Hinge assembly for folding screen

A technology of hinge assembly and flipping assembly, which is applied to electrical components, digital data processing parts, telephone structure and other directions, can solve the problems of increased folding thickness of mobile terminals, complex mechanical structure, and occupying installation space, and save installation space, High functional integration and improved damping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

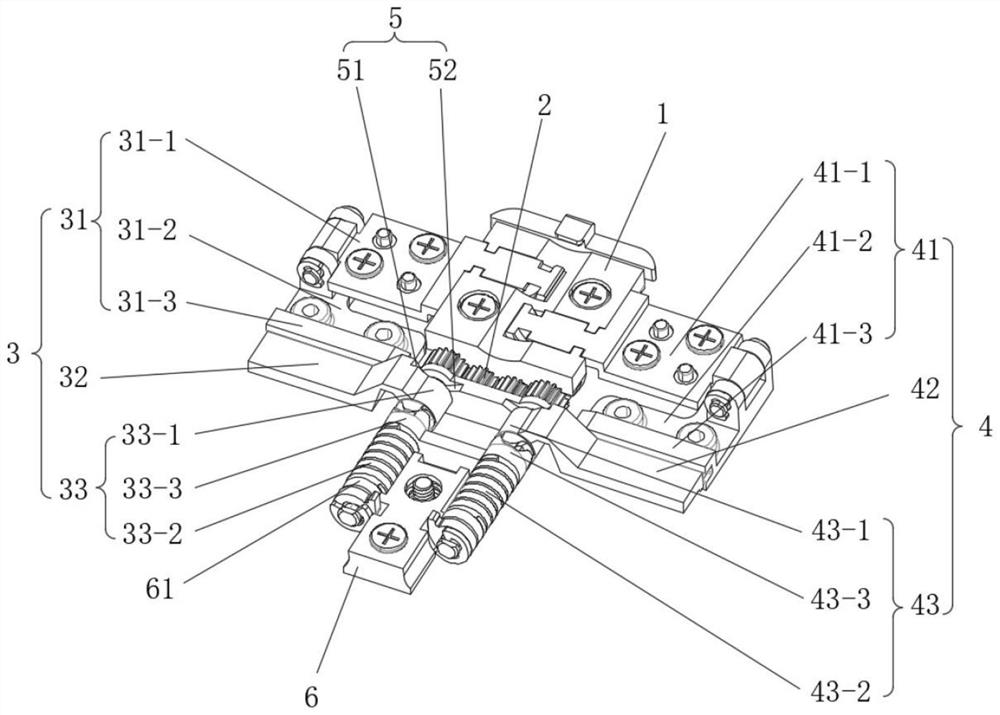

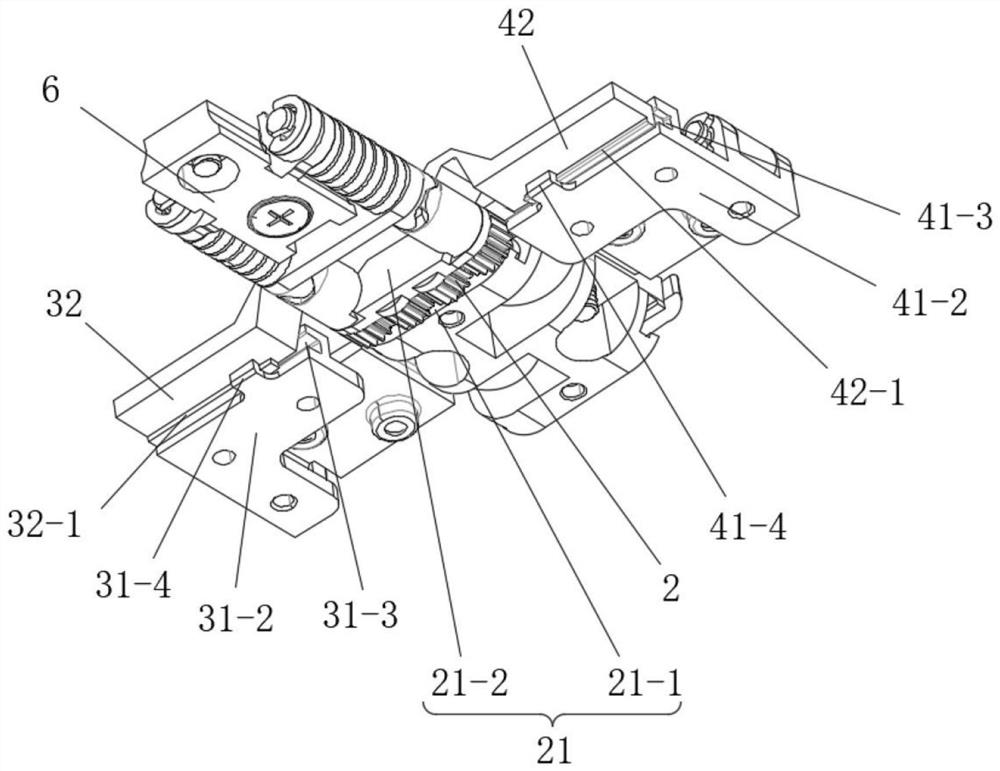

[0038] See Figure 1 to Figure 4 , the present invention includes a mounting base 1, and a left turning assembly 3 and a right turning assembly 4 which are rotatably arranged on the mounting base 1 and form a synchronous turning through an even numbered gear set 2.

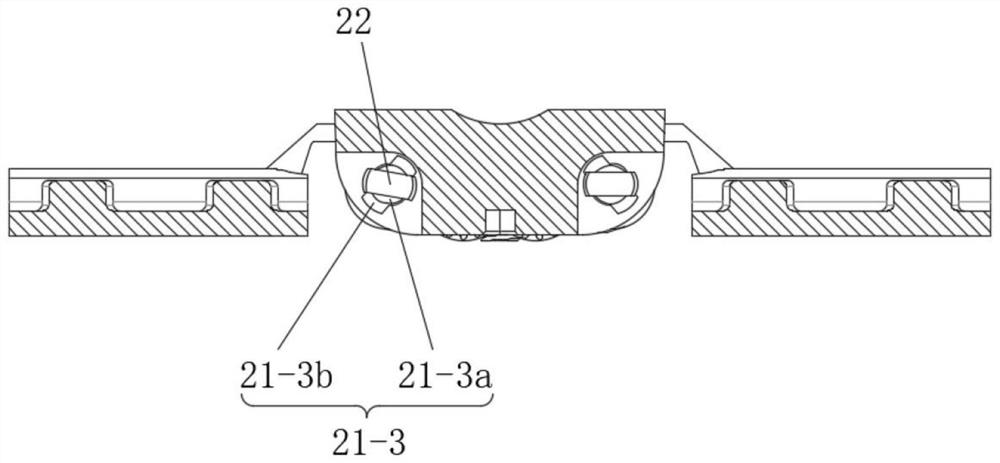

[0039] The left turning assembly 3 includes a left turning plate 31, a left turning plate 32 and a left damping member 33; the left turning plate 31 includes a first left connecting plate 31-1 for fixedly connecting the left support middle frame, and for fixing Connect the second left connecting plate 31-2 of the left side casing; one end of the first left connecting plate 31-1 is connected to the installation base 1 in rotation, and the other end is rotated with the second left connecting plate 31-2 through a rotating shaft connection; the second left connecting plate 31-2 is provided with a left chute 31-3; the even-numbered gear set 2 includes four gears that are rotated and arranged on the cage 21 for mutual tra...

Embodiment 2

[0049] See Figure 3 to Figure 6 In the present invention, the front and rear sides of the mounting base 1 are symmetrically provided with an even-numbered gear set 2, a left flap 32, a right flap 42, a left damper 33 and a right damper 43; There is a left chute 31-3 and a left buckle 31-4, and the front and rear sides of the right turning plate 41 are symmetrically provided with a right chute 41-3 and a right buckle 41-4; The leftmost gear on the even-numbered gear set 2 is connected in transmission, and the right flap 42 is connected to the rightmost gear on the even-numbered gear set 2 on the corresponding side; the left flap 32 is slidably arranged in the left chute 31-3 on the corresponding side , and through the left buckle 31-4 and the left flange 32-1 on the left flap 32 form a sliding connection that restricts the left flap 32 from leaving the left chute 31-3; the right flap 42 is slidably arranged on the right side of the corresponding side In the chute 41-3, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com