Automatic pressing device and method for pressing and retrieving materials

An automatic and platen technology, which is applied in metal processing and other directions, can solve problems that affect workpiece grasping, affect production efficiency, and workpieces cannot be grasped, and achieve the effect of ensuring stable operation, low cost, and solving intervention sorting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

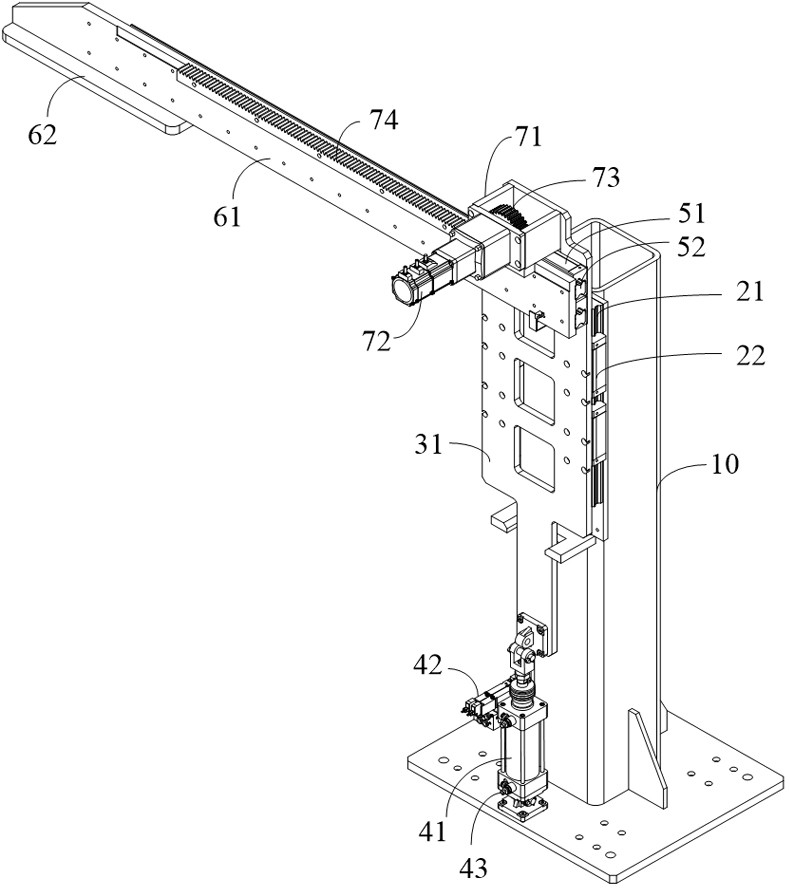

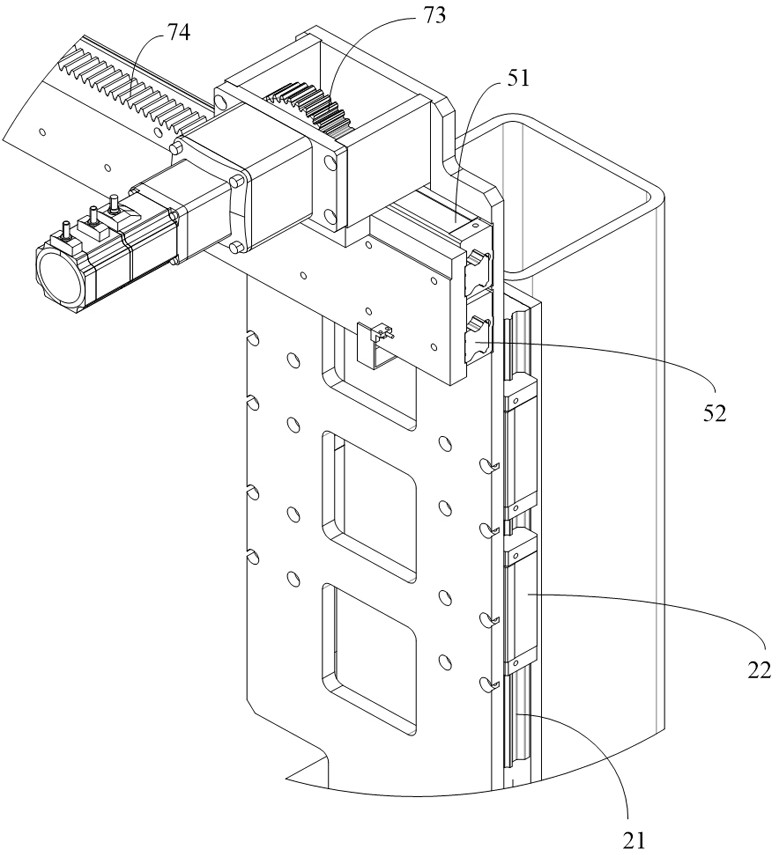

[0050] refer to figure 1 and figure 2 , the present invention proposes an automatic platen pressing device, which includes: a column 10, a mounting plate 31, a cylinder 41, a pressing plate 62, an X-axis driving assembly, an X-axis sliding assembly, and a Z-axis sliding assembly. Wherein, the column 10 is a direction steel column. The Z-axis sliding assembly includes a first slide rail 21 arranged on the column 10, and a first slide block 22 adapted to the first slide rail 21; a mounting plate 31 is arranged on the first slide block 22 The cylinder 41 is used to drive the mounting plate 31 to slide; the X-axis sliding assembly includes a second slider 51 arranged on the mounting plate 31 and a second slide rail 52 adapted to the second slider 51 The pressing plate 62 is connected to the second slide rail 52 ; the X-axis driving assembly is arranged on the mounting plate 31 for driving the pressing plate 62 to slide laterally.

[0051] Specifically, the automatic pressing p...

Embodiment 2

[0057] In another embodiment of the present invention, the automatic plate pressing device further includes a Y-axis sliding assembly and a Y-axis driving assembly arranged under the column 10; the Y-axis sliding assembly includes a third slide rail and a The third slide block adapted to the three slide rails, the column is arranged on the third slide block; the Y-axis drive assembly includes: a second rack set on the third slide rail, and a second rack set on the third slide rail The second motor on the third slider, and the second gear arranged on the shaft of the second motor, the second gear is adapted to the second rack. By setting the Y-axis sliding assembly and the Y-axis driving assembly, the degree of freedom of the device is further improved, so that the pressing plate can cover and press any area of the material plate.

[0058] The present invention has at least one of the following beneficial effects:

[0059] The present invention is mainly aimed at the problem...

Embodiment 3

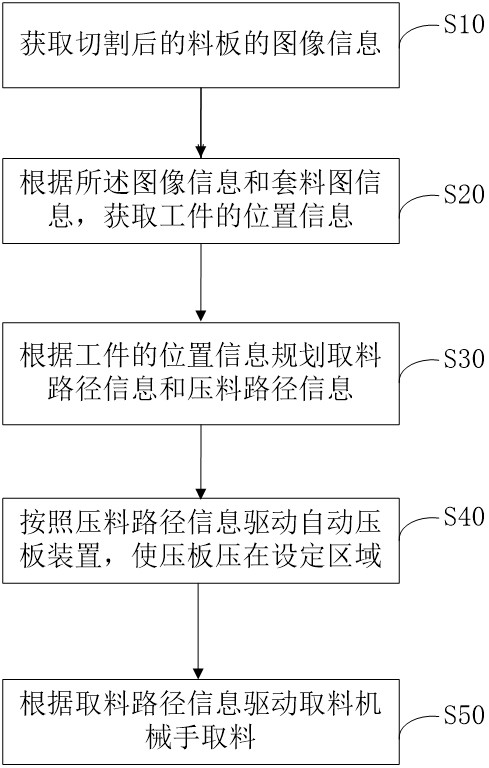

[0063] The present invention also proposes a method for pressing and retrieving materials, comprising the following steps:

[0064] S10 acquires the image information of the cut material plate; in this step, the image information of the cut material plate is obtained through the industrial camera arranged above the automatic plate pressing device, and the image information is transmitted to the visual recognition module through the PLC.

[0065] S20 obtains the position information of the workpiece according to the image information and nesting map information; the visual recognition module identifies the cut workpiece according to the image information of the material plate and the nesting map information in the PLC memory, thereby obtaining the position of each workpiece information. Specifically, the industrial camera takes pictures to obtain the image information of the workpiece, takes the camera as the origin, obtains the polar coordinate information of each pixel point ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com