A kind of inner curing type concrete preparation technology

A preparation process, concrete technology, applied in the field of inward curing concrete preparation technology, can solve the problems of concrete component strength differences, uneven steam curing effects, etc., and achieve the goals of reducing effect differences, improving curing uniformity, and improving curing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

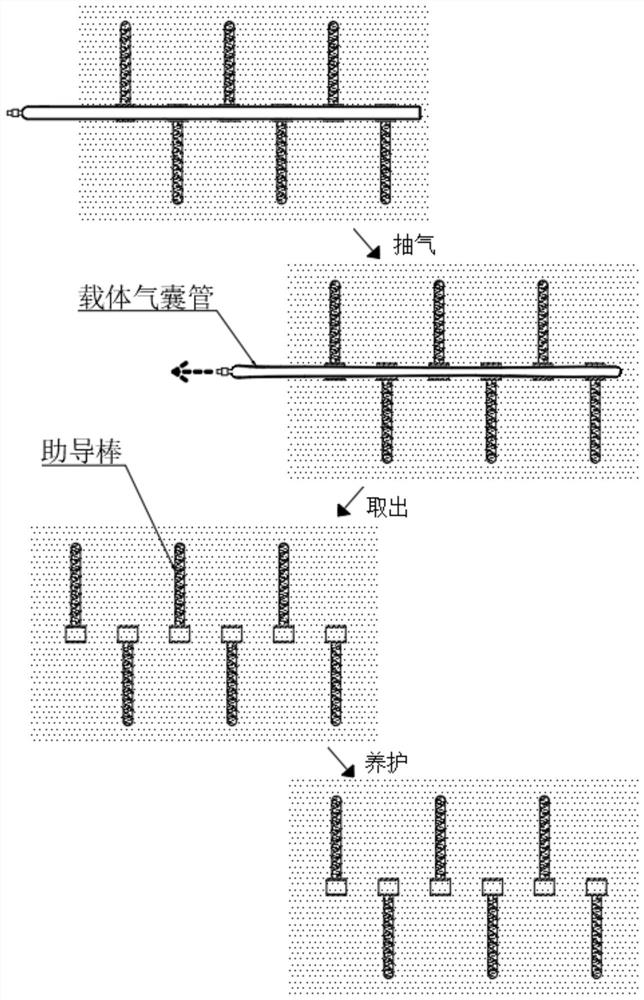

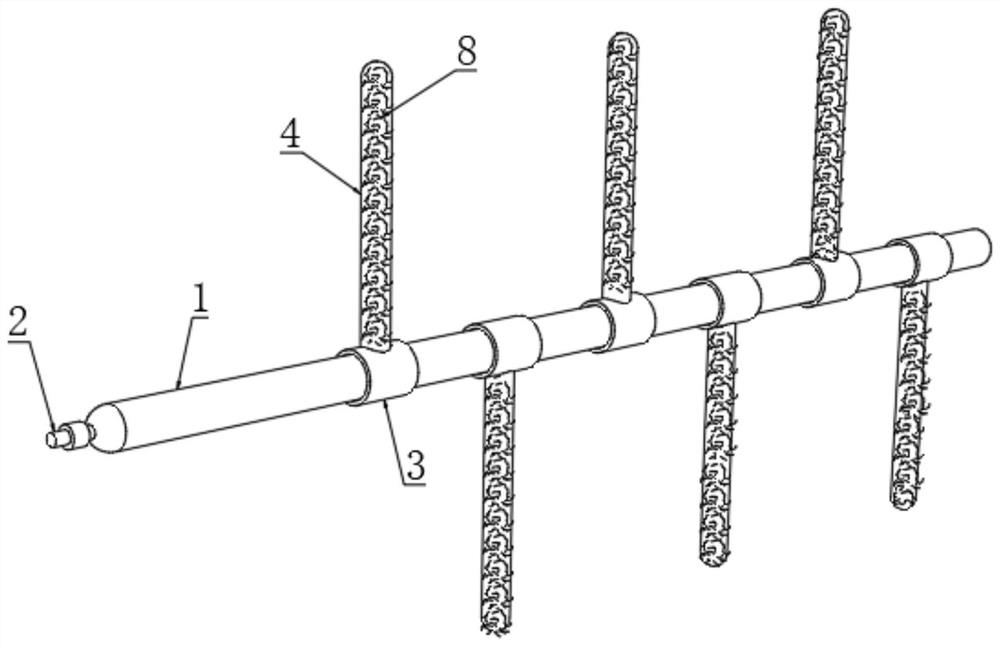

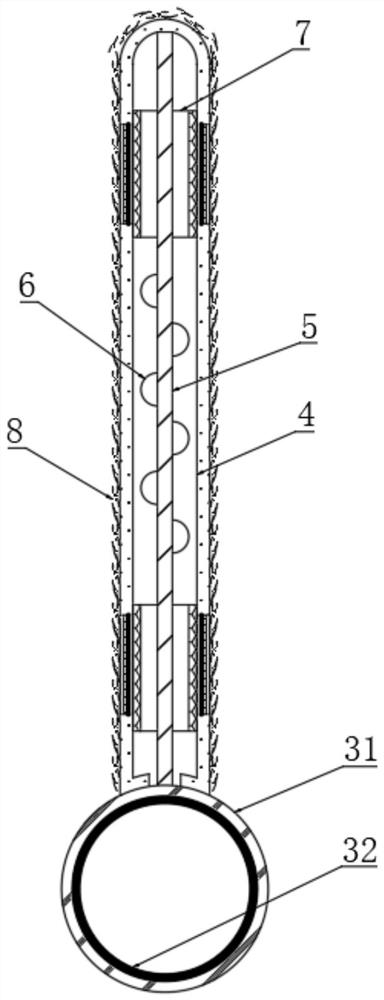

[0051] see figure 1 , an inner-curing concrete preparation process, including a guide pre-embedded device, the auxiliary guide embedded device includes a carrier air bag tube and a plurality of auxiliary guide rods, and the plurality of auxiliary guide rods are evenly sleeved on the outer end of the carrier air bag tube, Its preparation process includes the following steps:

[0052] S1. Concrete preparation: prepare the raw materials required for concrete preparation, and mix and stir various raw materials to prepare concrete slurry;

[0053] S2. Pre-embedding - pouring: put the entire guiding pre-embedder into the concrete precast mold in a horizontal and vertical state, then inject concrete slurry into the mold, and cover the upper part of the guiding pre-embedder;

[0054] S3. Take out-form: Slowly extract the gas in the carrier airbag tube, and then take out the carrier airbag tube from the concrete slurry. At the same time, the concrete slurry is vibrated to make the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com