A tire appearance detection device and its application method

A technology for appearance inspection and tires, applied in measurement devices, optical testing flaws/defects, instruments, etc., can solve problems such as difficulty in defining problems, increase in inspection time, low efficiency, etc., to achieve heat dissipation requirements, increase heat dissipation area, The effect of enhancing durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0094] It should be noted that the structures, proportions, sizes, etc. shown in the drawings attached to this specification are only used to match the content disclosed in the specification, for those who are familiar with this technology to understand and read, and are not used to limit the implementation of the present invention Any modification of structure, change of proportional relationship or adjustment of size shall fall within the range covered by the technical content disclosed in the present invention without affecting the effect and purpose of the present invention. within range.

[0095] At the same time, terms such as "upper", "lower", "left", "right", "middle" and "one" quoted in this specification are only for the convenience of description and are not used to limit this specification. The practicable scope of the invention and the change or adjustment of its relative relationship shall also be regarded as the practicable scope of the present invention without...

Embodiment 1

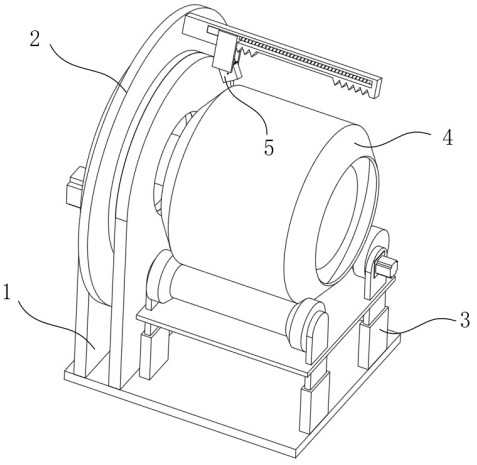

[0096] Embodiment 1, this embodiment provides a tire appearance detection device, combined with figure 1 , Figure 4 and Figure 25 , comprising a frame 1, a switching element 21, a turntable 22, a swing element 25, a detection assembly 5 and a control assembly 6, the turntable 22 and the swing element 25 are arranged above the frame 1, and the detection assembly 5 pairs the tire 4 with the control assembly 6. Internal visual inspection work.

[0097] combine Figure 4 and Figure 5 , the side near the center of the switch piece 21 is equipped with a turntable 22, the turntable 22 is connected to the swing piece 25 in rotation, and the switch piece 21 includes an annular block 211, an external tooth turn block 212, a linkage gear 213, an independent motor 214 and an internal gear Ring 215, the inner side of ring block 211 is set as inner toothed ring 215 structure, inner toothed ring 215 meshes with external tooth rotary block 212 through a plurality of linkage gears 213, ...

Embodiment 2

[0103] Embodiment 2, in addition to any content in the above embodiments, this embodiment also provides a tire appearance detection device, combined with figure 1 , Figure 4 and Figure 10 , also includes a driving assembly 3, a translation seat 23, a translation piece 24 and another detection assembly 5 fixed between the two first connecting plates 243, so as to realize the appearance detection of the inside and outside of the tire 4 at the same time, combined with Figure 25 In this structure, the output end of the controller 61 is also electrically connected to the linkage motor 14 , the translation motor 232 and the driving motor 35 .

[0104] combine figure 2 , the drive assembly 3 includes a lifting rod 31, a horizontal plate 32, a driven roller 33, a driving roller 34 and a drive motor 35, the bottom of the lifting rod 31 is vertically connected with the base 11, and the output ends of each lifting rod 31 are connected to the horizontal plate 32 Horizontally connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com