Noise reduction type spring mattress and manufacturing method thereof

A manufacturing method and noise reduction technology, applied in the field of mattresses, can solve the problems of large noise, noise, and large noise of speed springs that return to their original shape, and achieve the effects of improving sleep quality, good support effect, and improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

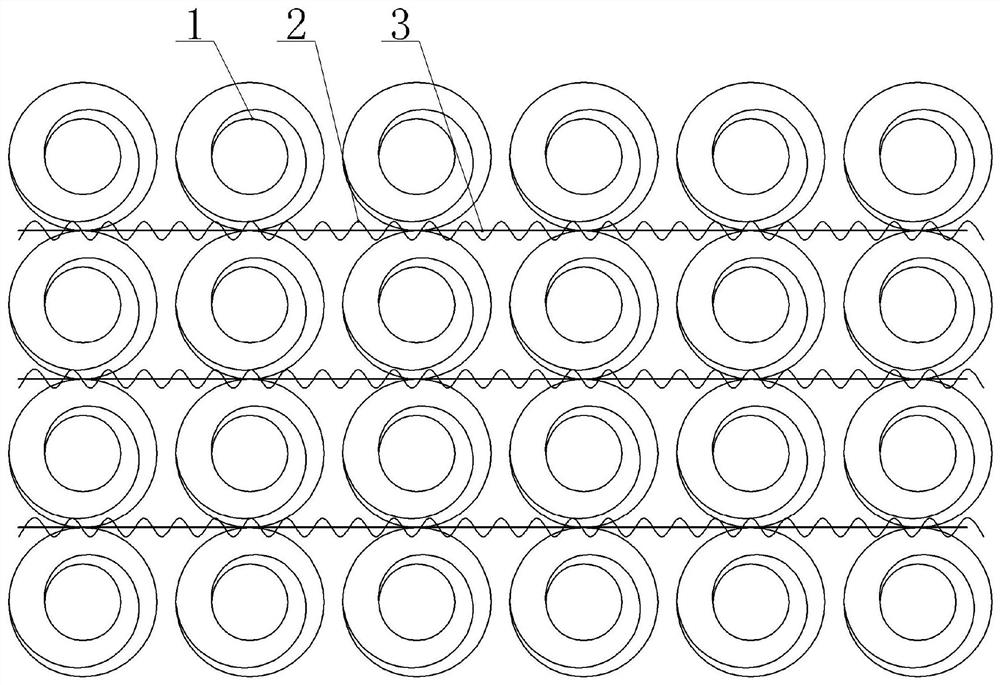

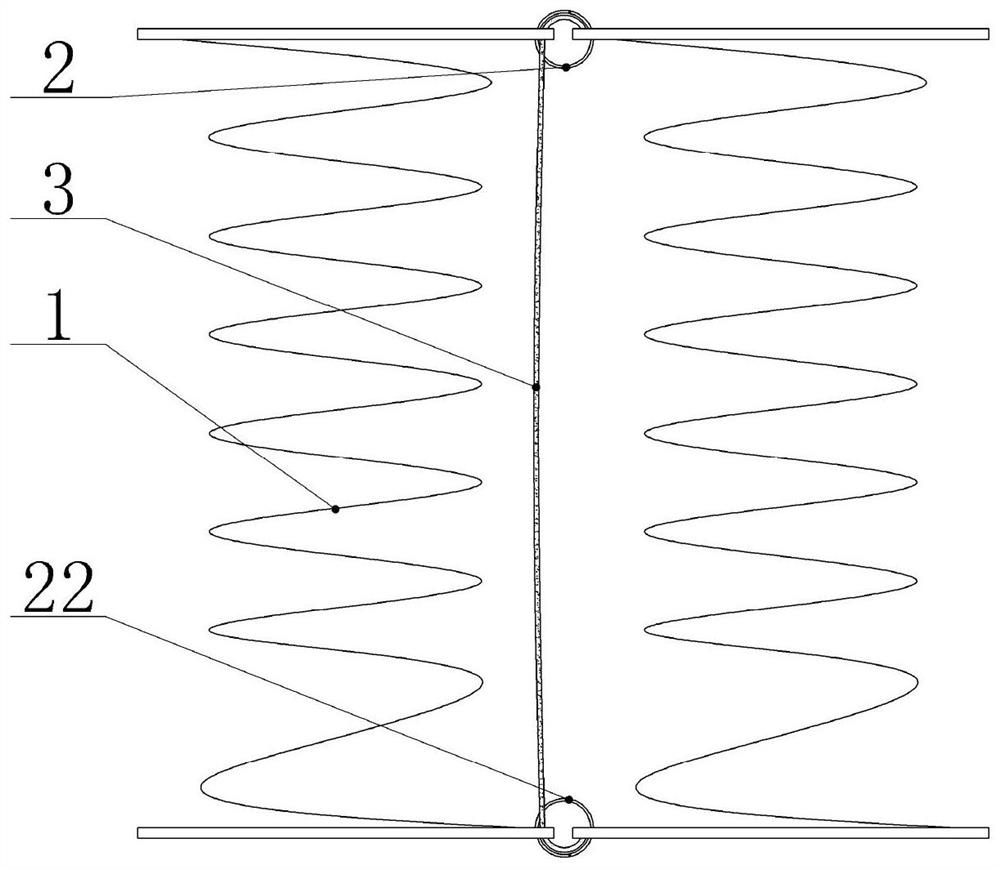

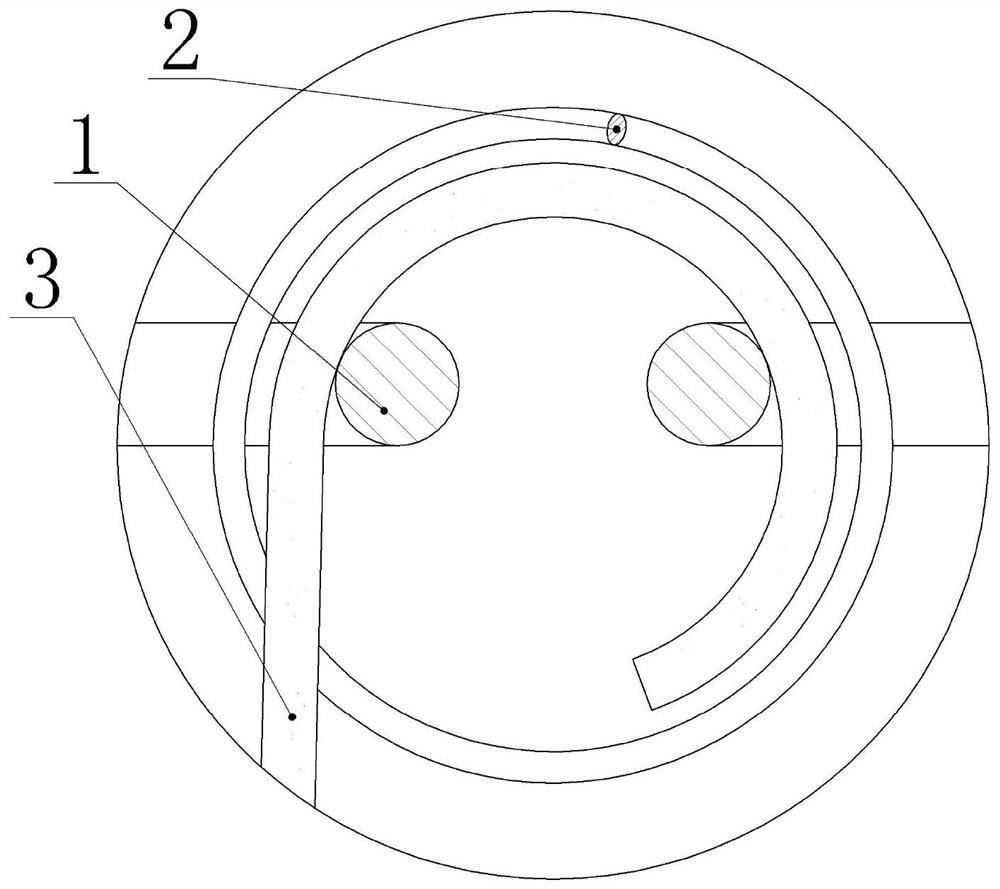

[0045] This embodiment discloses a noise-reducing spring mattress, which includes a cushion core, and the cushion core is covered with a surface layer (not shown in the figure). Some spring mattresses are generally provided with cushions such as sponge, latex, and cotton, which will not be described in detail in this embodiment. Such as figure 1 As shown, the pad core includes several elastic groups, and several elastic groups are arranged and distributed from bottom to top, and each elastic group includes several circular springs 1 arranged in sequence along the horizontal direction, and the circular springs 1 of adjacent elastic groups correspond one by one, A flexible layer 3 and two through-springs are arranged between adjacent elastic groups, and the through-springs are arranged horizontally. Specifically, the two through-springs are the upper through-spring 2 and the lower through-spring 22 respectively.

[0046] combine figure 2 with image 3 As shown, the height of...

Embodiment 2

[0057] On the basis of the noise-reducing spring mattress of Embodiment 1, the number of turns of the round spring 1 in this embodiment is 6 to 9 turns, the diameter of the middle waist is 40 to 50 mm, the diameter of the end is 53 to 65 mm, and the height 180-220mm. Specifically, the number of turns of the circular spring 1 selected in this embodiment is 8 turns, the diameter of the middle waist is 45mm, and the diameter of the end is 60mm.

[0058] The height of the circular spring 1 in this embodiment is relatively large, the deflection is relatively large, and the circular spring 1 is relatively soft, which can better fit the user's body curve, thereby improving the comfort of use, and the circular spring in this embodiment 1 Responses more sensitively under pressure. When the spring mattress adopting the circular spring 1 in this embodiment is in use, the user's chest and abdomen will vibrate during breathing and snoring. When the circular spring 1 is more sensitive , th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com