Method for preventing clamping stagnation and accumulation of vehicle safety belt at D ring

A seat belt and D-ring technology, applied in geometric CAD, electrical digital data processing, special data processing applications, etc., can solve problems such as seat belt function failure, seat belt jamming, cutting, etc., to reduce layout risks and improve stacking and stuck, the effect of shortening the development cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

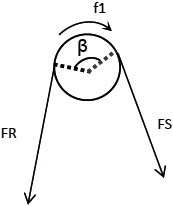

[0030] Example 1: Reference Figure 1-2 .

[0031] A method for preventing vehicle seat belts from being stuck and accumulated at the D ring,

[0032] Need to satisfy the formula

[0033] where μ 1 is the circumferential friction coefficient between the webbing and the D ring, that is, the friction coefficient between the seat belt and the surface of the D ring when the seat belt is pulled out normally, μ 2 is the axial friction coefficient between the webbing belt and the D ring, that is, the friction coefficient of the seat belt sliding back and forth relative to the D ring; α is the angle between the two webbing belts in the XZ plane, and β is the wrap angle between the webbing belt and the D ring.

[0034] The detailed design method is as follows:

[0035] The main purpose of the present invention is to provide a design method for the arrangement of key points of the seat belt, to ensure that the seat belt can pass through the D ring normally, and to avoid failure or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com