Atomization plate detection device

The technology of a detection device and an automatic detection device is applied in the directions of measurement device, measurement of electricity, measurement of electric variables, etc., which can solve the problems of long function detection time, high labor intensity, complicated operation, etc., to save labor costs, reduce labor intensity, The effect of improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] At present, in the process of mass production of humidifiers by small household appliance enterprises, the inspection of the atomization plate relies on manual inspection. The main operations of the atomization plate function test include: taking the atomization plate, docking the water tank, plugging in the test line, turning over the atomization plate, and turning on the power. There are multiple steps such as testing, pulling out the test line and wiping the residual water stains on the atomizing plate. The function detection takes a long time, requires a lot of manpower, labor intensity, and cumbersome operation. Factors such as these have seriously affected the production efficiency of humidifiers for home appliance companies.

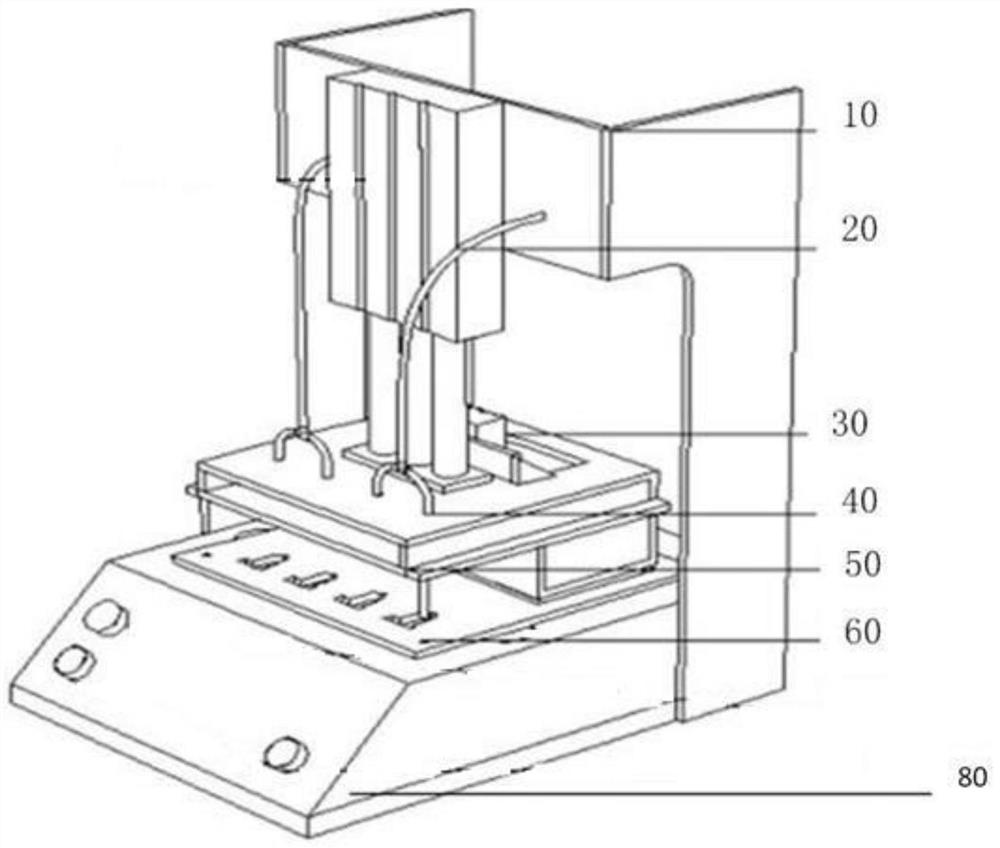

[0043] In view of the above problems, the embodiment of the present application provides an atomization plate detection device, which can replace the current manual detection of the atomization plate, and solve the problems of long detection ...

Embodiment 2

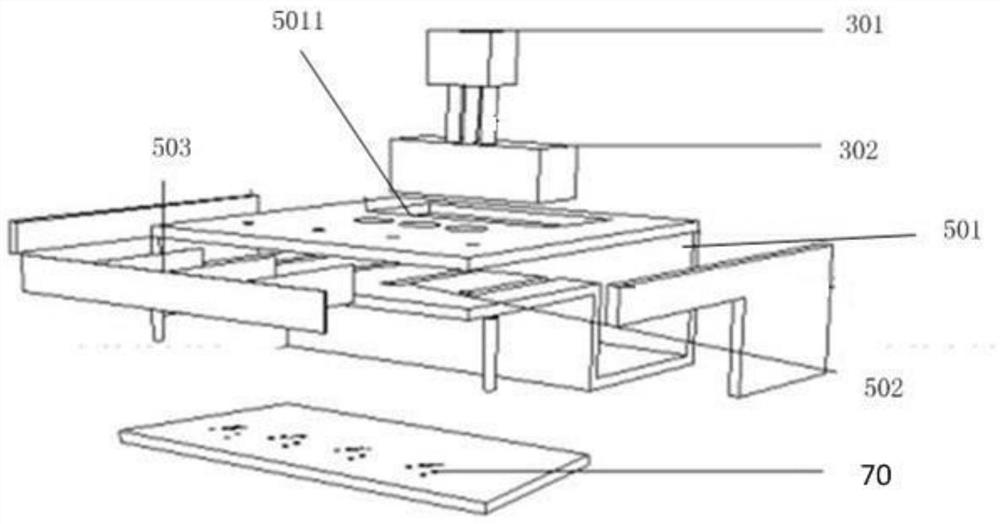

[0076] In practical application, when testing the atomization plate, it is necessary to wipe off the remaining water stains on the atomization plate after the detection is completed. In the prior art, the water stains are removed by manual wiping. In order to solve this problem, this embodiment also provides With the function of removing water stains. In addition to the atomizing plate tray 60 mentioned in the above embodiment, the first water tank 50, the lifting mechanism 20, the water supply mechanism 30, the probe top plate 70, and the device base 80, this embodiment also includes a water blowing air pipe 40;

[0077] The plate fitting part 502 is provided with a trachea through hole, and the nozzle of the water blowing air pipe 40 passes through the trachea through hole, and is set facing the atomizing plate tray 60 .

[0078] After the water blowing air pipe 40 completes the inspection of the atomizing plate, the water supply mechanism 30 is raised, and the water in the ...

Embodiment 3

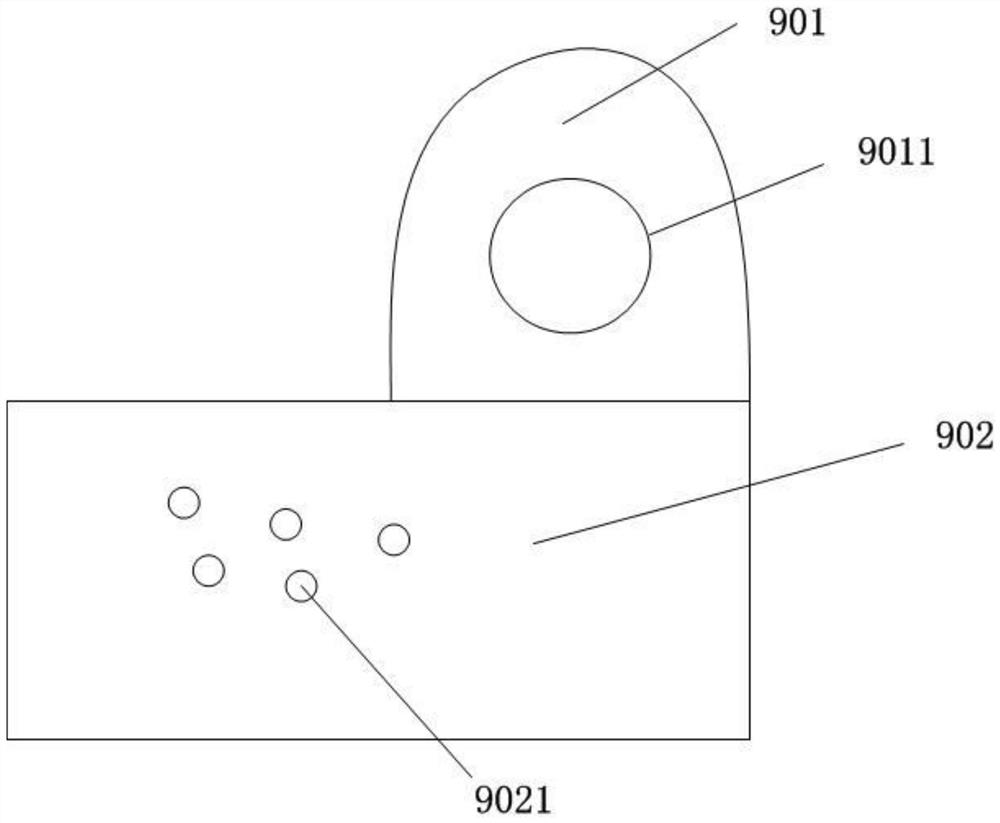

[0084] In addition, in practical applications, after the detection of the atomization plate is completed, it is necessary to affix a mark on the atomization plate according to the detection result. In the current technology, the method of manually pasting the mark is slow and inefficient. Therefore, this embodiment aims at This problem requires a detection device for an atomized plate. In addition to the structure of the above-mentioned embodiment 1 or 2, the device also includes:

[0085] The atomizing plate tray 60 is also provided with a stamping through hole; the device base 80 is provided with a stamping mechanism, which can pass through the stamping through hole and contact the atomizing plate to be tested.

[0086] The atomization plate tray 60 is provided with a stamping through hole, the size of the stamping through hole should match the stamping mechanism, so that the stamping mechanism can pass through the stamping through hole, and the position of the stamping through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com