing process of the vegetable crude oil, making the design of the deodorization system more reasonable;

[0038] The oil outlet of deod...

Embodiment 2

[0048] The difference from Example 1 is that the vacuum degree of the dehydration tower 1 is 9mbar, the temperature is 160°C, and the dehydration time is 7min;

[0049] The vacuum degree of deacidification tower 2 is 1mbar, the temperature is 230°C, and the deacidification time is 3min;

[0050] The vacuum degree of the decolorization tower 3 is 1.5mbar, the temperature is 240°C, and the decolorization time is 2min;

[0051] The vacuum degree of the deodorization tower 4 is 0.8mbar, the temperature is 260°C, and the deodorization time is 1min.

Embodiment 3

[0053] The difference from Example 1 is that the vacuum degree of the dehydration tower 1 is 11 mbar, the temperature is 150° C., and the dehydration time is 2 min;

[0054] The vacuum degree of the deacidification tower 2 is 1.5mbar, the temperature is 220°C, and the deacidification time is 10min;

[0055] The vacuum degree of the decolorization tower 3 is 1mbar, the temperature is 240°C, and the decolorization time is 8min;

[0056] The vacuum degree of the deodorization tower 4 is 1 mbar, the temperature is 270° C., and the deodorization time is 5 min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com